Fish collagen granular formulation and preparation method thereof

A technology of fish collagen and granules, which is used in animal protein processing and other directions to achieve the effects of rich nutrition, excellent solubility and fast sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

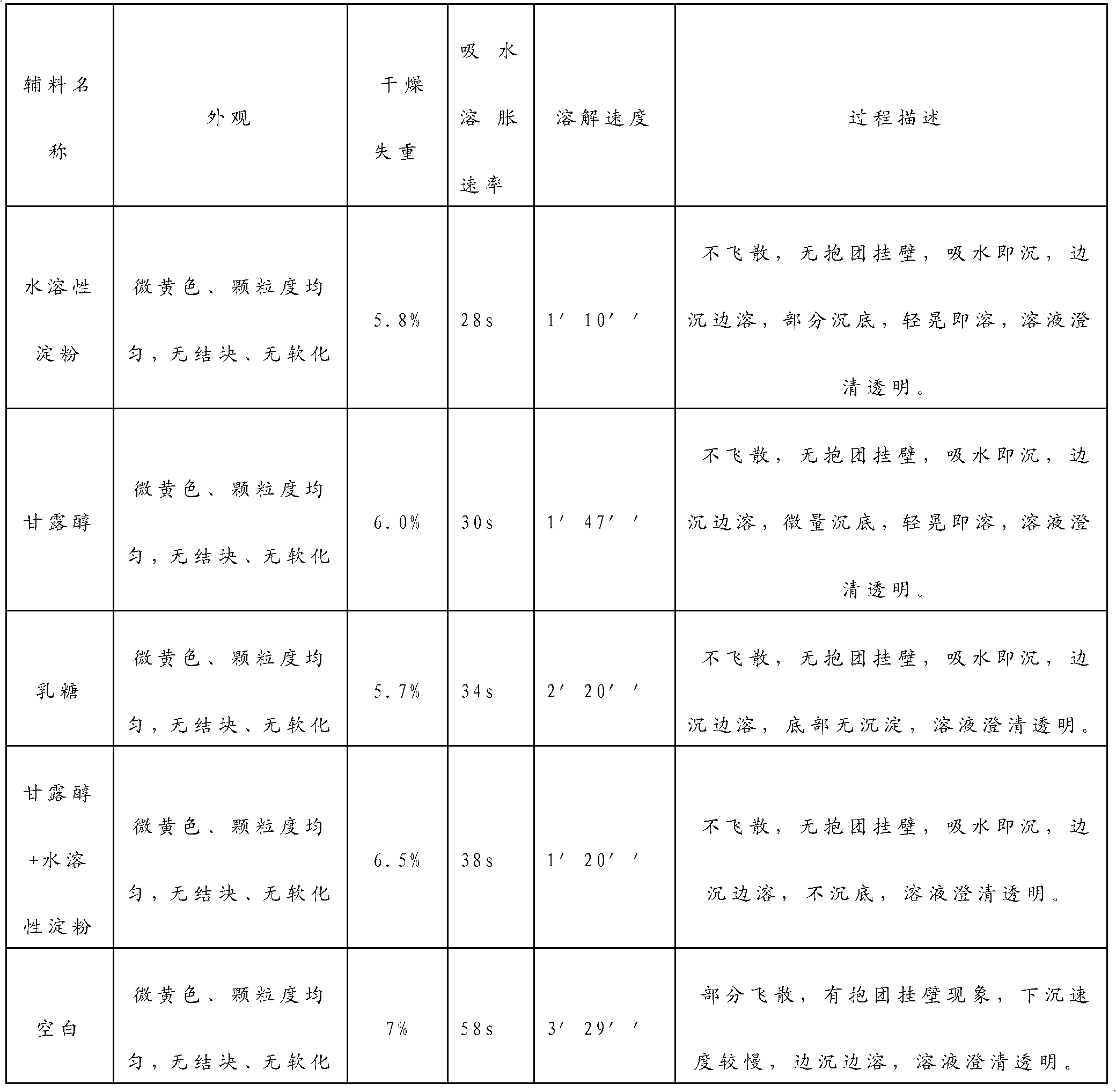

Examples

Embodiment 1

[0042] Ingredients Ratio:

[0043] Collagen Powder 100kg

[0044] Water-soluble starch 0.5kg

[0045] Using a PGL-20 spray drying granulator, add 100kg of collagen powder to the hopper as a dry powder parent, make it into a boiling state under the action of a hot air flow at 105°C, and prepare the water-soluble starch into a solution with a mass fraction of 6%. Add 10kg / h of auxiliary material solution through the atomizer. Under the action of hot air, the mist droplets are boiled and dried, and granulated, and the negative pressure in the tower is maintained at 20-30Pa by the negative pressure suction of the induced draft fan. Until the addition of the co-solvent solution is stopped and the particles reach the drying requirements. The granules are screened through 50 meshes and 80 meshes in turn to obtain collagen granules.

Embodiment 2

[0047] Ingredients Ratio:

[0048] Collagen Powder 100kg

[0049] Mannitol 0.3kg

[0050] Using a PGL-20 spray drying granulator, add 100kg of collagen powder to the hopper as a dry powder parent, make it into a boiling state under the action of 100 ℃ hot air, and prepare mannitol into a solution with a mass fraction of 10%. Add 10kg / h of auxiliary material solution through the atomizer. Under the action of hot air, the mist droplets are boiled and dried, and granulated, and the negative pressure in the tower is maintained at 20-30Pa by the negative pressure suction of the induced draft fan. Until the addition of the co-solvent solution is stopped and the particles reach the drying requirements. The granules are screened through 50 meshes and 80 meshes in turn to obtain collagen granules.

Embodiment 3

[0052] Ingredients Ratio:

[0053] Collagen 100kg

[0054] Lactose 1kg

[0055] Using a PGL-20 spray drying granulator, add 100g of collagen powder to the hopper as a dry powder parent, make it into a boiling state under the action of hot air at 95 ℃, and formulate lactose into a solution with a mass fraction of 12%. Add 10kg / h of auxiliary material solution through the atomizer. Under the action of hot air, the mist droplets are boiled and dried, and granulated, and the negative pressure in the tower is maintained at 20-30Pa by the negative pressure suction of the induced draft fan. Until the addition of the co-solvent solution is stopped and the particles reach the drying requirements. The granules are screened through 50 meshes and 80 meshes in turn to obtain collagen granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com