Room-temperature type power insulator anti-fouling flashover paint, preparation method thereof and power insulator

A technology of anti-fouling flashover coatings and insulators, applied in the field of coatings, can solve the problems of decreased migration speed of coating hydrophobicity and inability to eradicate them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix 30 parts of block resin (produced by Shenzhen Taike Technology Co., Ltd., a typical resin with hydrophobic migration properties) and 70 parts of silicone acrylic resin, add an appropriate amount of butyl acetate to adjust the concentration of the mixture, Slowly stir and blend in a closed container for 5 hours, take out the product, and add 0.5 part of leveling agent to obtain a room temperature type anti-pollution flashover hard coating for electric power external insulation.

[0033] When in use, take out 100 parts of antifouling flash hard paint, add 0.1 part of zirconium isooctanoate, 0.1 part of dibutyltin dilaurate, 1 part of ethyl orthosilicate, stir well, adjust the viscosity with butyl acetate, Then it is used for spraying or brushing on the lower surface of the insulating part of the insulator, and the thickness of the coating is 0.01mm.

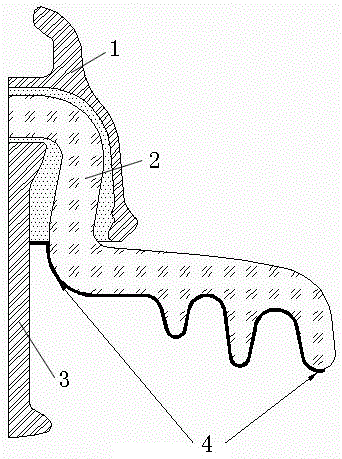

[0034] like figure 1 As shown, it is a cross-sectional view of the right half of the outer surface of an axisymmetric...

Embodiment 2

[0036] Mix 50 parts of block resin (Shenzhen Taike Technology Co., Ltd.) with 50 parts of silicone acrylic resin, add an appropriate amount of solvent to adjust the concentration of the mixture, stir and blend slowly in a closed container at room temperature for 7 hours, take out the product, add leveling 2 parts to obtain room temperature type electric power external insulation anti-pollution flashover hard coating.

[0037] When using, take out 100 parts of antifouling flash hard paint, add 1 part of zirconium isooctanoate, 1 part of dibutyltin dilaurate, N-(ethylaminoethyl)-3-aminopropylmethyl dimethoxy 1 part of silane, 7 parts of tetraethyl orthosilicate, stir evenly, adjust the viscosity with butyl acetate, and then spray or brush on the lower surface of the insulating part of the insulator, and the coating thickness is 0.02mm.

Embodiment 3

[0039] Mix 70 parts of block resin (Shenzhen Taike Technology Co., Ltd.) with 30 parts of silicone acrylic resin, add an appropriate amount of solvent to adjust the concentration of the mixture, stir and blend slowly in a closed container at room temperature for 7 hours, take out the product, add leveling The antifouling flashover hard coating for room temperature electric power external insulation was obtained by adding 5 parts of the agent.

[0040] When using, take out 100 parts of antifouling flash hard paint, add 2 parts of zirconium isooctanoate, 2 parts of dibutyltin dilaurate, N-(ethylaminoethyl)-3-aminopropylmethyl dimethoxy 2 parts of silane and 10 parts of tetraethyl orthosilicate are stirred evenly, and the viscosity is adjusted with butyl acetate, and then sprayed or brushed on the lower surface of the insulating part of the insulator, and the coating thickness is 0.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com