Production equipment and preparation method of slow-release bio-organic fertilizer

A bio-organic fertilizer and production equipment technology, which is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, organic fertilizers, etc., can solve the problems of inability to meet the heat generation requirements of waste incineration power generation, high moisture content of kitchen waste, and incinerator combustion. To achieve the effect of increasing beneficial bacteria and soil microorganisms and populations, alleviating obstacles to continuous cropping, and promoting and regulating crop growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

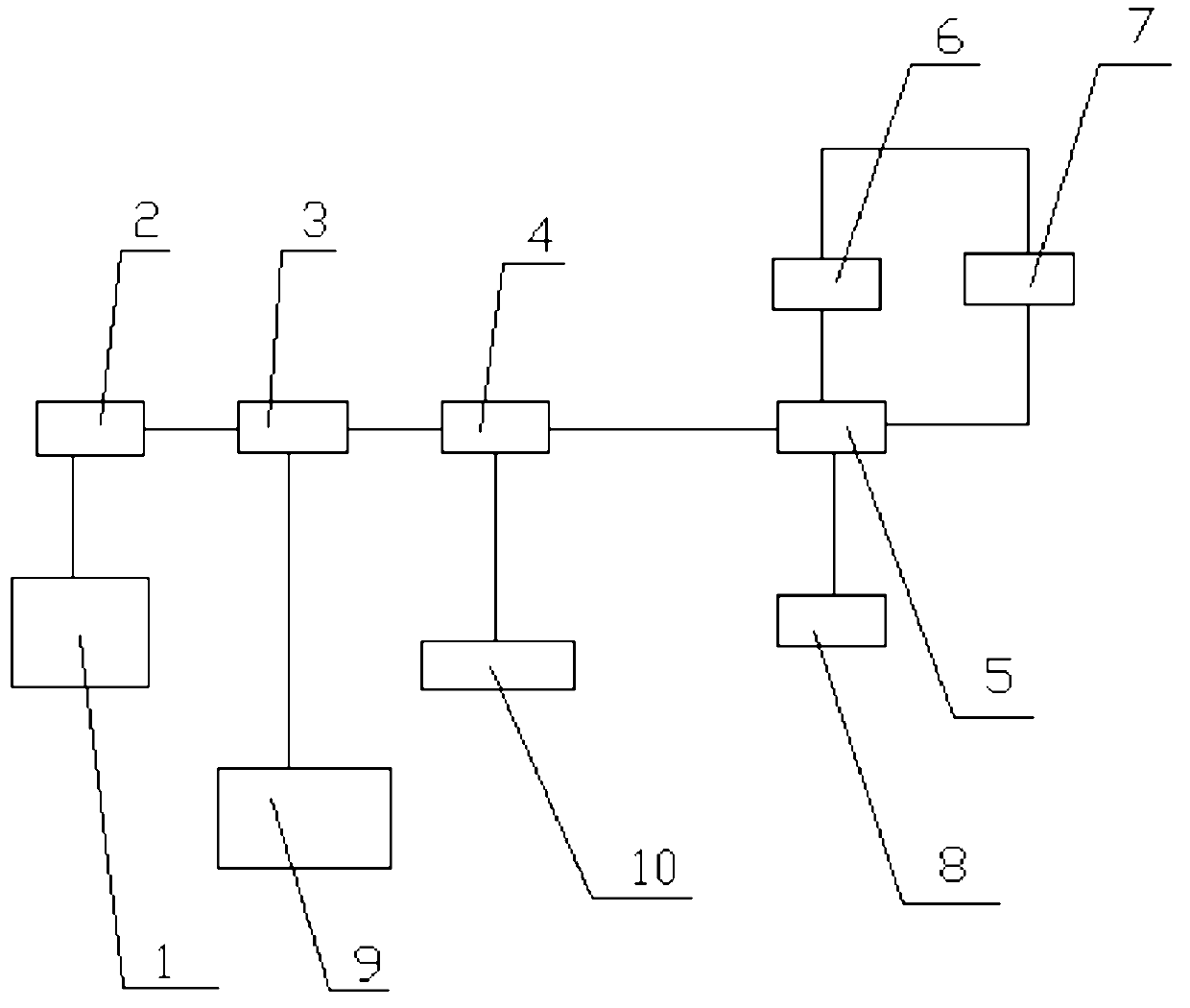

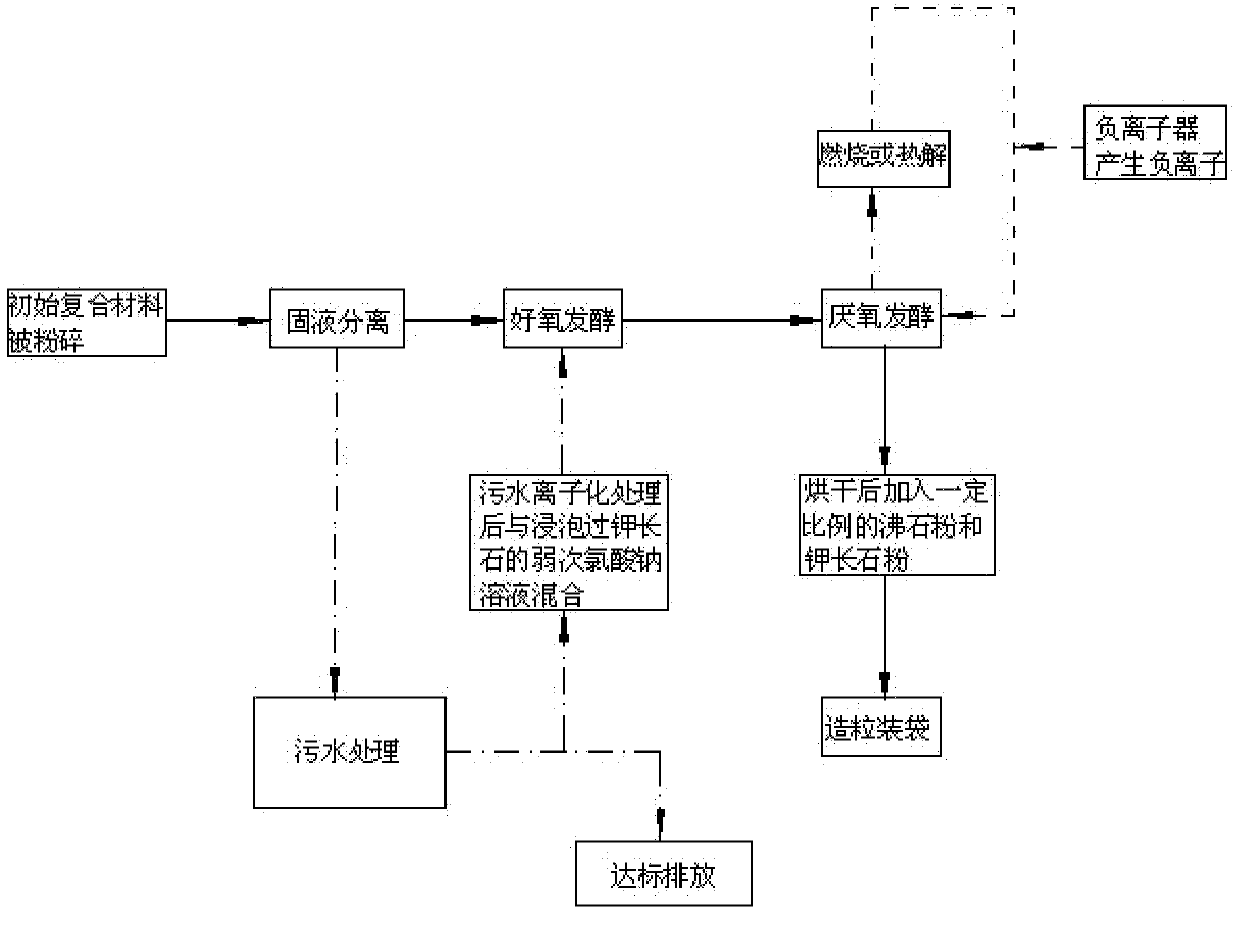

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0029] See figure 1 , a slow-release bio-organic fertilizer production equipment, including a pulverizer 2, a solid-liquid separator 3, an aerobic fermentation device 4, anaerobic fermentation device 5, a gas boiler (or garbage pyrolysis digester) 6, and an anion generator 7. Granulating and bagging device 8, modular sewage treatment system 9 and ionized water generator 10, pulverizer 2 is connected to solid-liquid separator 3 through pipelines, and solid-liquid separator 3 is connected to aerobic fermentation device 4 and modular The sewage treatment system 9 is connected, the ionized water generator 10 is connected between the modular sewage treatment system 9 and the aerobic fermentation device 4, the aerobic fermentation device 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com