Method for processing Fischer-Tropsch synthesis tail gas

A Fischer-Tropsch synthesis and tail gas treatment technology, which is applied in separation methods, chemical instruments and methods, and air quality improvement, etc., can solve the problems of high energy consumption, complex process flow, and various product types, and achieves increased added value and economic benefits. optimal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

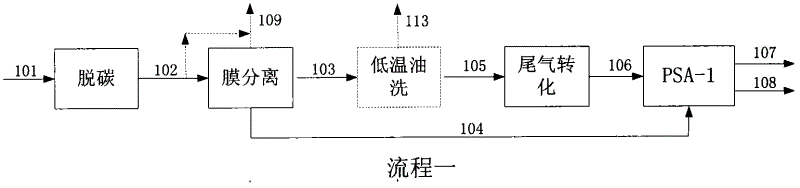

[0035] according to figure 1 The flow process one in is taken as an example, and embodiment 1 is given. The tail gas (stream 101) from the Fischer-Tropsch synthesis unit is passed through the decarburization unit, and the CO is removed by the hot potash method. 2 Components; a part of the decarbonized tail gas (stream 102) goes to the membrane separation unit to recover hydrogen, and the membrane separation unit uses two-stage membrane separation. One H 2 The gas at the / CO ratio is returned to the Fischer-Tropsch synthesis unit as recycle gas (stream 109), the primary membrane separation permeate gas goes to the secondary membrane separation, the secondary membrane separation permeate gas (stream 104) goes to the PSA unit for hydrogen production, and the non-permeate gas ( Stream 103) goes to the low-temperature oil washing unit to recover the liquefied gas component; the low-temperature oil washing unit recovers the liquefied gas component in the membrane separation non-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com