Method for preparing water-proof and moisture permeable coated fabrics

A coating fabric, waterproof and moisture-permeable technology, applied in the textile field, can solve the problems of many influencing factors and the inability to use general coatings, and achieves the effect of simple process, satisfying wearing comfort requirements, and improving moisture-permeability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

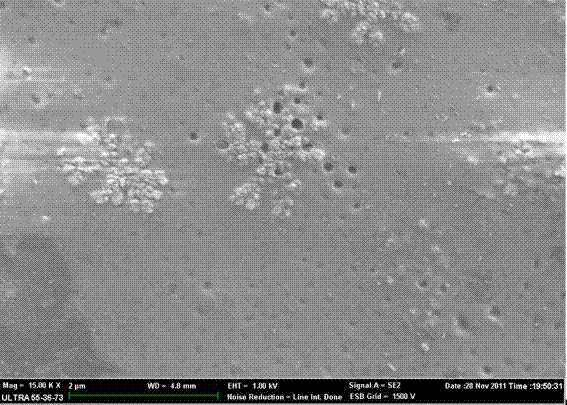

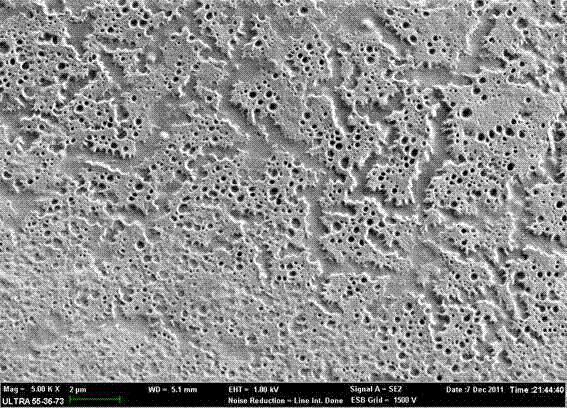

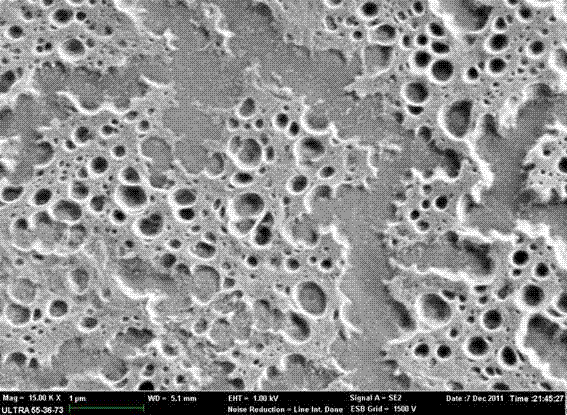

Image

Examples

example 1

[0040] Example 1. Different coating amounts

[0041](1) Pre-water-repellent finishing of polyester fabric: pre-water-repellent finishing of polyester fabric, the process formula and conditions are: water-repellent agent TG-410C 20g / L; bath ratio 1:15; dipping time is 5min; one soaking and one rolling , The liquid squeeze rate is 70%; the pre-baking temperature is 100°C, and the time is 3min; the baking temperature is 160°C, and the time is 1min.

[0042] (2) Coating finishing: use the following coating agent to coat the polyester fabric,

[0043] Coating agent: (the thickener is polyanionic cellulose PAC, and its degree of substitution is 0.85-1.4)

[0044] Water-based PA coating agent DS 330: 100 parts,

[0045] Polyanionic cellulose PAC (diluted 1:20 with water): 20 parts,

[0046] Silicone surfactant BYK-346: 6 parts,

[0047] The pre-baking temperature is 90°C, and the pre-baking time is 3 minutes;

[0048] The baking temperature is 140°C, and the baking time is 60s...

example 2

[0050] Example 2. Different baking temperatures

[0051] (1) Pre-water-repellent finishing of polyester fabric: pre-water-repellent finishing of polyester fabric, the process formula and conditions are: water-repellent agent TG-410C 20g / L; bath ratio 1:15; dipping time is 5min; one soaking and one rolling , The liquid squeeze rate is 70%; the pre-baking temperature is 100°C, and the time is 3min; the baking temperature is 160°C, and the time is 1min.

[0052] (2) Coating finishing: use the following coating agent to coat the polyester fabric,

[0053] Coating agent: (the thickener is polyanionic cellulose PAC, and its degree of substitution is 0.85-1.4)

[0054] Water-based PA coating agent DS 330: 100 parts,

[0055] Polyanionic cellulose PAC (diluted 1:20 with water): 20 parts,

[0056] Silicone surfactant BYK-346: 6 parts,

[0057] The coating amount is about: 4.8g / ㎡,

[0058] The pre-baking temperature is 90°C, and the pre-baking time is 3 minutes;

[0059] The bak...

example 3

[0061] Example 3. Different baking time

[0062] (1) Pre-water-repellent finishing of polyester fabric: pre-water-repellent finishing of polyester fabric, the process formula and conditions are: water-repellent agent TG-410C 20g / L; bath ratio 1:15; dipping time is 5min; one soaking and one rolling , The liquid squeeze rate is 70%; the pre-baking temperature is 100°C, and the time is 3min; the baking temperature is 160°C, and the time is 1min.

[0063] (2) Coating finishing: use the following coating agent to coat the polyester fabric,

[0064] Coating agent: (the thickener is polyanionic cellulose PAC, and its degree of substitution is 0.85-1.4)

[0065] Water-based PA coating agent DS 330: 100 parts,

[0066] Polyanionic cellulose PAC (diluted 1:20 with water): 20 parts,

[0067] Silicone surfactant BYK-346: 6 parts,

[0068] The coating amount is about: 4.8g / ㎡,

[0069] The pre-baking temperature is 90°C, and the pre-baking time is 3 minutes;

[0070] The baking temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com