Pumice concrete with the function of electromagnetic wave absorption, and preparation method thereof

A concrete and electromagnetic wave technology, which is applied in the field of building absorbing materials, can solve the problems of cement-based materials such as adverse effects on performance, high price, and high quality, and achieve the effects of good durability, low finished product price, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, the weight ratio of cement, water, sand, coarse aggregate, and wave absorbing agent is 1:0.43:1.60:0.98:0.01:0.015

[0037] Prepare as follows:

[0038] (1) Use carbon black as a wave absorbing agent, and disperse the wave absorbing agent in ordinary Portland cement;

[0039] (2) Add the sand to the mixer and stir together with cement and wave absorbing agent;

[0040] (3) After the pumice aggregate is saturated with water, add it to the mixer and stir together;

[0041] (4) add water separately;

[0042] (5) Molding: inject the well-mixed material into the mold and form it;

[0043] (6) Demoulding: Demoulding becomes the wave-absorbing pumice concrete product in the final shape.

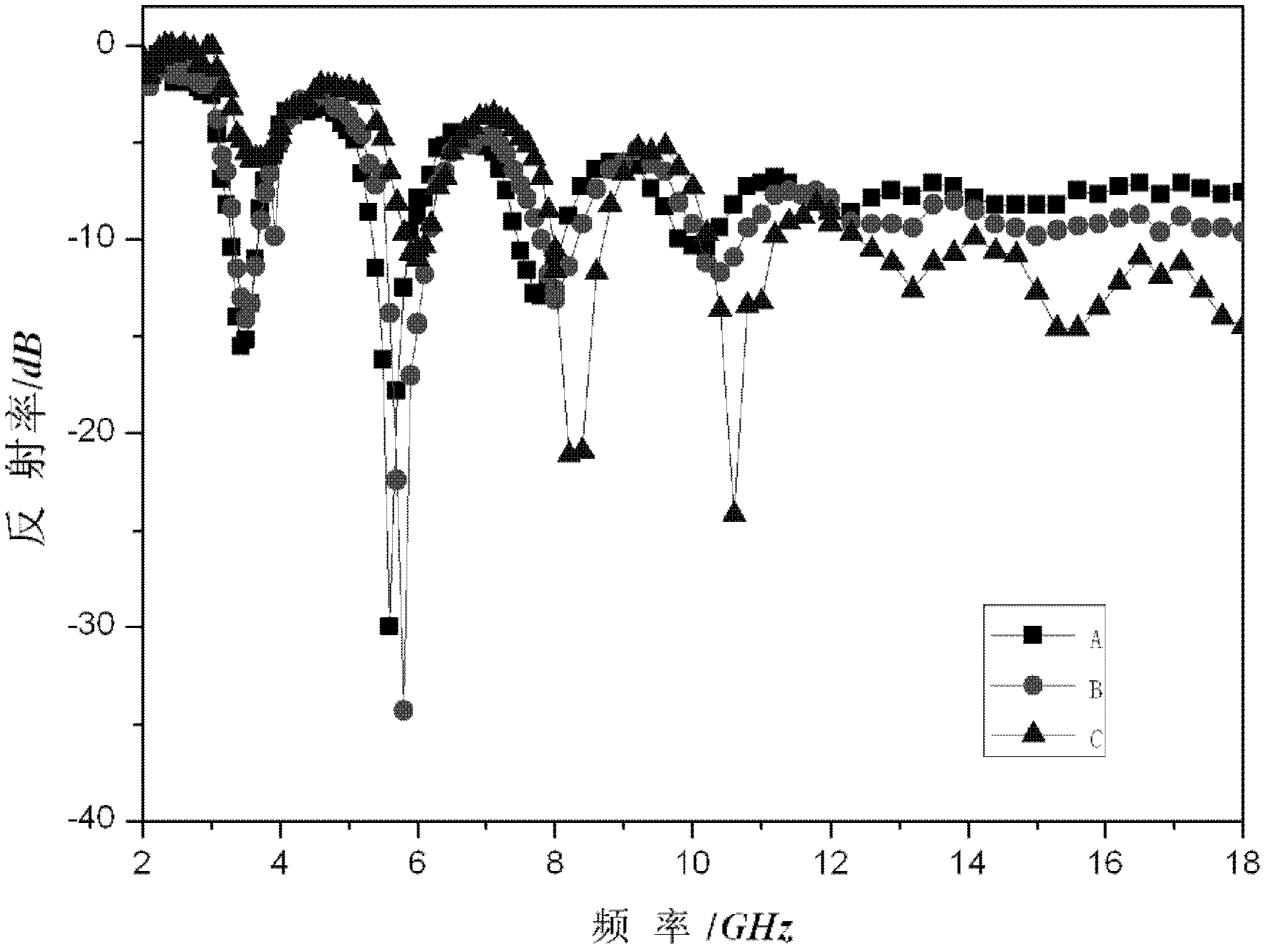

[0044] The microwave-absorbing performance test was carried out on the microwave-absorbing material prepared in this embodiment, and the results are shown in A in the accompanying drawing.

Embodiment 2

[0046] In the present embodiment, each raw material weight ratio is as follows:

[0047] The basic proportion of pumice concrete with electromagnetic wave absorption function is: cement: water: sand: pumice aggregate: carbon black: polycarboxylate superplasticizer (water agent) = 1: 0.43: 1.60: 0.70: 0.01: 0.02.

[0048] Prepare as follows:

[0049] (1) Use hydroxyl iron as a wave absorbing agent, and disperse the wave absorbing agent in ordinary Portland cement;

[0050] (2) Add the sand to the mixer and stir together with cement and wave absorbing agent;

[0051] (3) After the pumice aggregate is saturated with water, add it to the mixer and stir together;

[0052] (4) Add water and polycarboxylate high-efficiency water reducer to mix;

[0053] (5) Casting mold: inject the evenly stirred material into the mold and form it;

[0054] (6) Demoulding: Demoulding becomes the wave-absorbing pumice concrete product in the final shape.

[0055] The microwave-absorbing performan...

Embodiment 3

[0057] In the present embodiment, each raw material weight ratio is as follows:

[0058] The basic proportion of pumice concrete with electromagnetic wave absorption function is: cement: water: sand: pumice aggregate: carbon black: naphthalene superplasticizer (powder) = 1:0.43:1.60:0.52:0.01:0.015.

[0059] Prepare as follows:

[0060](1) Use hydroxyl iron and carbon black as a wave absorbing agent, and disperse the wave absorbing agent and naphthalene-based superplasticizer into Portland cement;

[0061] (2) Add the sand to the mixer and stir together with cement and wave absorbing agent;

[0062] (3) After the pumice aggregate is saturated with water, add it to the mixer and stir together;

[0063] (4) add water separately;

[0064] (5) Molding: inject the well-mixed material into the mold and form it;

[0065] (6) Demoulding: Demoulding becomes the wave-absorbing pumice concrete product in the final shape.

[0066] The microwave-absorbing performance of the high-absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com