Method for preparing high energy density capacitor

A technology with high energy density and capacitors, applied in capacitors, fixed capacitors, circuits, etc., can solve the problems of inability to store energy and small size of nanocapacitor arrays, and achieve the effects of easy operation, high energy density, and reasonable and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

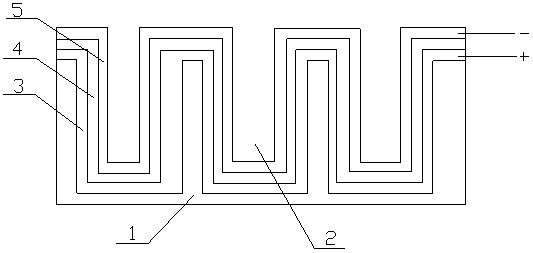

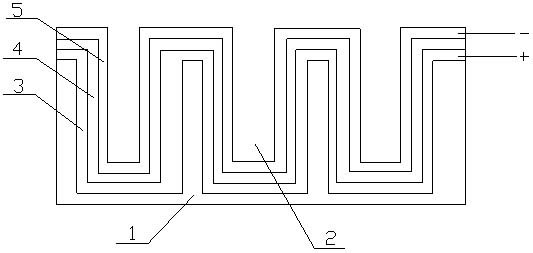

[0035] exist figure 1In the process, the flexible porous polycarbonate matrix material 1 is subjected to surface plasma treatment, the porous polycarbonate matrix material treated by surface plasma is placed in the cavity of the vacuum deposition equipment, and the vacuum deposition method is used to deposit the polycarbonate pores ( figure 1 2) Preparation of metal nano-films such as Au ( figure 1 Middle 3) as an electrode of the capacitor.

[0036] The porous polycarbonate matrix material deposited with the Au electrode film is placed in the chamber of the atomic film deposition equipment, and the atomic deposition method is used to deposit Al on the surface of the Au film. 2 o 3 and other dielectric nanofilms ( figure 1 Medium 4).

[0037] Use the atomic deposition method to continue to deposit TiN and other metal nano-films on the surface of dielectric nano-films as electrodes ( figure 1 5) to obtain a metal-insulator-metal nanocapacitor structure in the porous nanost...

Embodiment 2

[0045] Such as figure 1 , the capacitor dielectric nano-film is HfO 2 .

[0046] The fabrication process of the nanocapacitor is similar to Embodiment 1. A porous nanostructure-based Au-HfO 2 - High energy density nanocapacitor structure of TiN.

Embodiment 3

[0048] Such as figure 1 , the capacitor dielectric nano-film is HfO 2 .

[0049] The two electrode materials of the nanocapacitor are Al and TiN respectively, and the preparation process is similar to the first embodiment. Thus, a porous nanostructure based Al-HfO 2 - High energy density nanocapacitor structure of TiN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com