Preparation method of polycarboxylic copolymer with high solid content

A technology of high solid content, polycarboxylic acid, applied in the field of preparation of high solid content polycarboxylate water reducing agent, can solve the problems of long production cycle and low production efficiency, and achieve lower product price, no formaldehyde content and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

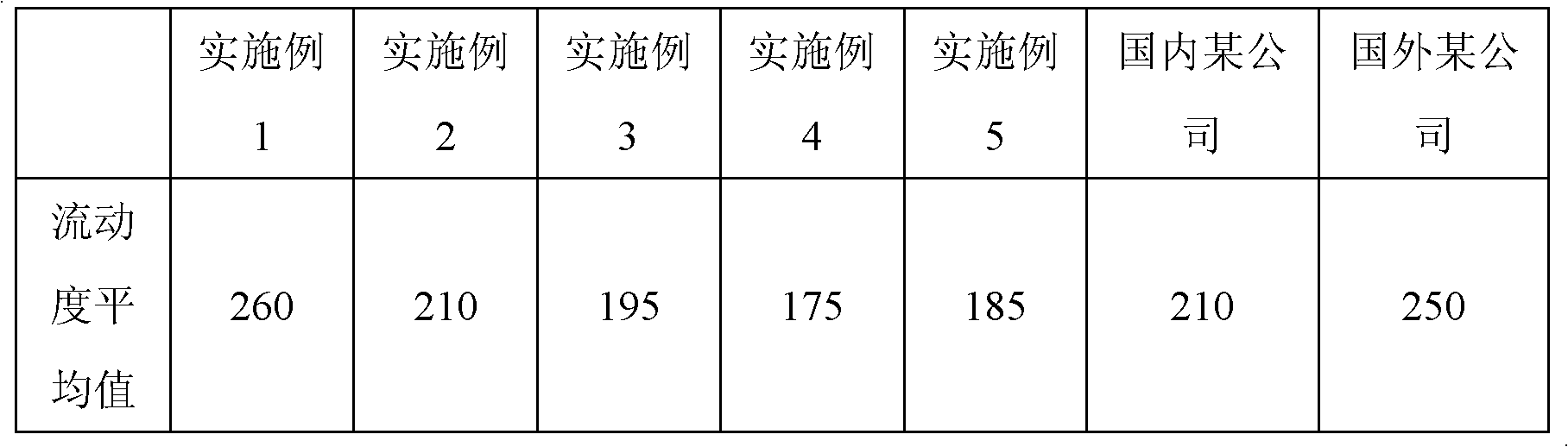

Examples

Embodiment 1

[0027] 1) Add 100 grams of methoxypolyethylene glycol with a molecular weight of 2000 in a reactor equipped with a stirring device, 0.04 grams of inhibitor hydroquinone, 7.2 grams of monomeric acrylic acid, 2 grams of catalyst concentrated sulfuric acid, and heat to 115° C., stirred and reacted for 5 hours to obtain an esterified liquid.

[0028] 2) Control the temperature to 80°C, add dropwise a mixed solution of 10.08 g of acrylic acid and 0.9 g of chain transfer agent mercaptoacetic acid in the esterification solution, and the dropwise addition time is 2 hours, while adding the initiator benzyl peroxide in batches Acyl 2.4 g. After keeping the temperature for 1 hour, add the aqueous solution of the initiator ammonium persulfate dropwise for 1 hour, the reaction temperature is 60°C, and keep the temperature for 1 hour.

Embodiment 2

[0030] 1) Add 100 grams of methoxypolyethylene glycol with a molecular weight of 2000 in a reactor equipped with a stirring device, 0.04 grams of inhibitor hydroquinone, 6.48 grams of monomeric acrylic acid, 2 grams of catalyst concentrated sulfuric acid, and heat to 115° C., stirred and reacted for 5 hours to obtain an esterified liquid.

[0031] 2) Control the temperature at 80°C, add dropwise a mixed solution of 10.08 grams of acrylic acid, 1.7 grams of hydroxyethyl acrylate and 0.9 grams of chain transfer agent mercaptoacetic acid in the esterification solution, and the dropping time is 2 hours. Add 2.4 grams of initiator benzoyl peroxide. After keeping warm for 1 hour, add the initiator ammonium persulfate aqueous solution dropwise for 1 hour, the reaction temperature is 60°C, and keep warm for 1 hour.

Embodiment 3

[0033] 1) in the reactor that stirring device is housed, adding molecular weight is 100 grams of methoxypolyethylene glycol of 2000, 0.04 grams of inhibitor hydroquinone, 9 grams of monomer acrylic acid, 1.5 grams of catalyzer p-toluenesulfonic acid, Heating to 115° C., stirring for 5 hours to obtain an esterification solution.

[0034] 2) Control the temperature at 80°C, add 14.7 grams of maleic anhydride, dropwise add a mixed solution of 2 grams of styrene and 0.7 grams of chain transfer agent mercaptoacetic acid, dropwise for 2 hours, and add esterification solution in batches while dropping And initiator benzoyl peroxide 1.8 grams, insulation 1 hour gets final product, and product is solid after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com