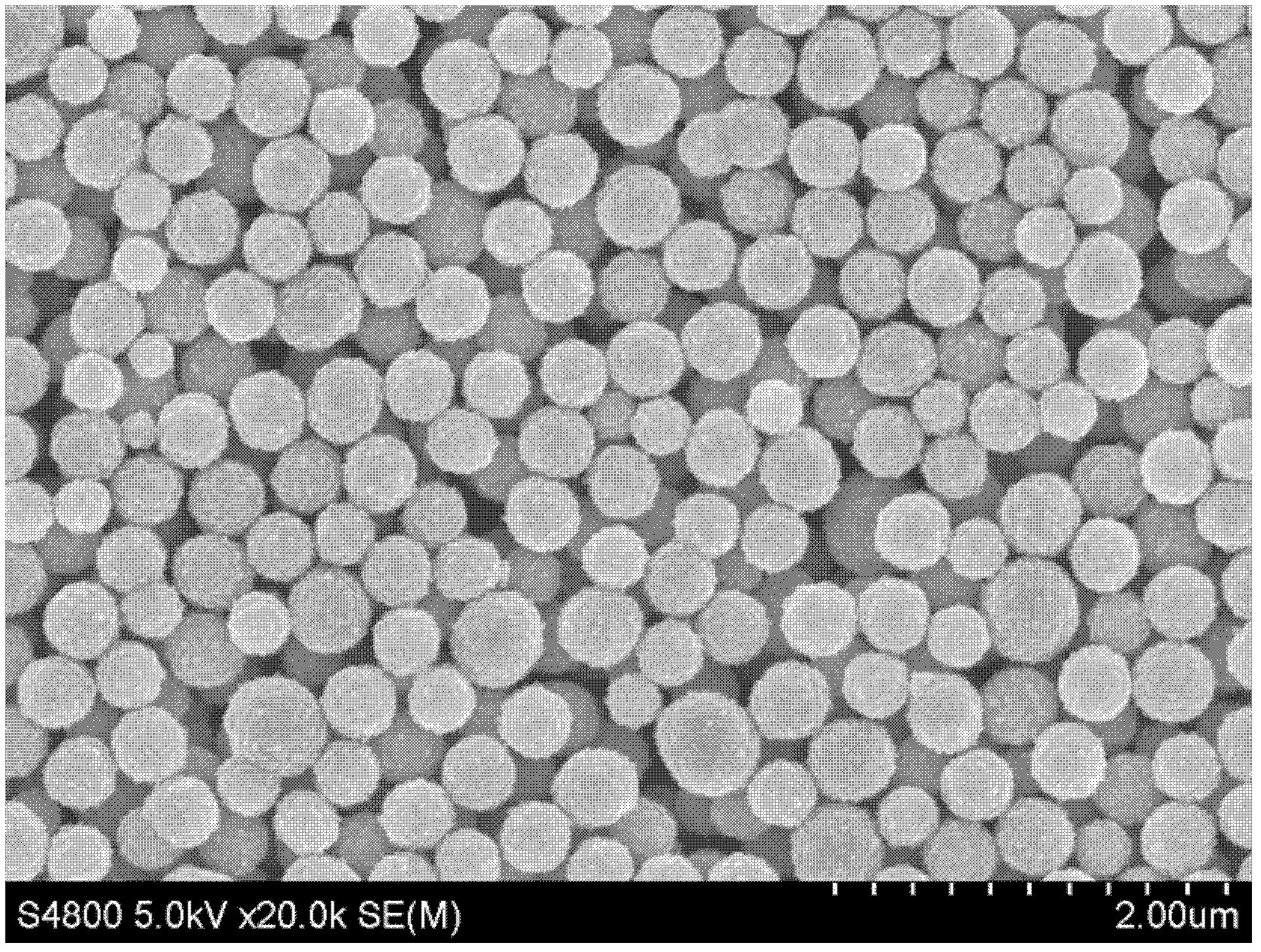

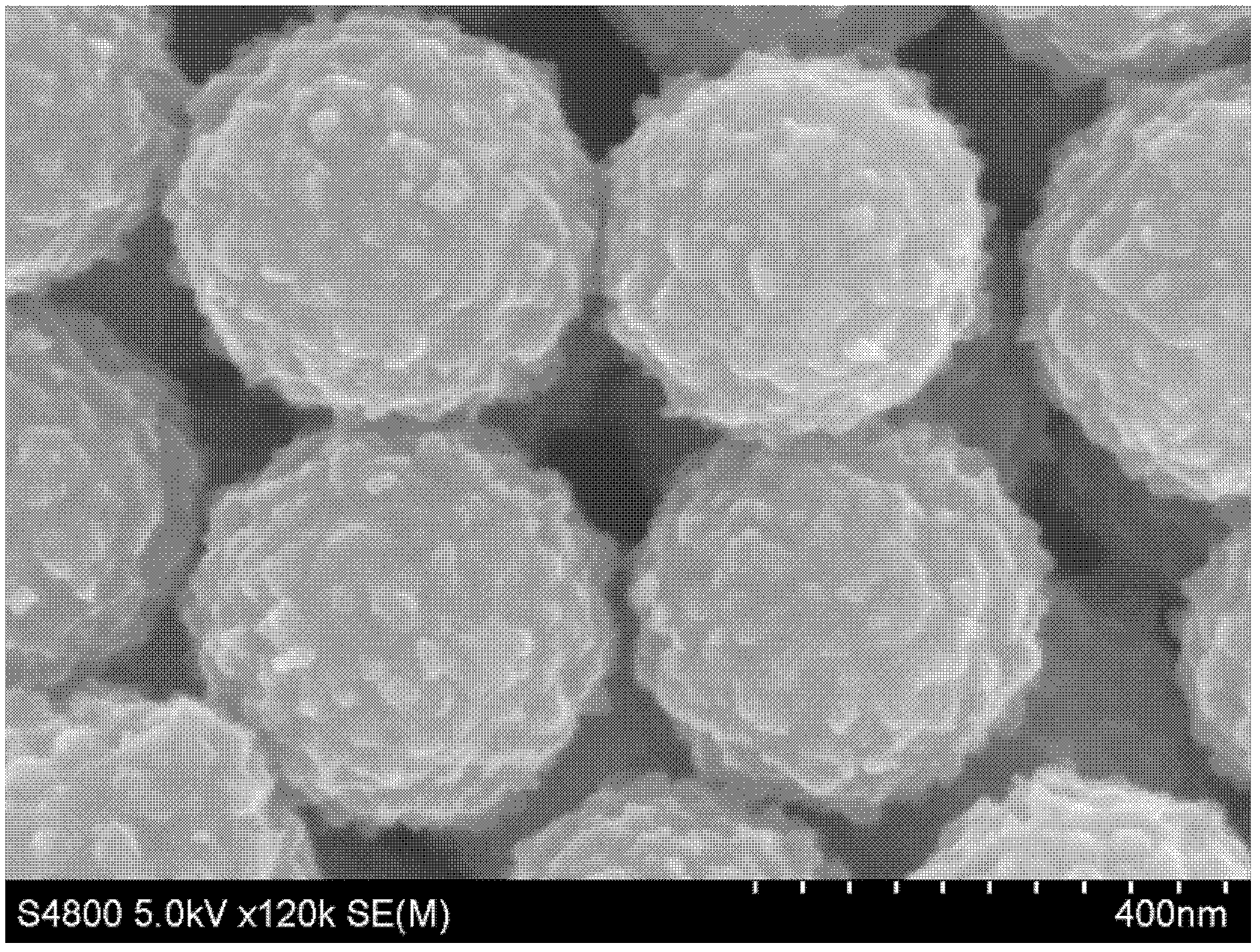

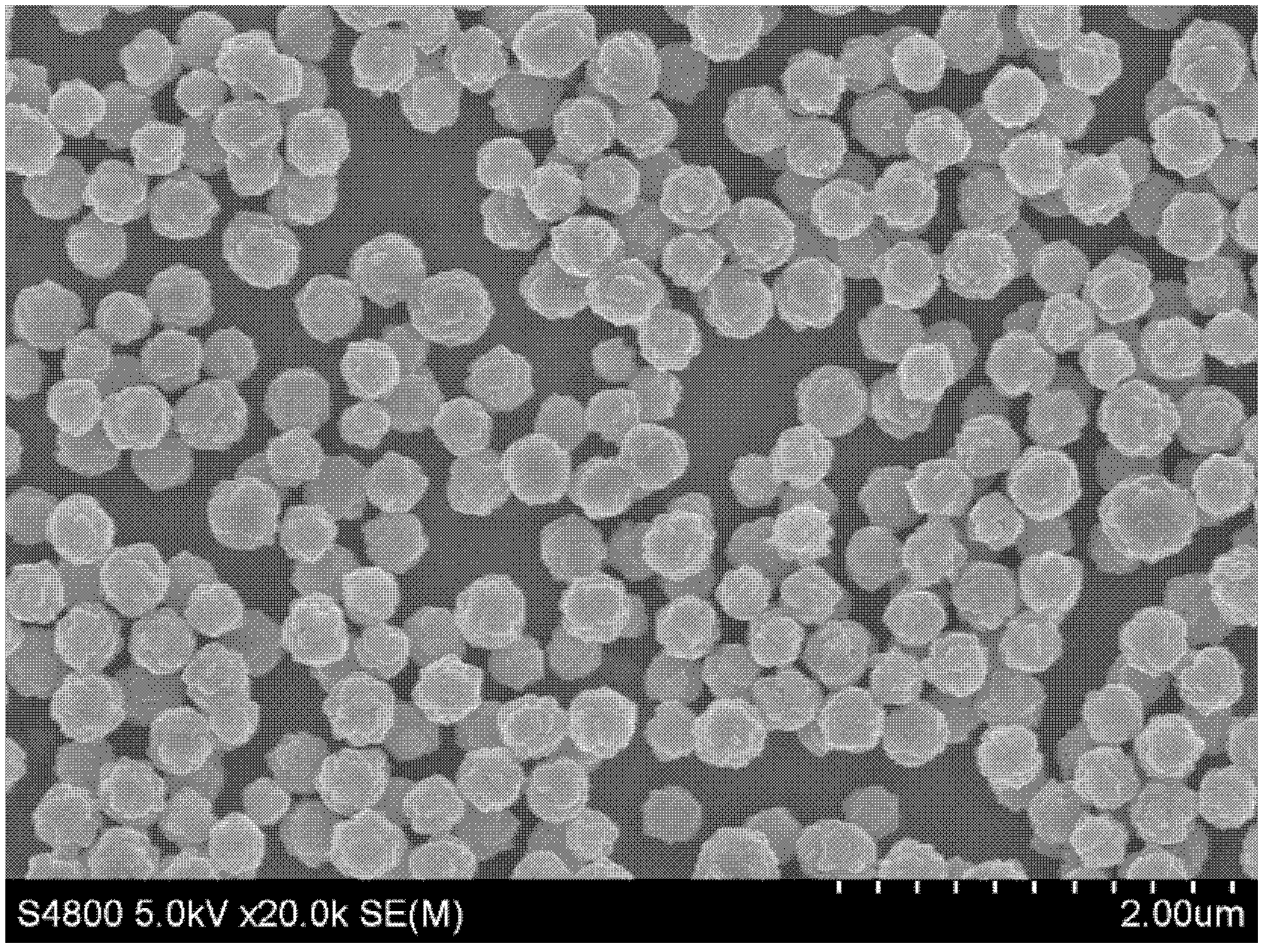

Preparation method for monodisperse vanadium pentoxide solid microspheres

A vanadium pentoxide and monodisperse technology, which is applied in the field of preparation of vanadium pentoxide solid microspheres, can solve the problems of complex heat treatment process and many added species, and achieves the effects of simple heat treatment process, simple raw materials and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment one: the preparation method of monodisperse vanadium pentoxide solid microsphere of this embodiment is carried out according to the following steps:

[0013] One, be 30% hydrogen peroxide by mass fraction: the volume ratio of distilled water=1: (1.5~4), preparation hydrogen peroxide aqueous solution; Preparation molar concentration is the methanol solution of the vanadium acetylacetonate of 0.015mol / L~0.033mol / L ;

[0014] Two, be 1: (4~8) ratio by volume ratio and take the aqueous hydrogen peroxide solution and the methanol solution of vanadium acetylacetonate prepared in step 1, join the methanol solution of vanadium acetylacetonate by hydrogen peroxide solution, stir After 1-2 hours, transfer to a reaction kettle, react at a temperature of 180-200°C for 4-24 hours, and obtain a vanadium oxide precursor;

[0015] 3. After washing the vanadium oxide precursor obtained in step 2 with ethanol, at a temperature of 60-70°C, vacuum-dry for 10-15 hours t...

specific Embodiment approach 2

[0018] Specific embodiment two: this embodiment is different from specific embodiment one: in step one, be 30% hydrogen peroxide by mass fraction: the volume ratio of distilled water=1: (2~3), prepare aqueous hydrogen peroxide solution. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, a methanol solution of vanadium acetylacetonate with a molar concentration of 0.02 mol / L-0.03 mol / L is prepared. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com