Preparation method of pyroracemic acid-3-nickle pyridinecarbonylhydrazone (II) coordination compound/multi-wall carbon nanotube modified glassy carbon electrode

A technology of nickel pyridinecarboylhydrazone and multi-walled carbon nanotubes, which is applied in the field of electrochemistry, can solve the problems such as no substitutes have been found, and achieve the effects of simple production method, good electrocatalytic oxidation activity, and high electrocatalytic oxidation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0013] (1) Polish the glassy carbon electrode to a mirror surface on metallographic sandpaper, then place it in double-distilled water and absolute ethanol for 3 minutes, and then dry it in an infrared drying oven;

[0014] (2) Weigh 45.000mg of pyruvate-3-pyridineformylhydrazone nickel (II) complex and 1.000mg of multi-walled carbon nanotubes (previously use 98% nitric acid to heat and reflux for 4 hours) in a 25mL beaker , then accurately measure 10.0mL dimethyl sulfoxide with a pipette and add it, and then ultrasonically vibrate for 6 minutes;

[0015] (3) Use a micro sampler to extract 10 μL of the solution obtained in step (2), drop-coat it on the surface of the glassy carbon electrode dried in step (1), and dry it in an infrared drying oven to obtain the 3-pyridineformylhydrazone Schiff base Nickel(II) complexes / carbon nanotubes modified glassy carbon electrodes.

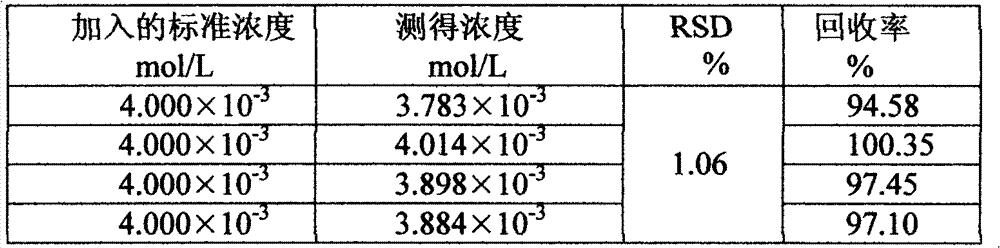

[0016] Make commercially available ham sausage into mud, accurately weigh 25.0g into a 100mL beaker, add 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com