Method for treating seaculture wastewater by marine polysaccharide dual-component flocculant

A technology of mariculture and marine polysaccharides, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as deterioration, frequent disease occurrence, unsafety, etc., achieve the effects of reducing harmful microorganisms, protecting food safety, and wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 The method of the present invention is used to treat the prawn mariculture wastewater in the following steps.

[0016] 1. Preparation of chitosan components: In 1L of deionized water, add 10ml of 1% glacial acetic acid to form a dilute acetic acid solution, then add 1g of chitosan extracted from shrimp, stir at 450rpm for 30min, After standing for 1 hour, filter and take the filtrate to obtain a 0.1% chitosan solution;

[0017] 2. Preparation of sodium alginate components: add 10g of sodium alginate extracted from algae to 1L of deionized water, stir at 450rpm for 30min to completely dissolve it to obtain a 1% sodium alginate solution;

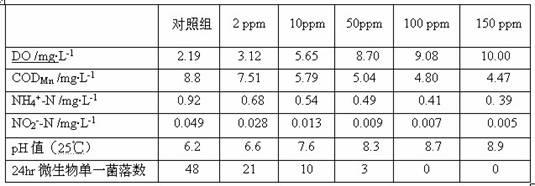

[0018] 3. Marine polysaccharide two-component flocculant is used for wastewater treatment: the prepared chitosan component is put into the marine aquaculture wastewater at a concentration of 15ppm, and stirred at 450rpm for 10min to make it completely mixed and uniform. Then the sodium alginate component was put into the marine aqu...

Embodiment 2

[0019] Example 2 The method of the present invention is used to treat the scallop mariculture wastewater in the mariculture farm according to the following steps.

[0020] 1. Preparation of chitosan components: In 1L of deionized water, add 10ml of 1% glacial acetic acid to form a dilute acetic acid solution, then add 10g of chitosan extracted from crabs, stir for 50min at 350rpm, After standing for 1.2 hours, filter and take the filtrate to obtain 1% chitosan solution;

[0021] 2. Preparation of sodium alginate components: add 1g of sodium alginate extracted from algae to 1L of deionized water, stir at 400rpm for 35min to completely dissolve it to obtain a 0.1% sodium alginate solution;

[0022] 3. Marine polysaccharide two-component flocculant is used for wastewater treatment: the prepared chitosan component is put into marine aquaculture wastewater at a concentration of 10ppm, and stirred at 500rpm for 8min to make it completely mixed and uniform. Then the sodium alginate compon...

Embodiment 3

[0023] Example 3 The method of the invention is used to treat the wastewater from shrimp mariculture farms in the following steps.

[0024] 1. Preparation of chitosan components: In 1L of deionized water, add 10ml of 1% glacial acetic acid to form a dilute acetic acid solution, then add 80g of chitosan extracted from shrimps, and stir for 35min at 400rpm. After standing for 1.4 hours, filter and take the filtrate to obtain an 8% chitosan solution;

[0025] 2. Preparation of sodium alginate components: add 100g of sodium alginate extracted from algae to 1L of deionized water, stir at 500rpm for 25min to completely dissolve it to obtain a 10% sodium alginate solution;

[0026] 3. Marine polysaccharide two-component flocculant is used for wastewater treatment: the prepared chitosan component is put into marine aquaculture wastewater at a concentration of 50ppm, and stirred at 450rpm for 5min to make it completely mixed and uniform. Then the sodium alginate component was put into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com