High-efficiency vertical cavity surface emitting semiconductor laser with asymmetric optical field distribution

A technology of vertical cavity surface emission and light field distribution, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of high loss, laser conversion efficiency limitation, etc., to increase output power, improve optical loss, and improve conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

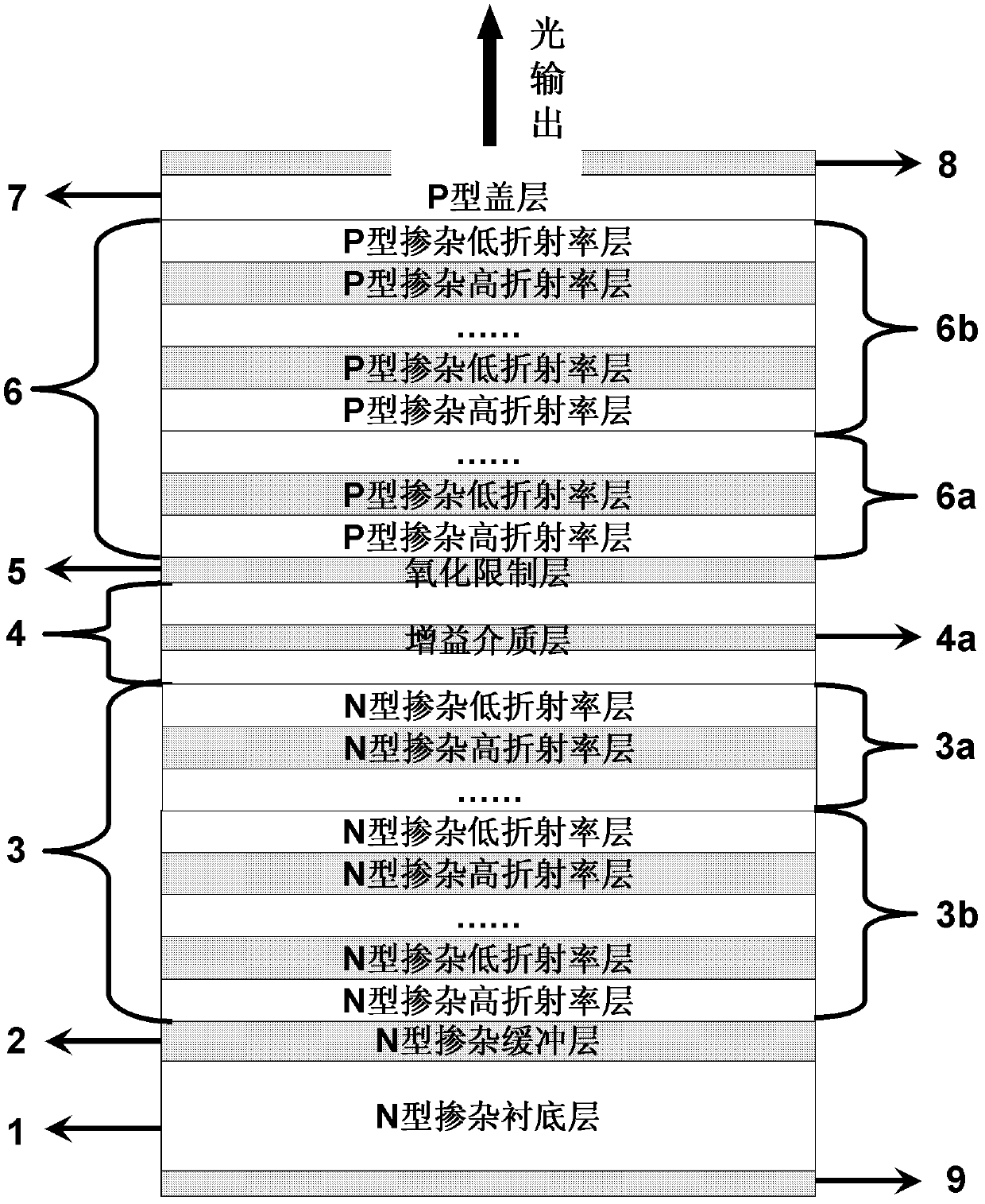

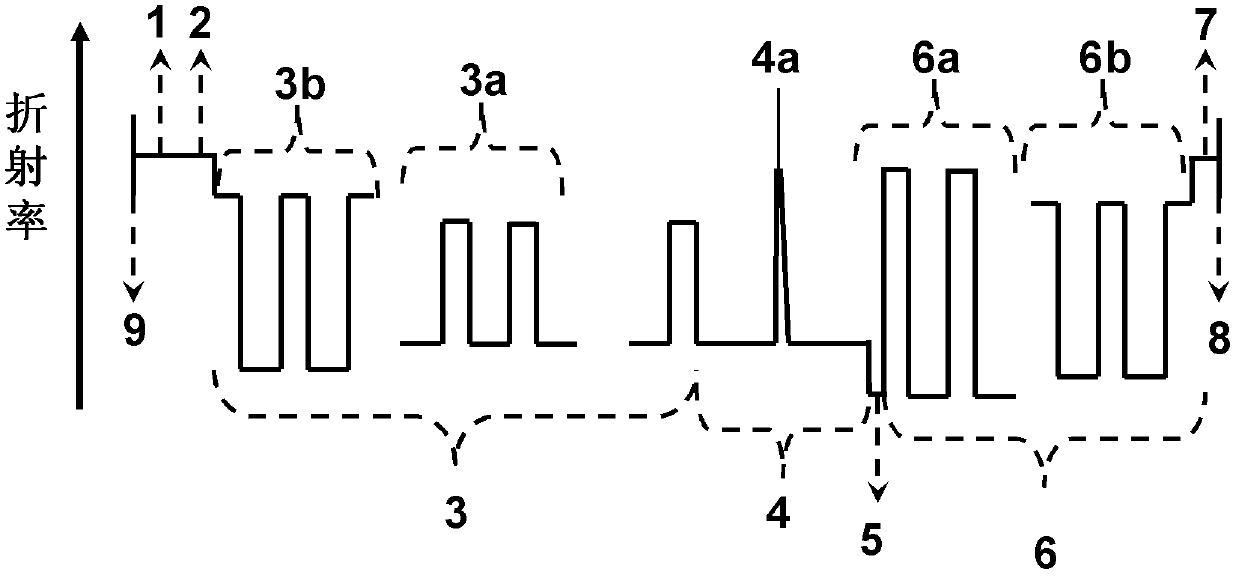

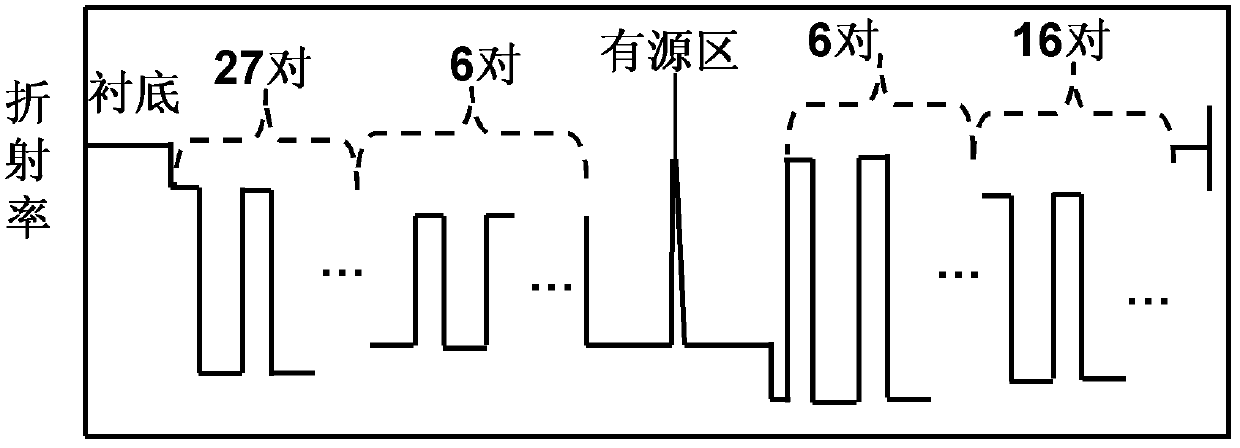

[0024] like Figure 3(a) , 3(b) , 3(c) shows the refractive index distribution, standing wave field distribution, and the relationship between output power and injection current of a vertical cavity surface emitting semiconductor laser with top-emitting asymmetric optical field distribution. In this structure, the total number of periodic material pairs of N-type segmented DBR3 is 33 pairs, and the total number of periodic material pairs of P-type segmented DBR6 is 22 pairs. The first 6 pairs of N-type DBRs and P-type DBRs close to the active area use low-refractive-index-difference and high-refractive-index-difference periodic materials, respectively. It can be seen from the distribution of the internal light field intensity of the device in Fig. 3 (b), that the distribution of the standing wave field inside the surface-emitting laser in the present invention is stronger than that of the P-type segment DBR6, that is, the light field is One side of the N-type segmented DBR3 ...

Embodiment 2

[0026] like Figure 4 As shown, compared with Embodiment 1, multiple periodic gain medium structures 4a, 4b and 4c are introduced into the active region 4 in this structure, and this structure can make the optical field obtain a large gain when it oscillates internally, thus obtaining High output power. The characteristic of this structure is that the thickness of the active region 4 is very large, and the standing wave field has multiple oscillation peaks inside the active region 4, and the gain medium is inserted at each corresponding peak position, which improves the utilization efficiency of the gain medium layer for the injected current , and the optical gain of the whole structure is greatly enhanced, thereby further increasing the optical power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com