Thin film electroluminescence device and manufacturing method thereof

An electroluminescent device and thin film technology, applied in electroluminescent light sources, electric light sources, electrical components, etc., can solve problems such as restricting the development of color TFEL display devices, and achieve the effects of low cost, improved luminous efficiency, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

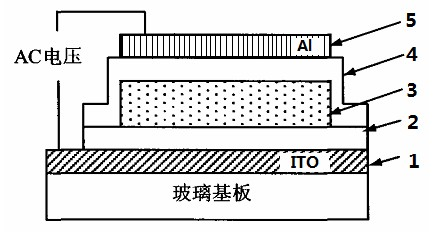

[0023] The light-emitting device includes an ITO conductive glass layer, a first insulating layer, a light-emitting layer, a second insulating layer and a metal electrode layer arranged in sequence, and the light-emitting layer is SiO2 gel-coated doped semiconductor quantum dots ZnSe:Mn / ZnS film.

[0024] The preparation of this device includes the following steps:

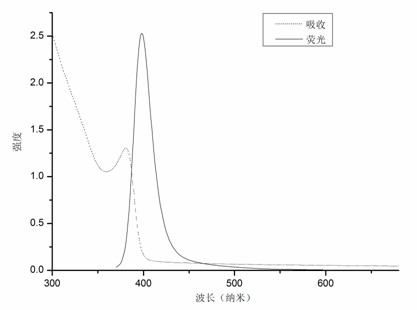

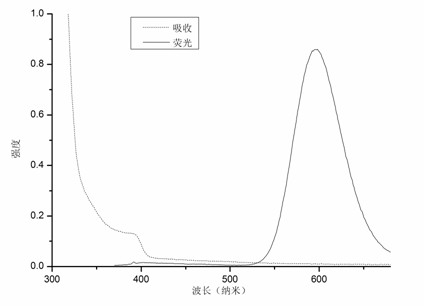

[0025] 1. Preparation of doped semiconductor quantum dots ZnSe:Mn / ZnS

[0026] ZnSe:Mn / ZnS was synthesized by growth-doping method. First, the Zn precursor ZnSt2 and ODE were stirred and degassed for 15 minutes in an Ar gas environment in a three-necked flask, and the Se precursor was injected at 270 ° C for 20 minutes, and the ZnSe quantum dots were obtained after purification and centrifugation. Take a certain amount of ZnSe quantum dots, oleylamine and ODE in a 50ml three-necked flask, and heat the degassed mixture to 120°C. Inject the MnSt2 / ODE reaction at this temperature for 5 min. After the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com