Electronic protecting glue, and preparation method and application thereof

A technology of electronic protection and protective glue, which is applied in the direction of adhesives, adhesive types, coatings, etc., can solve the problems of poor UV resistance and moisture resistance, poor bonding performance, and use restrictions, and achieve UV resistance and moisture resistance. Excellent, low equipment requirements, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

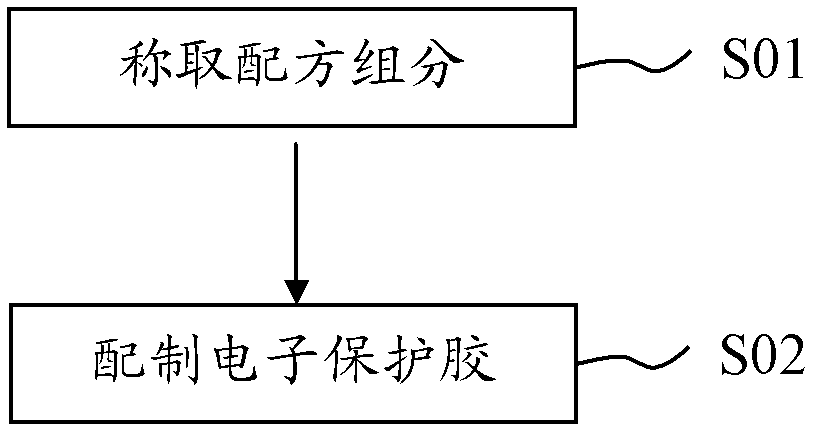

[0029] The embodiment of the present invention also provides the preparation method of above-mentioned electronic protective adhesive, and its technological process is as follows figure 1 shown. The method comprises the steps of:

[0030] S01. Weigh the formula components: weigh each component according to the formula of the above-mentioned electronic protective glue;

[0031] S02. Preparation of electronic protective glue: adding alkyd resin, amino resin, and silicone resin to the protective colloid solvent to dissolve and disperse evenly, and then packaging to obtain the electronic protective glue.

[0032] Specifically, in the above step S01, the formula of the electronic protection glue and the preferred content and types of each component in the formula are as described above, and will not be repeated here to save space.

[0033] In the above step S02, the method of dissolving alkyd resin, amino resin, silicone resin and other components adopts a high-speed dispersion s...

Embodiment 1

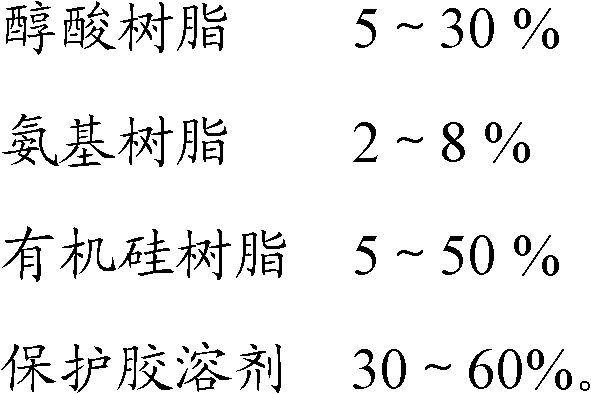

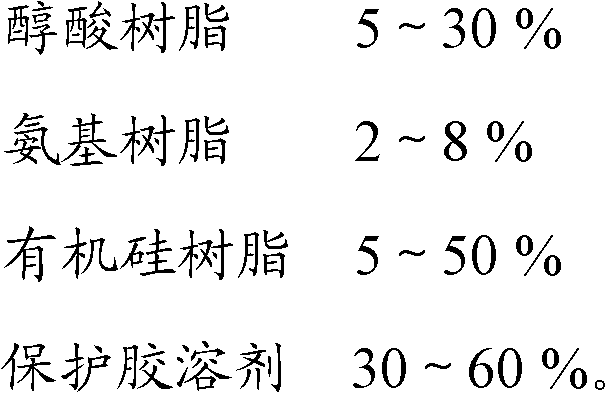

[0038] The formula component of the weight percentage of electronic protective glue is as follows:

[0039]

[0040] The preparation method of this electronic protective glue is as follows:

[0041] S11: Weigh each component according to the formula of the above-mentioned electronic protective glue;

[0042] S12: Add the alkyd resin, amino resin, and silicone resin among the above components into a protective colloid solvent to dissolve and disperse evenly, then filter and pack to obtain the electronic protective colloid.

[0043] After the electronic protective glue prepared in this example is used for the circuit board to be immersed in the protective glue and cured to form a film, the measured insulation resistance value is 5.8×10 11 Ω. After 168 hours in a constant temperature and humidity box at 85°C and 85% RH, the measured insulation resistance value is 5.2×10 11 Ω, the insulation resistance value basically does not change, and other performances are detected to b...

Embodiment 2

[0045] The formula component of the weight percentage of electronic protective glue is as follows:

[0046]

[0047] The preparation method of the electronic protective glue is the same as the preparation method in Example 1.

[0048] After the electronic protective glue prepared in this example is used for LED circuit boards to be immersed in the protective glue and cured to form a film, the measured insulation resistance value is 7.3×10 10 Ω. After 168 hours in a constant temperature and humidity box at 85°C and 85% RH, the measured insulation resistance value is 6.5×10 10 Ω, the insulation resistance value basically does not change, and other performances are detected to be normal, meeting the requirements for protecting circuit boards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com