Method for preparing diethyl diaminotoluene

A technology of diethyldiaminotoluene and diaminotoluene, which is applied in the field of preparation of diethyldiaminotoluene, can solve the problems of equipment corrosion environment and pollution, achieve high atom utilization, reduce equipment cost, and save raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

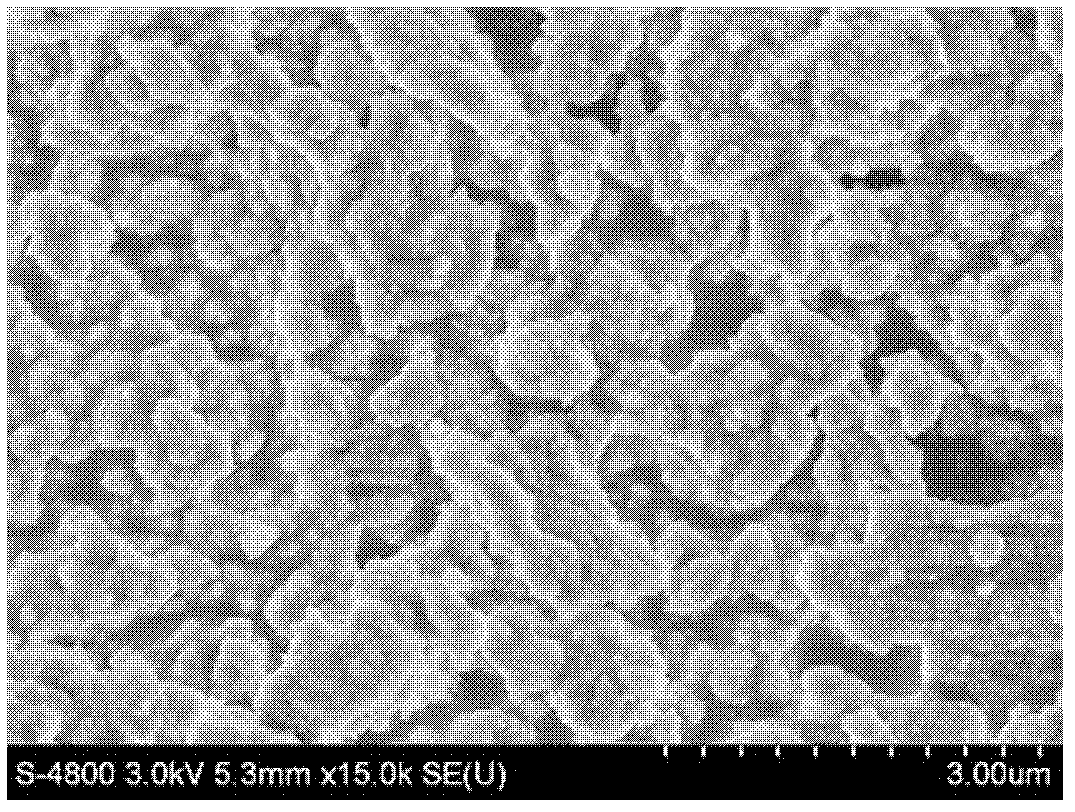

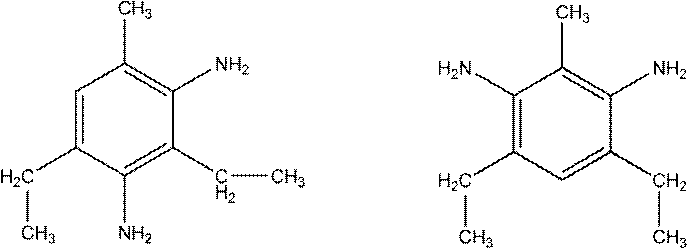

Method used

Image

Examples

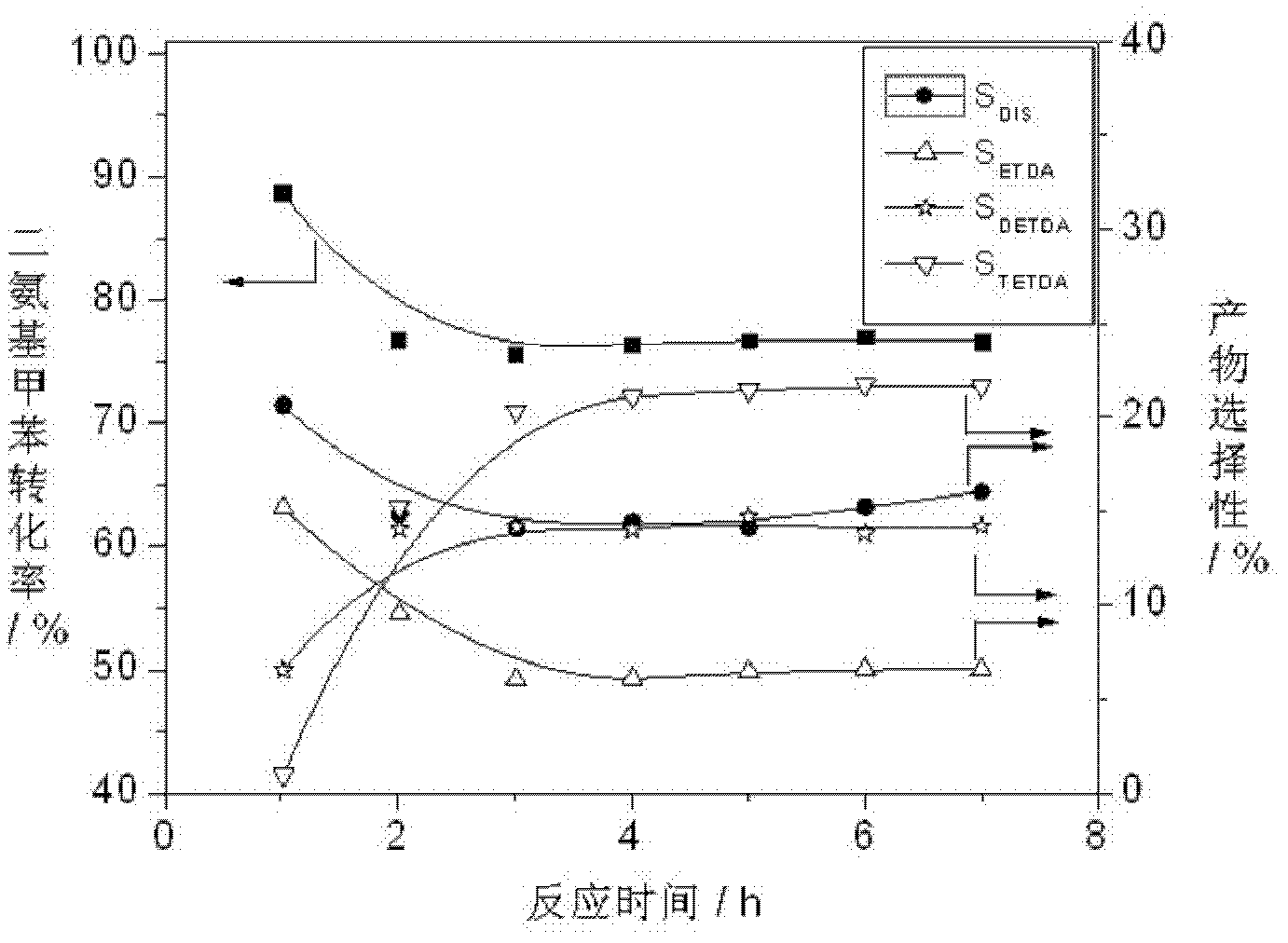

Embodiment 1

[0042] Add 10.0g of 2,4-diaminotoluene and 48mL of ethanol into a 100mL stainless steel batch reactor, stir and dissolve, add 1.0g of nano-scale HZSM-5 molecular sieve, heat to 330°C, react for 5h, take out the product at 1500 After centrifuging for 2 min at a speed of rpm, the upper layer liquid was taken for chromatographic analysis, and the results are shown in Table 1 (A).

Embodiment 2

[0044] The reaction steps are the same as in Example 1, but the reaction time is changed to 10h, and the product is subjected to chromatographic analysis, and the results are shown in Table 1 (B).

Embodiment 3

[0046] Add 10.0g of 2,4-diaminotoluene and 48mL of ethanol into a 100mL stainless steel batch reactor, stir and dissolve, add 1.0g of mordenite (HM), heat to 330°C, react for 5h, take out the product at 1500 rpm Centrifuge at a speed of 2 min for 2 min, and take the upper liquid for chromatographic analysis, the results are shown in Table 1 (C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com