Method for low-temperature rapid sintering of alumina-based transparent ceramics with high thermal conductivity through hot pressing

A high thermal conductivity, alumina-based technology, applied in the field of low-temperature hot pressing and rapid sintering of high-thermal conductivity alumina-based transparent ceramics, can solve the problems of insufficient heat dissipation, LED grain interface affecting luminous efficiency and luminous life, etc. Achieve good performance and effect, solve the effect of high sintering temperature and reduce sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

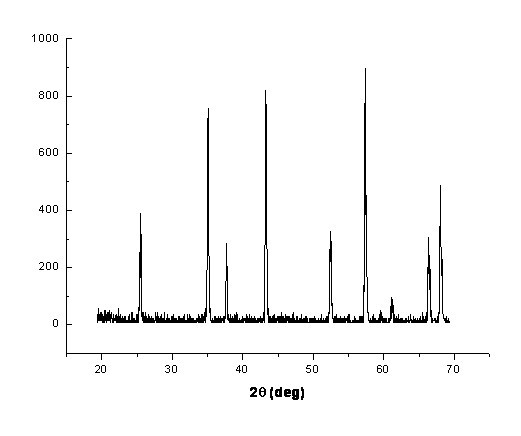

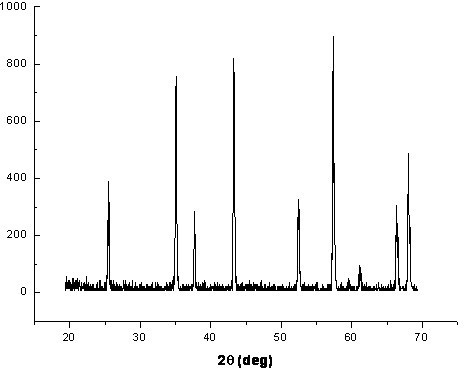

Image

Examples

Embodiment Construction

[0010] Further illustrate substantive characteristics and remarkable advantages of the present invention below by embodiment.

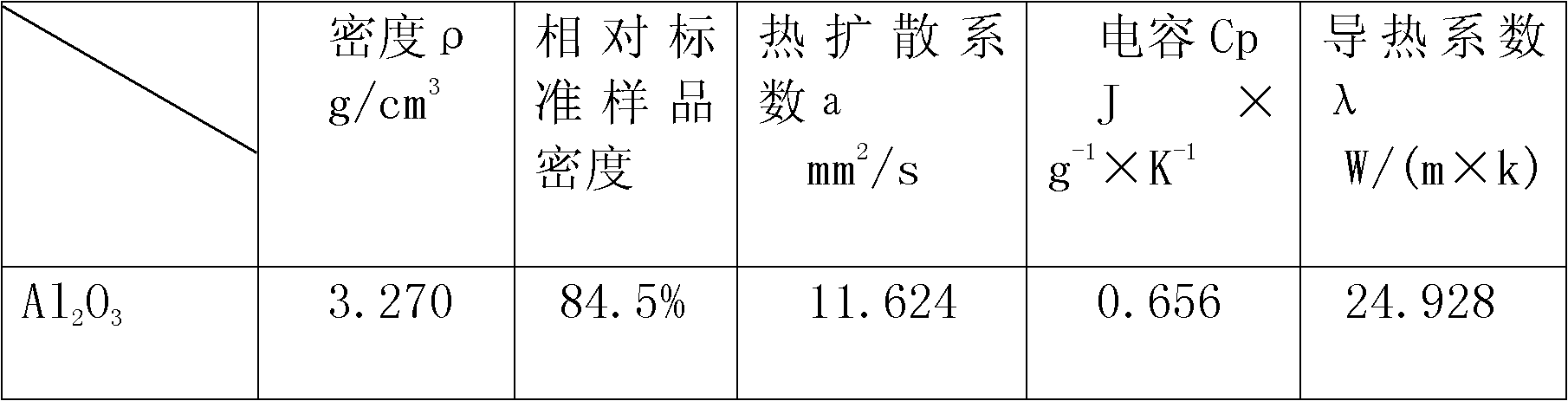

[0011] According to alumina + (lithium silica carbonate) [Al 2 o 3 +(0.4mol%SiO 2 0.4mol%Li 2 CO 3 )] for matching. Ceramics with a molar ratio of alumina: silicon dioxide: lithium carbonate = 0.992: 0.004: 0.004 were synthesized by hot pressing. Firstly, alumina is used as the raw material of the main formula, and the proportioning is carried out according to the formula, the materials are mixed, pulverized with a planetary ball mill, dried, and then the second batching is carried out, and the sintering aid lithium carbonate and silicon dioxide are added according to the above proportioning ratio. , then pulverize and add glue with a planetary ball mill, and then use a DC rapid hot-press sintering machine to heat at 1370°C for 2 minutes and pressurize 3t for sintering, then grind the sintered samples, and then perform performance tests and measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com