Hydrogel contact lens material and preparation method thereof

A contact lens and hydrogel technology, applied in glasses/goggles, instruments, optics, etc., can solve problems such as tear elution, achieve good stability, excellent dehydration resistance, and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 (comparative example)

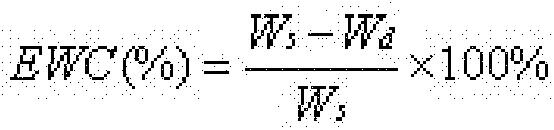

[0029] 2 g of β-hydroxyethyl methacrylate (HEMA), 0.01 g of ethylene glycol dimethacrylate (EGDMA), 0.01 g of initiator alkyl aryl ketone Darocur-1173, magnetically stir, mix well, and inject into the mold Among them, it is cured by ultraviolet light, demolded, soaked in water and washed, and placed in saline to obtain a hydrogel contact lens. The material is optically transparent, with a water content of 36%, a Young's modulus of 1.4 MPa, a water contact angle of 65 degrees, and a relative dehydration percentage (RPD5) of 40% at 5 minutes.

Embodiment 2

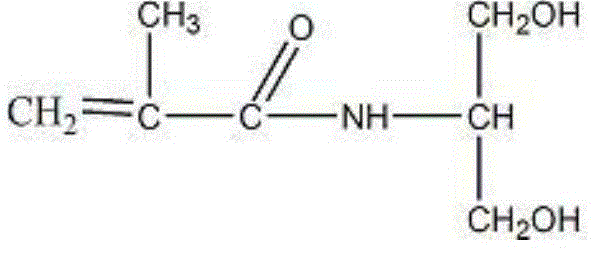

[0031] 1.9 g β-hydroxyethyl methacrylate (HEMA) and 0.1 g N-(1,3-dihydroxy-2-propyl)methacrylamide, 0.01 g ethylene glycol dimethacrylate (EGDMA) , 0.01g initiator Darocur-1173, magnetically stirred, mixed uniformly, poured into the mold, cured by ultraviolet light, demolded, soaked in water and washed, placed in saline to obtain hydrogel contact lenses. The material is optically transparent, with a water content of 42%, a Young's modulus of 1.2 MPa, a water contact angle of 55 degrees, and a relative dehydration percentage (RPD5) of 33% in the 5th minute.

Embodiment 3

[0033] 1.8 g of beta-hydroxyethyl methacrylate (HEMA) and 0.2 g of N-(1,3-dihydroxy-2-propyl)methacrylamide, 0.01 g of ethylene glycol dimethacrylate (EGDMA) , 0.01g initiator Darocur-1173, magnetically stirred, mixed evenly, poured into the mold, cured with ultraviolet light, demolded, soaked in water and washed, placed in saline to obtain hydrogel contact lenses, water content: 45% , Young's modulus: 1.2MPa, water contact angle of 50 degrees, RPD5 of 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com