Method and device for producing clomazone

A technology of clomazone and tubular reactor, which is applied in the direction of organic chemistry, can solve the problems of unfavorable stable production of clomazone, unstable product quality, and small capacity of a single set of equipment, so as to achieve shortened reaction time and high product quality. Increased yield and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

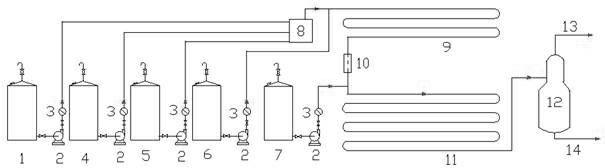

[0025] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises a large tank 1 of hydroxylamine hydrochloride solution, a large tank 4 of chlorpivaloyl chloride and a large tank 5 of o-chlorobenzyl chloride, and the three large tanks are respectively communicated with a mixer 8 through a feed pump 2, and the mixer 8 is communicated with Low temperature tubular reactor 9, liquid caustic soda tank 6 is communicated with the feed pipe of low temperature tubular reactor 9 by feed pump 2, and low temperature tubular reactor 9 is connected with high temperature tubular reactor 11 by preheater 10, A stratifier 12 is connected to the outlet of the high temperature tubular reactor 11; a waste water treatment pipe 13 is arranged on the outlet of the top end of the stratifier 12, and a thin film evaporation tube 14 is arranged on the outlet of the bottom end; the low temperature tubular reaction A frozen brine cooling pipe is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com