Method for realizing high absorption efficiency of Nd:YAG laser for pumping light

A pump light, high absorption technology, applied in the field of Nd: yag laser, can solve the problem that the spectral line width pump light energy cannot be absorbed, achieve excellent thermal conductivity and photoelectric performance, and improve the effect of energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

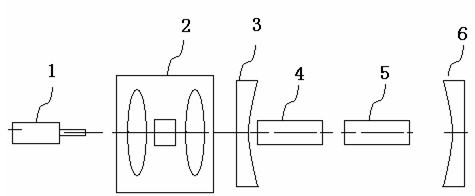

[0030] Such as figure 1 As shown, a Nd: yag laser method for achieving high absorption efficiency of pump light, including a laser diode pump source 1, a laser resonator 12, a first laser medium 4, the first laser medium is Nd: YAG, along In the direction of pump light propagation, there is a second laser medium 5 behind the first laser medium 4, and the second laser medium 5 is Nd:YVO4. The second laser medium 5 is used to absorb the pump light. When all the pump light passes through the first laser medium 4, the pump light power within the first laser medium 4 (Nd: YAG crystal 808.6nm wavelength absorption spectrum) will be completely is absorbed, and the pump light power outside the first laser medium 4 (Nd: YAG crystal absorption spectrum |) enters the second laser medium 5 (Nd: YVO 4 crystal), absorbed by the second laser medium 5.

[0031] When working, the laser diode pump source 1 enters the optical coupling unit 2 with a certain spatial distribution, and injects t...

Embodiment 2

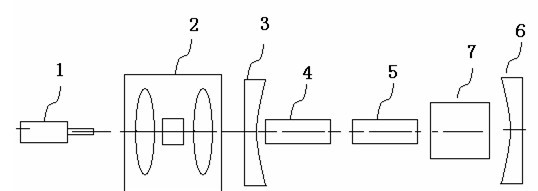

[0034] figure 2 Given another example, it is the same as figure 1 The difference is that a Q-switch 7 is placed inside the output mirror 6 of the resonator, and the Q-switch 7 is used to realize the Q-switch pulse output of the Nd:YAG laser. The role of the second laser medium 5 (Nd: YVO4 medium) is the same as figure 1 exactly the same.

Embodiment 3

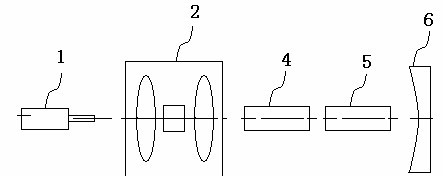

[0036] exist image 3 In the first laser medium 4, the optical reflection film is coated on one side of the pump light end face to form a resonant cavity mirror, eliminating the need for figure 1 and figure 2 The resonator mirror 3 in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com