Wastewater treatment system

A wastewater treatment system and water outlet technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high moisture content of sludge, large floor area, long treatment process, etc. problems, to achieve the effect of cleaning the treatment process, improving the treatment efficiency and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

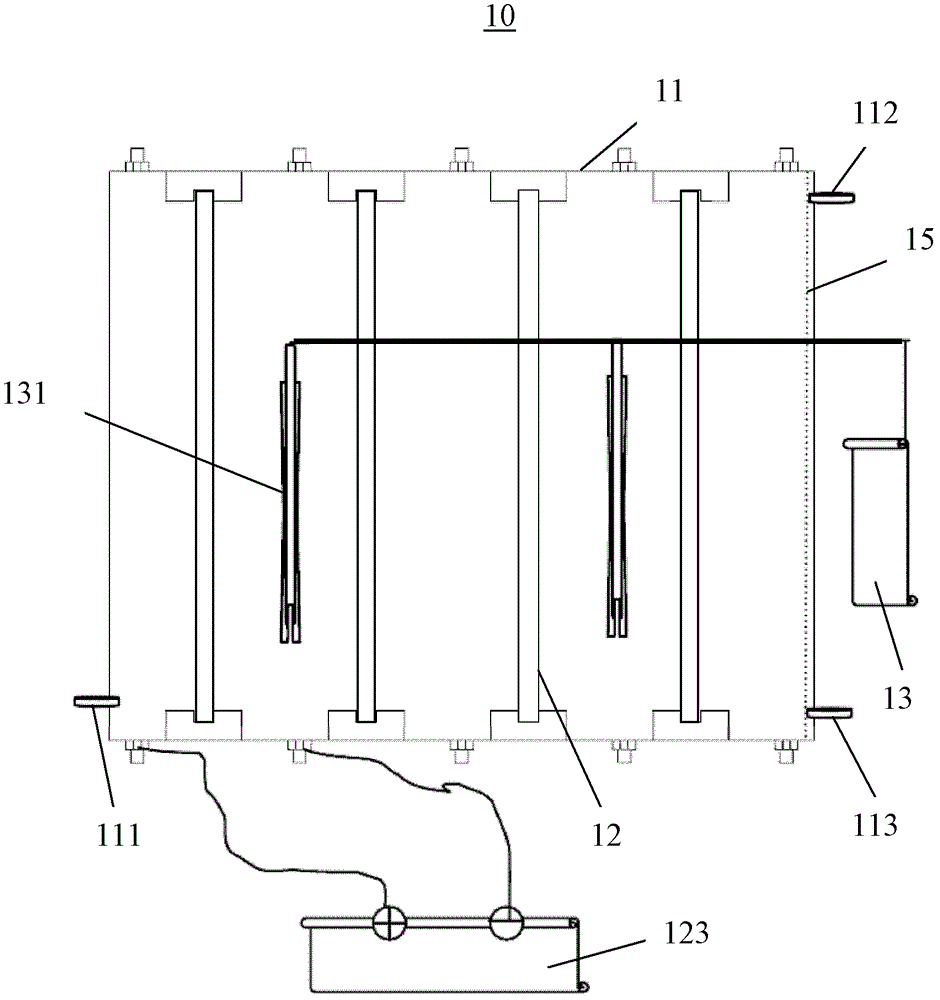

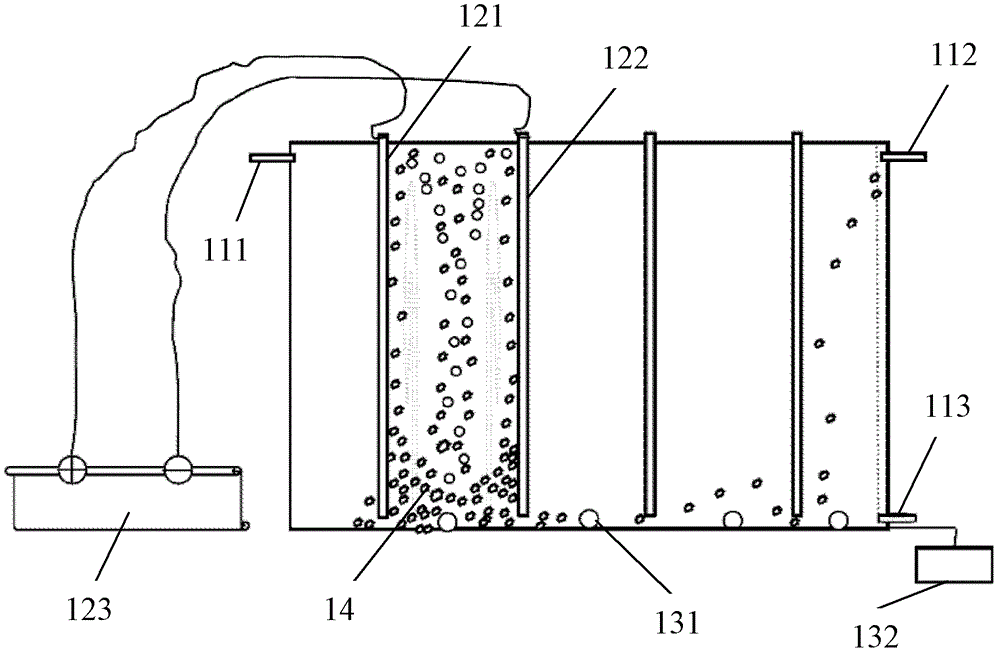

[0032] Analysis of the treatment effect of the effluent after biochemical treatment of oil refinery wastewater.

[0033] Refining wastewater is refractory wastewater. The refining process consumes a lot of water, and the water quality of the discharged wastewater is complex and highly volatile. Using the above-mentioned wastewater treatment system 10 with a treatment capacity of 60 L / h, a 30-day on-site continuous operation test was carried out on the biochemical discharge water of an oil refinery wastewater. The results show that: when the influent water quality index COD fluctuates between 80.0-360mg / L, the average value is 220mg / L; when the ammonia nitrogen concentration is around 40.0mg / L, the control reaction time is 20min, and the COD of the system effluent after the reaction is lower than 50mg / L, the average removal rate can reach 80.1%; the concentration of ammonia nitrogen in the effluent is lower than 4mg / L, and the removal rate of ammonia nitrogen reaches more than ...

Embodiment 2

[0035] Analysis of the treatment effect of printing and dyeing wastewater after biochemical treatment.

[0036] The printing and dyeing industry consumes a lot of water, the water quality is complicated, and the concentration of pollutants fluctuates greatly. Using the above-mentioned wastewater treatment system 10 with a treatment capacity of 60 L / h, a 3-week on-site continuous operation test was carried out on the discharged water after biochemical treatment of printing and dyeing wastewater. The main water quality indicators of the experimental water are: the COD fluctuation of the influent water quality index is between 80-120mg / L, and the average value is 100mg / L; the chroma is 40-80, and the average value is 60. The reaction time was controlled at 20 min during the experiment. The effluent results show that the average COD removal rate of the device can still reach 60%, the effluent COD is lower than 50mg / L, and the chroma removal rate is close to 100%; the average slud...

Embodiment 3

[0038] Analysis of the advanced treatment effect of effluent after biochemical treatment of domestic wastewater.

[0039] The production of domestic wastewater has now exceeded the discharge of industrial wastewater, becoming the main source of wastewater in my country's wastewater treatment industry, and it is also the most important potential water source in the field of reuse in the future. According to the current domestic sewage discharge standards in our country, the COD of the treated discharge water is required to be lower than the standard of 50 or 60mg / L. In the Taihu Lake Basin in Jiangsu Province, COD is required to be lower than 50, and ammonia nitrogen is lower than 5 or 8mg / L. But this standard is for some old sewage treatment plants, the COD requirement is lower than 80 or 120mg / L in the process design, and there is no standard requirement for ammonia nitrogen. Therefore, this technology is suitable for the technical transformation of old sewage treatment plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com