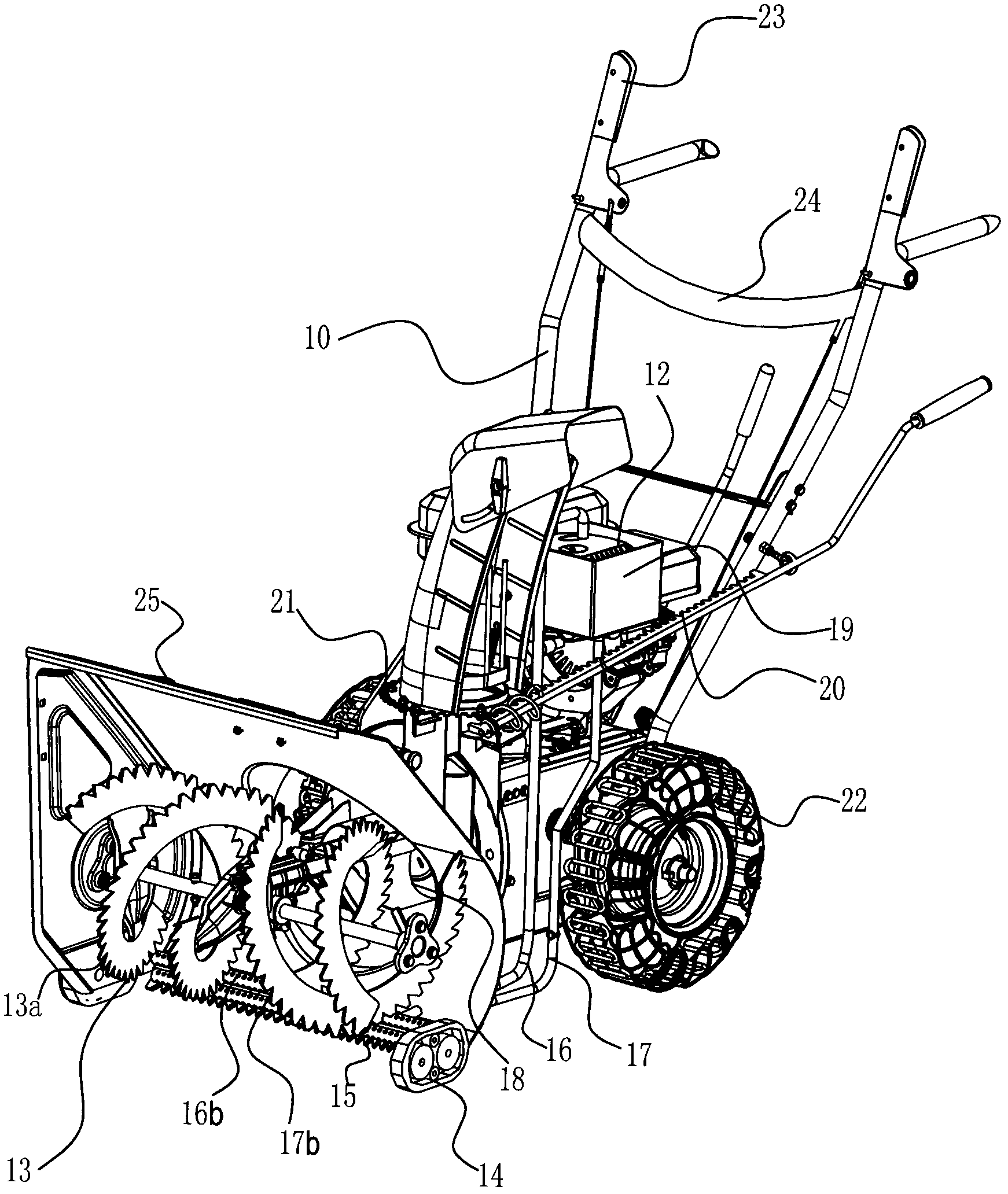

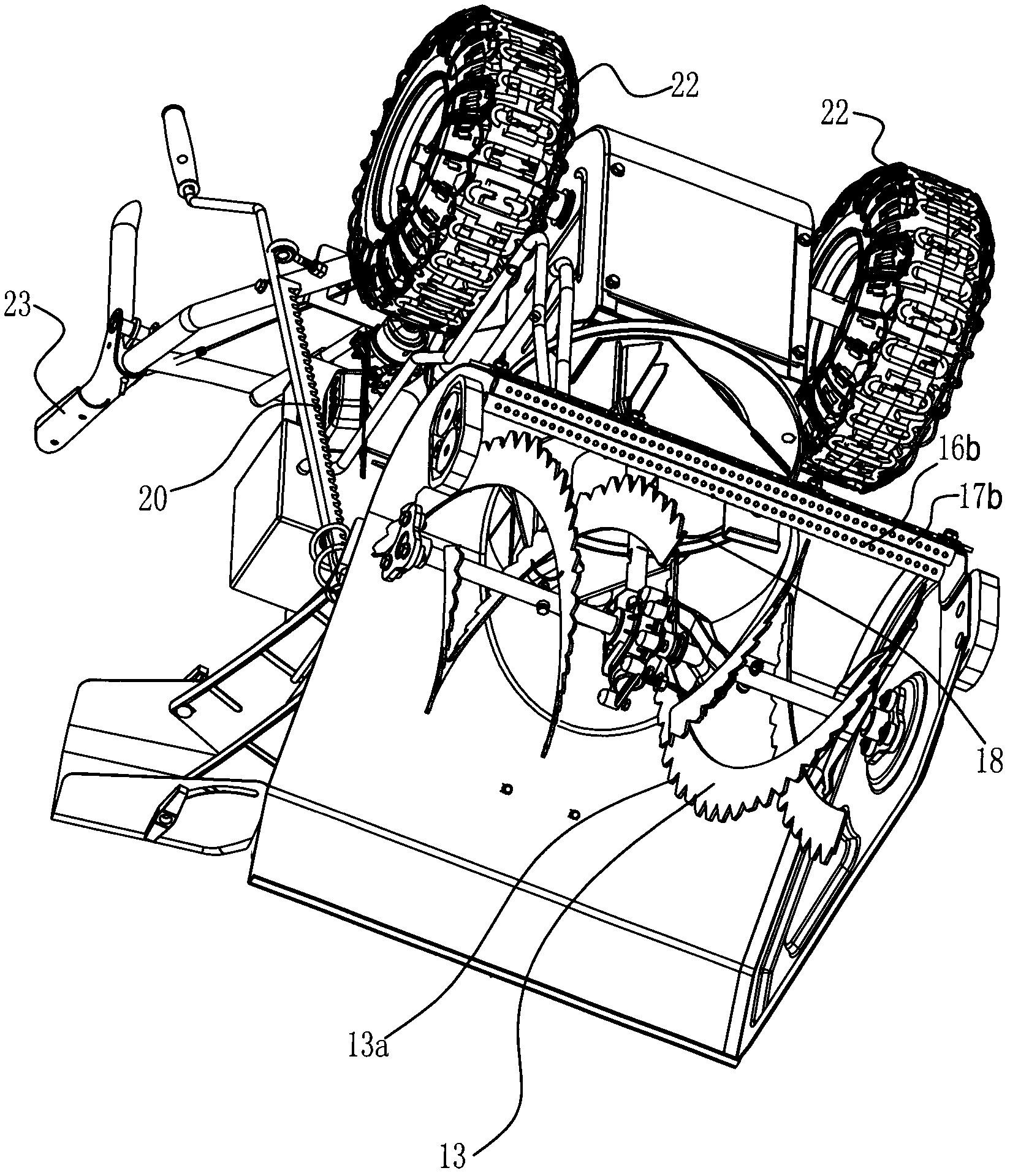

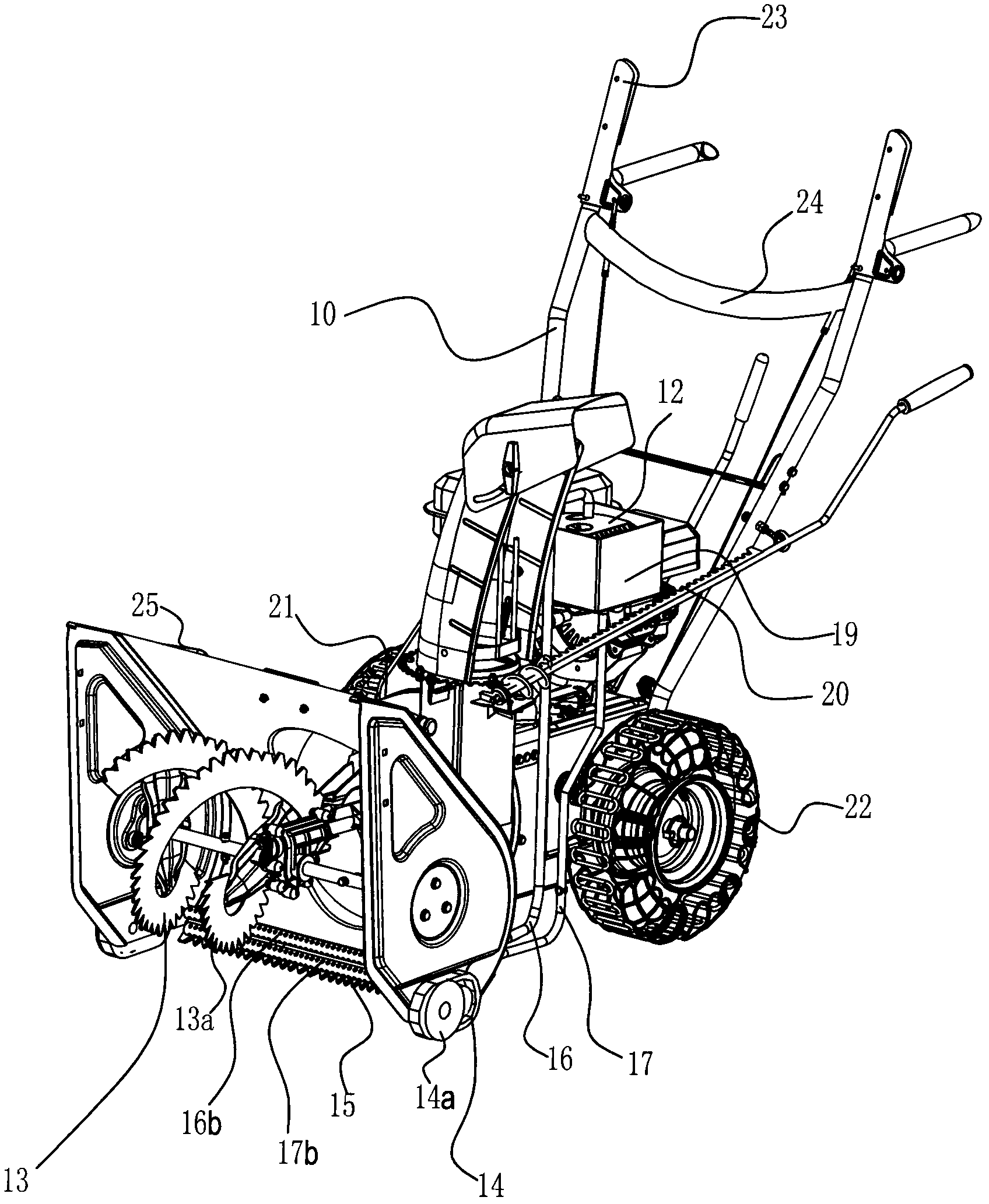

Snow plough with antiskid chains, ice tooth and snow brush auger, heat transfer steam tank and front exhaust pipe

A technology of snow chains and snowplows, which is applied in snow surface cleaning, construction, cleaning methods, etc., and can solve problems such as affecting safety, insufficient snow intake, and limited noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] With reference to the suggestion and method of the present invention, the original snowplow can be refitted; the outer cover without noise reduction effect is changed into two chambers with noise reduction effect, and the three-chamber type silencer becomes a five-chamber silencer. The function has been greatly improved, and the cost is similar to the original cover. The five-chamber muffler originally used on the lawn mower is still usable by slightly changing the installation position and adapting it to the snowplow.

[0066] Also can refer to suggestion and the way of the present invention, make refit on original snowplow; Remove the outer cover that does not have sound-absorbing effect originally, still use three-chamber muffler, or use five-chamber muffler, see the different requirements of different customers, in The muffler is equipped with a heat transfer steam tank and a front exhaust pipe. It is best to use a front exhaust pipe with noise reduction to greatly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com