High-efficiency microalgae culturing device based on plant bionics

A technology of microalgae cultivation and bionics, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical equipment and methods, etc. High utilization efficiency, improved light energy utilization efficiency, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

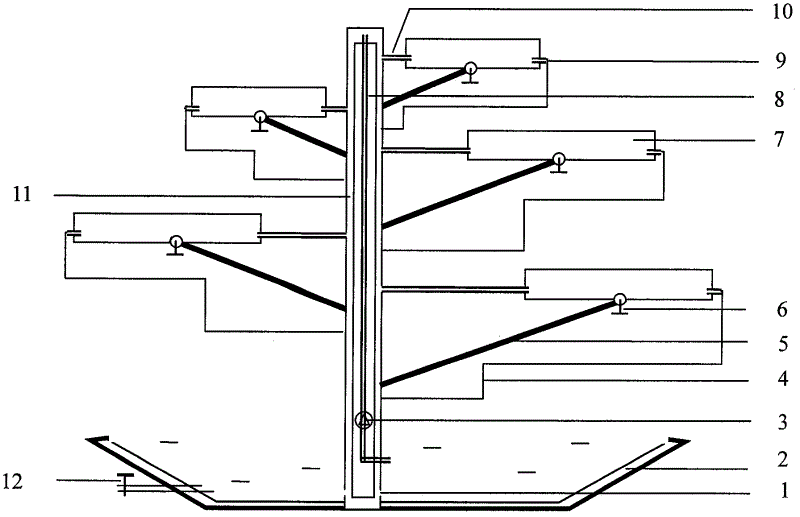

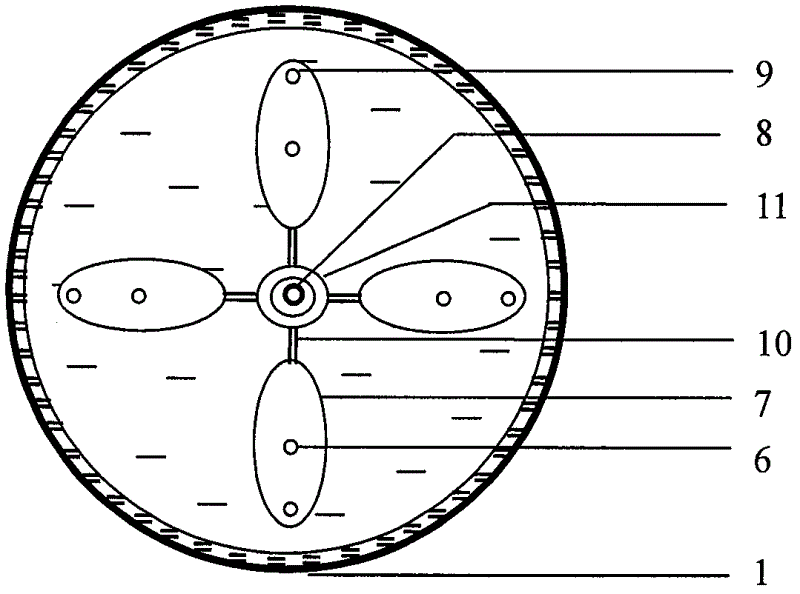

[0020] A high-efficiency microalgae cultivation device based on plant bionics, including: a root reactor (2), which is in the shape of an inverted "trapezoid", the bottom of the pool is a brick-concrete structure, the pool wall is made of plexiglass, and the diameter of the bottom is 4m, high 50cm, pond wall thickness 0.5cm, root reactor provides growth environment and nutrition for algal cells; stem reactor (11) is made of plexiglass, and the shape of the device is circular, and the outer diameter of the ring is 40cm, and the inner diameter of the ring is 40cm. It is 30cm, the ring height is 2m, and the ring wall thickness is 1cm. The stem reactor is a place for mixing algae liquid; the leaf reactor (7) is a place for photosynthesis of algae cells. The diameter is 1m, from the top of the stem reactor to the bottom, it is spirally fixed on the fixed bracket (5) at equal intervals, the interval is 25cm, and the included angle is 60 degrees. The leaf reactor (7) is made of plexig...

Embodiment 2

[0022] A high-efficiency microalgae cultivation device based on plant bionics. A set of angle adjustment device is installed at the junction of fixed support (5) and leaf reactor (7), and all the other parts are identical with above-mentioned example. In the afternoon, the direction of illumination changes, and the angle adjusting device (6) is adjusted, and the upper surface of the leaf reactor is adjusted to a suitable angle according to the sun position until harvesting. The remaining steps are the same as the above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com