Method for separating and preparing high purity flavonoid glycoside compounds from actinidia valvata dunn leaves

A technology for flavonoid glycosides from kiwifruit leaves and flavonoids is applied in the field of separating and preparing high-purity flavonoid glycosides from kiwifruit leaves, which can solve the problems of decreasing sample recovery rate, polluting the environment, laborious and laborious separation by column chromatography, and the like. Achieve the effect of large preparation amount, high recovery rate and overcoming long separation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

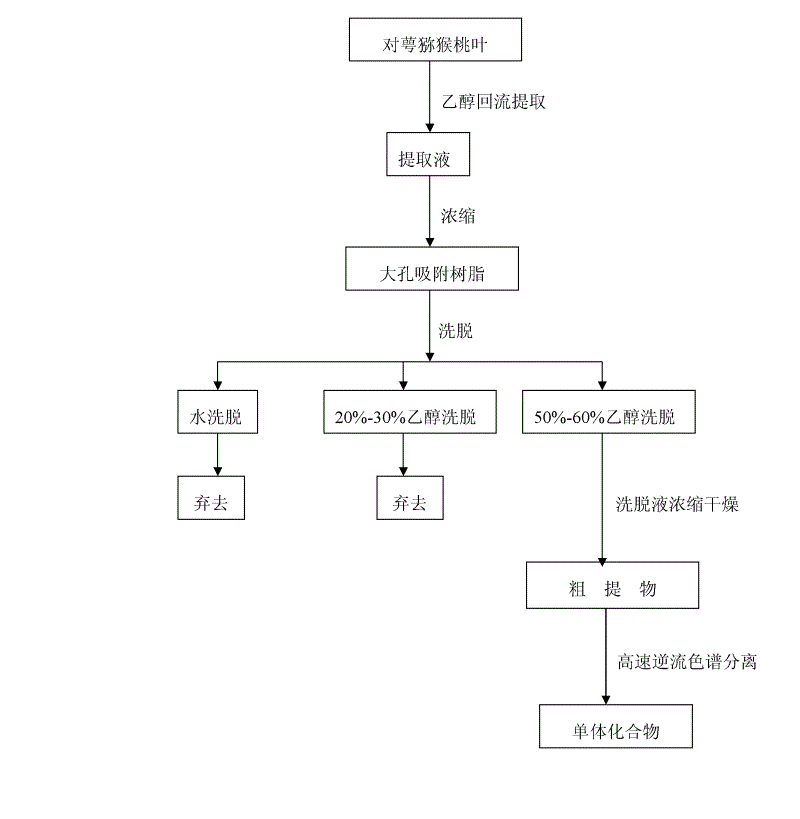

[0030]1. Medicinal material extraction: Weigh 600 g of kiwifruit leaves, reflux extraction with 6 times volume concentration of 70% ethanol twice, each time for 2 hours, filter, combine filtrates, concentrate under reduced pressure at 50°C until no alcohol smell, and obtain Concentrated extract.

[0031] 2. Preparation of crude extract: Take 1000ml of the concentrated extract, add an equal amount of water to suspend, add 500g of treated HPD-300 macroporous adsorption resin to the chromatography column, and absorb after loading 1 hour, eluted with 2500ml of water, then eluted with 3000ml of ethanol with a volume concentration of 20% and 4000ml of ethanol with a volume concentration of 60%, and collected the ethanol elution solution with a volume concentration of 60%, concentrated under reduced pressure, and dried in vacuo 28.9 g of the crude extract powder was obtained, and the extraction yield was 4.82%.

[0032] 3. Separation and purification of monomeric compounds:

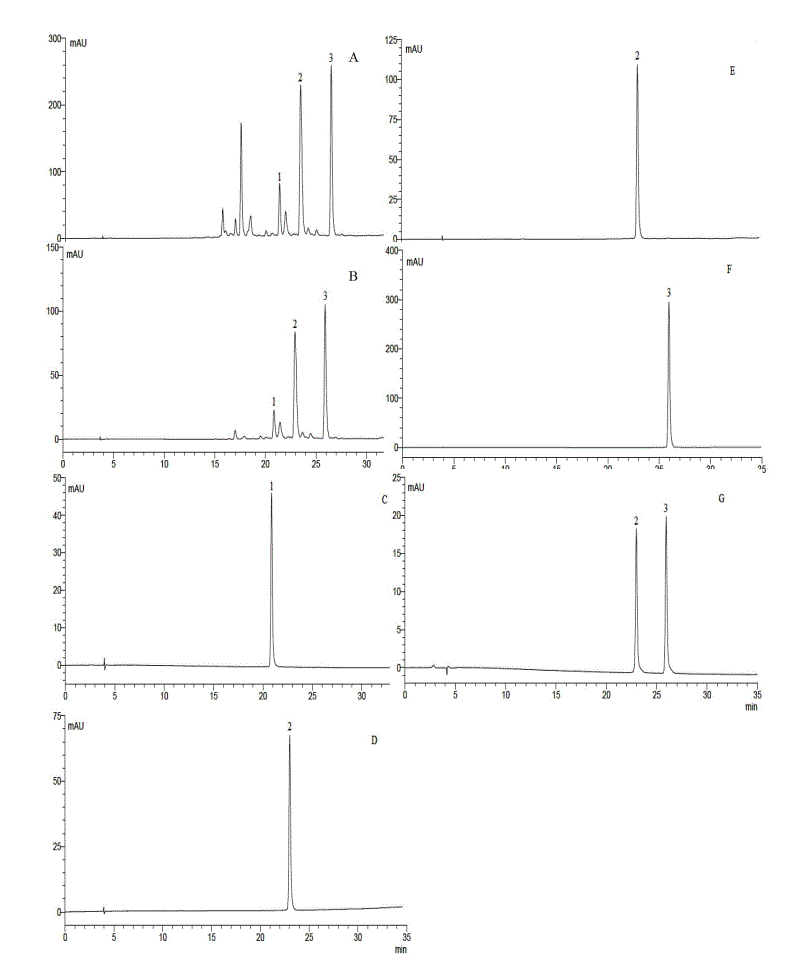

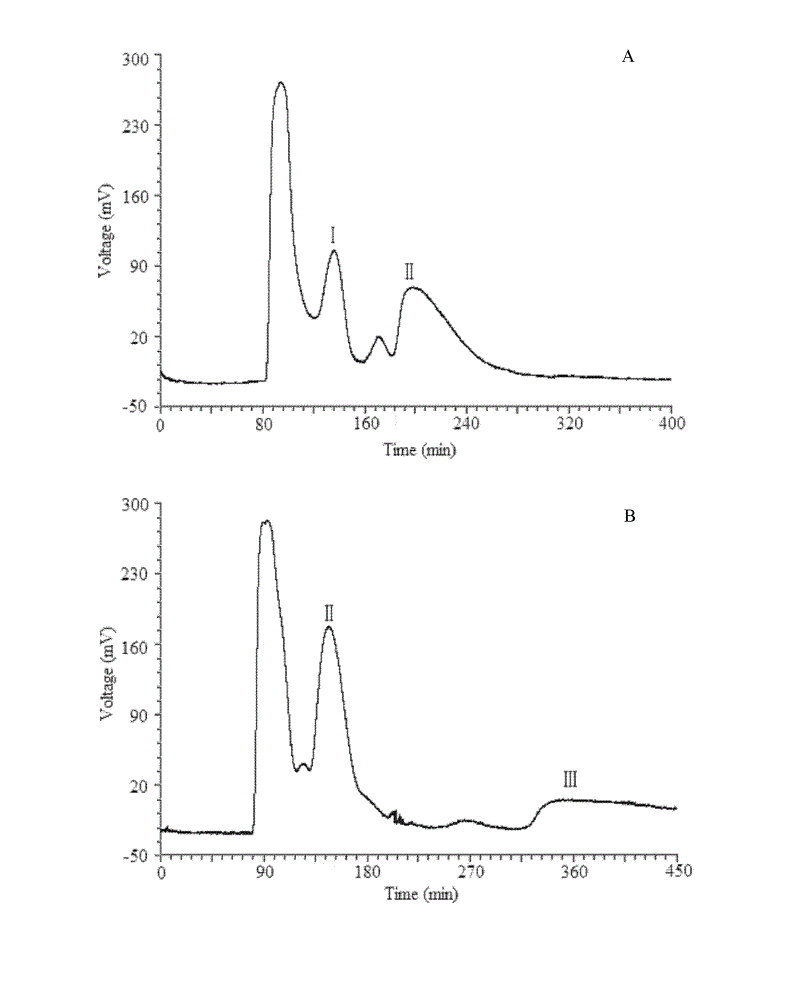

[0033...

Embodiment 2

[0044] 1. Medicinal material extraction: Weigh 600 g of kiwi fruit leaves, reflux extraction with 6 times volume concentration of 60% ethanol twice, each time for 2 hours, filter, combine filtrates, concentrate under reduced pressure at 50 ° C until no alcohol smell, to obtain Concentrated extract.

[0045] 2. Preparation of the crude extract: Take 1000ml of the concentrated extract, add an equal amount of water to suspend it, add 500g of treated DM-301 macroporous adsorption resin to the chromatographic column, after loading the sample Adsorbed for 1 hour, eluted with 2500ml of water, and then eluted with 3000ml of ethanol with a volume concentration of 20% and 4000ml of ethanol with a volume concentration of 60%, and collected the ethanol eluting solution with a volume concentration of 60%, concentrated under reduced pressure, and vacuumed After drying, 27.5 g of the crude extract powder was obtained, and the extraction yield was 4.58%.

[0046] 3. The methods and steps of ...

Embodiment 3

[0048] 1. Medicinal material extraction: Weigh 600 g of kiwifruit leaves, reflux extraction with 6 times the volume concentration of 65% ethanol twice, each time for 2 hours, filter, combine the filtrates, concentrate under reduced pressure at 50 ° C until there is no alcohol smell, and obtain Concentrate the extract.

[0049] 2. Preparation of the crude extract: Take 1000ml of the concentrated extract, add an equal amount of water to suspend, add 500g of treated HPD-300 macroporous adsorption resin to the chromatography column, after the sample is loaded Adsorbed for 1 hour, eluted with 3000ml of water, then eluted with 3000ml of ethanol with a volume concentration of 20% and 4500ml of ethanol with a volume concentration of 50%, and collected the ethanol elution solution with a volume concentration of 60%, concentrated under reduced pressure, and vacuumed Dry to obtain 30.2 g of crude extract powder, and the extraction yield is 5.03%.

[0050] 3. The methods and steps of sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com