Safe and environment-friendly initiating explosive substituent and preparation method thereof

A safety and environmental protection, primary explosive technology, applied in the direction of explosives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

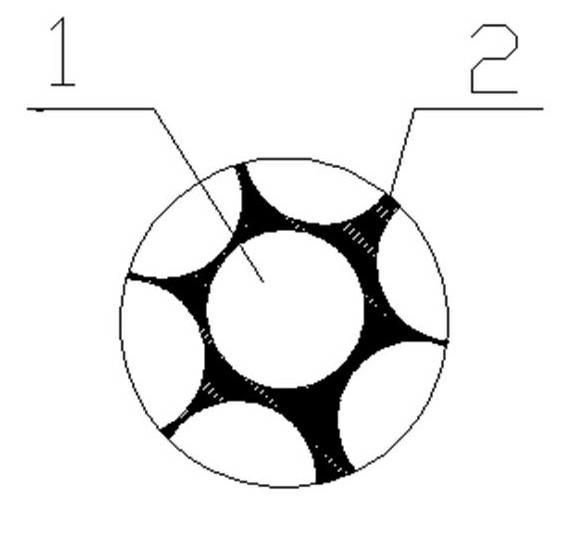

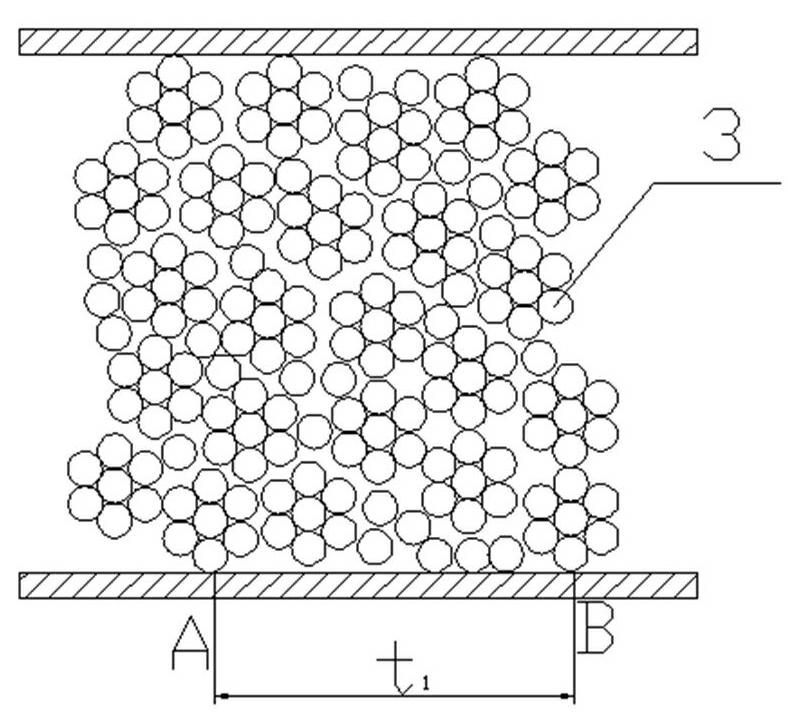

[0021] The fine-grain explosive uses ultra-fine ring trimethylenetrinitramine (ultra-fine RDX, SF-RDX), and the high-combustibility additive uses nano-thermite.

[0022] Fine particle RDX can be prepared by solvent-non-solvent method: dissolve 20g RDX in 200g DMF solvent, then spray the solution into low-temperature water, separate solid and liquid and dry to obtain superfine RDX explosive (SF-RDX) , with an average particle diameter of about 10 microns.

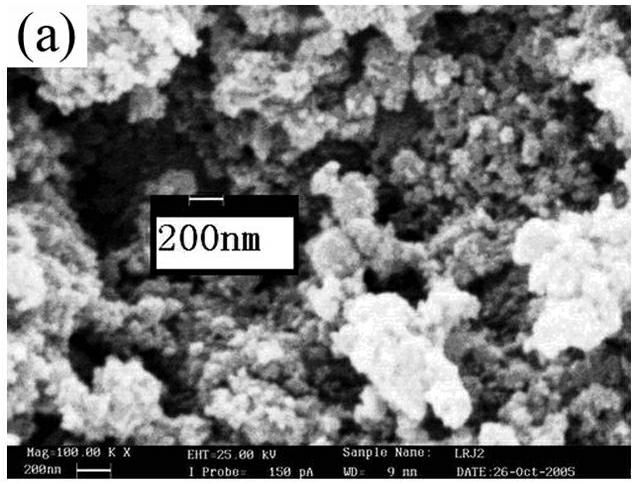

[0023] Al / Fe 2 o 3 The preparation of nano thermite can be carried out by ultrasonic mixing method, the commercial nano-Al powder with an average particle diameter of 50 nm and the commercial Fe powder with an average particle diameter of 30 nm 2 o 3 After the powder is weighed according to the stoichiometric ratio, they are added together into the n-hexane solvent, and shaken and mixed for 30 minutes under the action of ultrasonic waves to obtain the Al / Fe 2 o 3 The burning speed of nano-thermite is about 300m / s as tes...

Embodiment 2

[0027] The fine-grain explosive uses ultra-fine cyclotetramethylene tetranitramine (ultra-fine Octojin, SF-HMX), and the high-combustibility additive uses Al / CuO nano-thermite.

[0028] SF-HMX was prepared using HMX as a raw material and DMF as a solvent, referring to the method for preparing SFRDX in Example 1, and the average particle diameter of the obtained SFHMX was about 5 microns.

[0029]Al / CuO nanometer thermite prepares Al / Fe with reference to Example 1 2 o 3 The method is carried out, wherein the raw material CuO has an average particle size of 40nm, and the Al / CuO nano thermite test burning velocity is about 350m / s.

[0030] The preparation of SF-HMX: Al / CuO refers to the ultrasonic mixing method in Example 1, the mass ratio of SF-HMX: Al / CuO is 6:4, and the core / shell type primer substitute is obtained.

[0031] Refer to Example 1 for the detonation test method of the detonating agent substitute in Example 2, and the test results are shown in Table 1.

Embodiment 3

[0033] SF-RDX is used as the fine-grained explosive, and Al / NiO nano-thermite is used as the high-combustibility additive.

[0034] Except that NiO was used as the oxidizing agent in the nano-thermite, the preparation of other materials was carried out with reference to the method of Example 1. Wherein the average particle size of NiO is 50 nanometers, and the tested burning velocity of the obtained Al / NiO nano thermite is about 200m / s. The mass ratio of SF-PETN: Al / NiO is 7:3, and the core / shell type primary explosive substitute is obtained.

[0035] Refer to Example 1 for the detonation test method of the primer substitute in Example 3, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com