Thermal stabilization type ponceau 2R intercalation hydrotalcite dye and preparation method thereof

A thermally stable and hydrotalcite technology, applied in the direction of organic dyes, can solve problems such as complex preparation methods, and achieve the effects of simple process, good thermal stability, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step A: Take MgCl 2 ·6H 2 O (13.55g, 0.066mol), AlCl 3 ·6H 2 O (8.04g, 0.033mol) was dissolved in 200ml to remove CO 2 of deionized water in a 250ml three-necked bottle. Another 20.96ml of concentrated ammonia water with a concentration of 25-28wt% was dissolved in 83.84ml of deionized water. in N 2 Slowly drip the diluted ammonia solution into the mixed salt solution under protection, stir for 10 minutes, and let stand for 45 minutes. The suspension was filtered and washed until pH = 8-9, and the obtained sol was peptized at 80° C. for 24 hours, and dried to obtain a hydrotalcite-like precursor.

[0039] Step B: Weigh Ponceau 2R (1.92g, 0.004mol) according to the ratio of Ponceau 2R to the hydrotalcite precursor molar ratio of 2, dissolve in 100ml to remove CO 2 of deionized water.

[0040] Step C: Mix 0.002 mol of the hydrotalcite-like precursor in Step A and the Ponceau 2R solution in Step B in an airtight container, stir and react at 70°C for 48 hours, filte...

Embodiment 2

[0045] Step A: Take MgCl 2 ·6H 2 O (15.23g, 0.075mol), AlCl 3 ·6H 2 O (6.03g, 0.025mol) was dissolved in 200ml to remove CO 2 of deionized water in a 250ml three-necked bottle. Another 20.21ml of concentrated ammonia water was dissolved in 80.84ml of deionized water. in N 2 Slowly drip the diluted ammonia solution into the mixed salt solution under protection, stir for 15 minutes, and let stand for 45 minutes. The suspension was filtered and washed until pH = 8-9, and the obtained sol was peptized at 80° C. for 24 hours, and dried to obtain a hydrotalcite-like precursor.

[0046] Step B: Same as Example 1.

[0047] Step C: Mix 0.002 mol of hydrotalcite-like precursor and Ponceau 2R solution in an airtight container, stir and react at 70°C for 36 hours, filter and wash until the pH value is about 7, and dry at 70°C for 18 hours to obtain Ponceau Chunhong 2R anion intercalation hydrotalcite-like material.

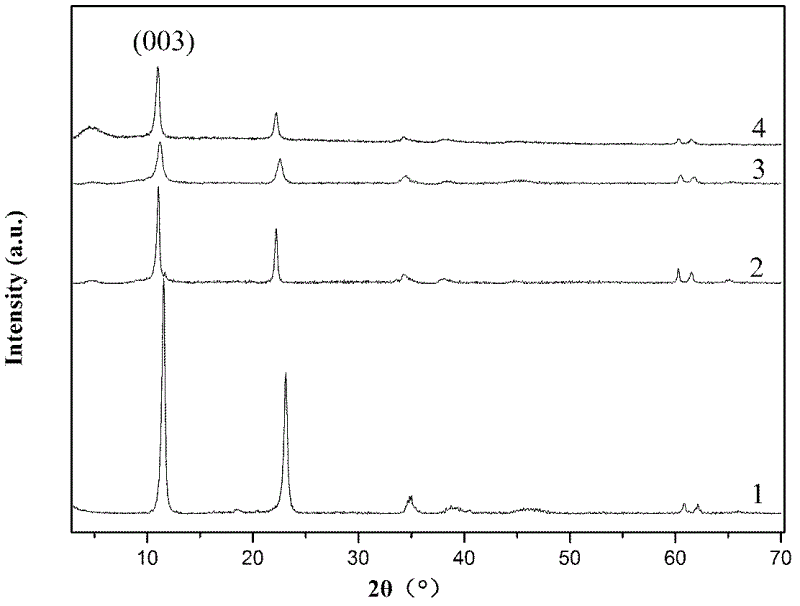

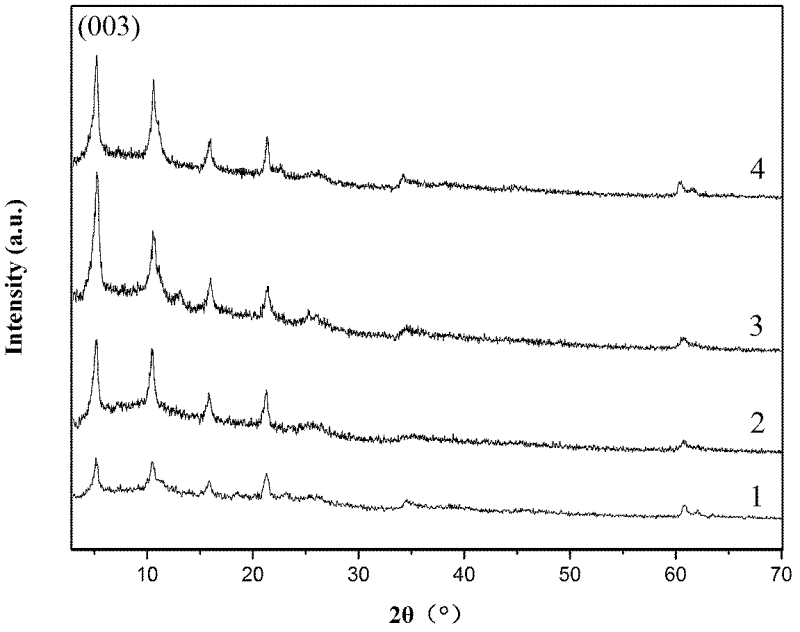

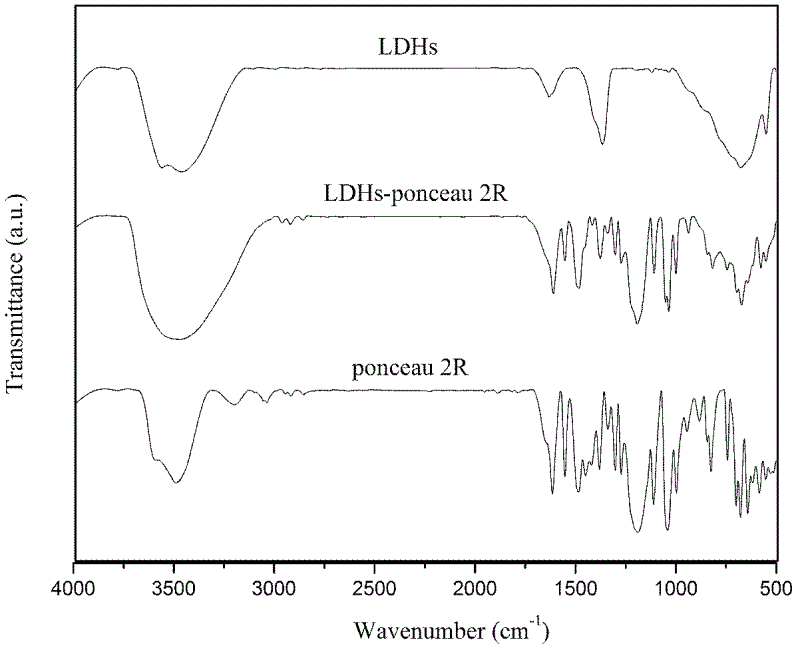

[0048] Mg prepared in step A 2+ / Al 3+ XRD of the precursor o...

Embodiment 3

[0050] Step A: Take MgCl 2 ·6H 2 O (16.26g, 0.08mol), AlCl 3 ·6H 2 O (4.82g, 0.02mol) was dissolved in 200ml to remove CO 2 of deionized water in a 250ml three-necked bottle. Another 19.75ml of concentrated ammonia water was dissolved in 79.00ml of deionized water. in N 2 Slowly drip the diluted ammonia solution into the mixed salt solution under protection, stir for 10 minutes, and let stand for 60 minutes. The suspension was filtered and washed until pH = 8-9, and the obtained sol was peptized at 80° C. for 24 hours, and dried to obtain a hydrotalcite-like precursor.

[0051] Step B: Same as Example 1.

[0052] Step C: Mix 0.002 mol of hydrotalcite-like precursor and Ponceau 2R solution in an airtight container, stir and react at 70°C for 96 hours, filter and wash until the pH value is about 7, and dry at 65°C for 24 hours to obtain Ponceau Chunhong 2R anion intercalation hydrotalcite-like material.

[0053] Mg prepared in step A 2+ / Al 3+ XRD of the precursor of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com