Polyester glue specially used for compounding PET (polyethylene terephthalate) film and PE (polyethylene) film of solar cell backboard and method for preparing same

A solar cell and film compounding technology, applied in the field of solar cells, can solve the problems of high weather resistance and composite strength of glue, which cannot meet such requirements, and achieve high composite peeling strength, simple method, and excellent barrier performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

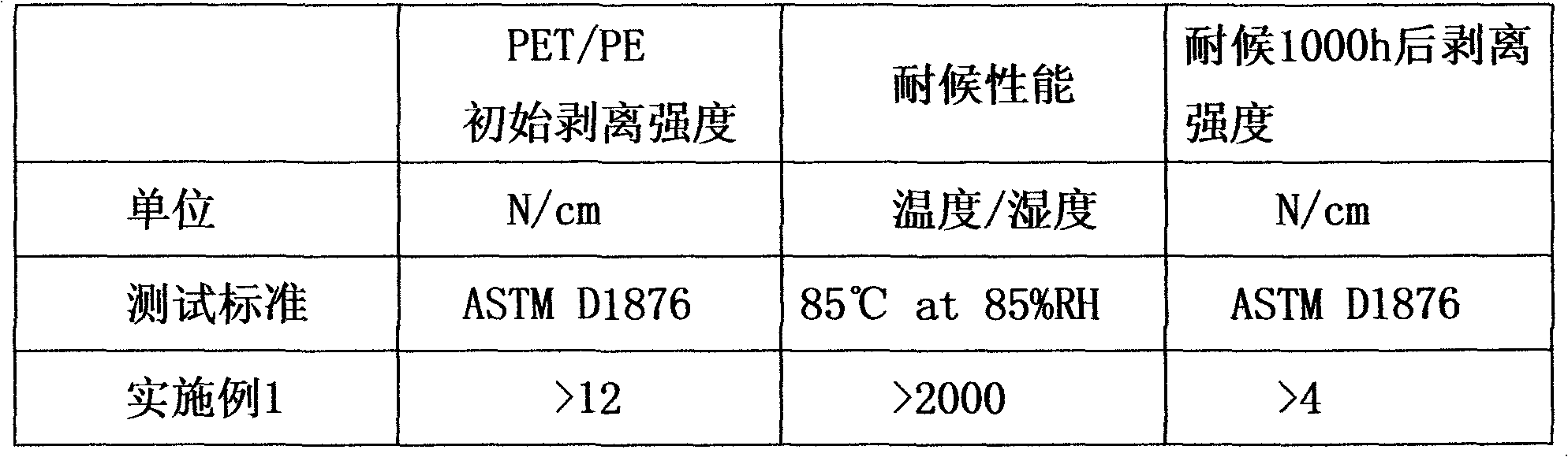

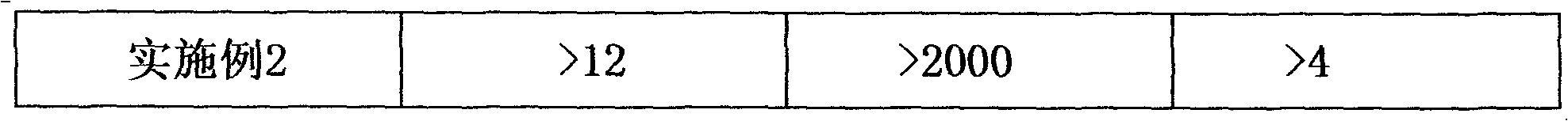

Embodiment 1

[0024] A special polyester glue for solar cell backplane PET and PE film compounding and preparation method thereof, wherein the polyester glue content is 20%; the ethyl acetate content is 76.8%; the curing agent content is 2%; polyester glue: curing Agent=10:1; antioxidant content is 0.2%; anti-UV agent content is 0.4%; leveling agent content is 0.4%; silane coupling agent content is 0.2%;

[0025] Add polyester glue, ethyl acetate, antioxidant, leveling agent, silane coupling agent, and anti-UV agent into the stirring tank according to the raw material formula. into a transparent solution; then add the curing agent into the stirring tank and continue stirring for 1 to 2 hours, and then the polyester glue can be prepared;

[0026] Coat the polyester glue on one side of the base layer of the PET film, dry it at a certain temperature, and the thickness of the dry glue is 8um, and then hot-press and compound the glue-coated surface of the PET film and the PE film layer at a cert...

Embodiment 2

[0028] A special polyester glue for solar cell backboard PET and PE film compounding and preparation method thereof, wherein the polyester glue content is 35%; the ethyl acetate content is 60%; the curing agent content is 3.5%; polyester glue: curing agent =10:1; the content of antioxidant is 0.4%, the content of anti-UV agent is 0.6%, the content of leveling agent is 0.3%; the content of silane coupling agent is 0.2%.

[0029] Add polyester glue, ethyl acetate, antioxidant, leveling agent, silane coupling agent, and anti-UV agent into the stirring tank according to the raw material formula. into a transparent solution; then add the curing agent into the stirring tank and continue stirring for 1 to 2 hours, and then the polyester glue can be prepared;

[0030] Coat the polyester glue on one side of the base layer of the PET film and dry it at a certain temperature. The thickness of the dry glue is 12um. The solar battery back sheet film can be prepared by aging.

[0031] Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com