Signal fusion detection method and signal fusion detection system of automobile wheel hub ferrite content

A technology of signal fusion and automobile wheel hub, applied in the field of detection, can solve the problems of not meeting the rapid detection of ferrite content of as-cast automobile wheel hub, not eliminating the interference of detection signals, and missing detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

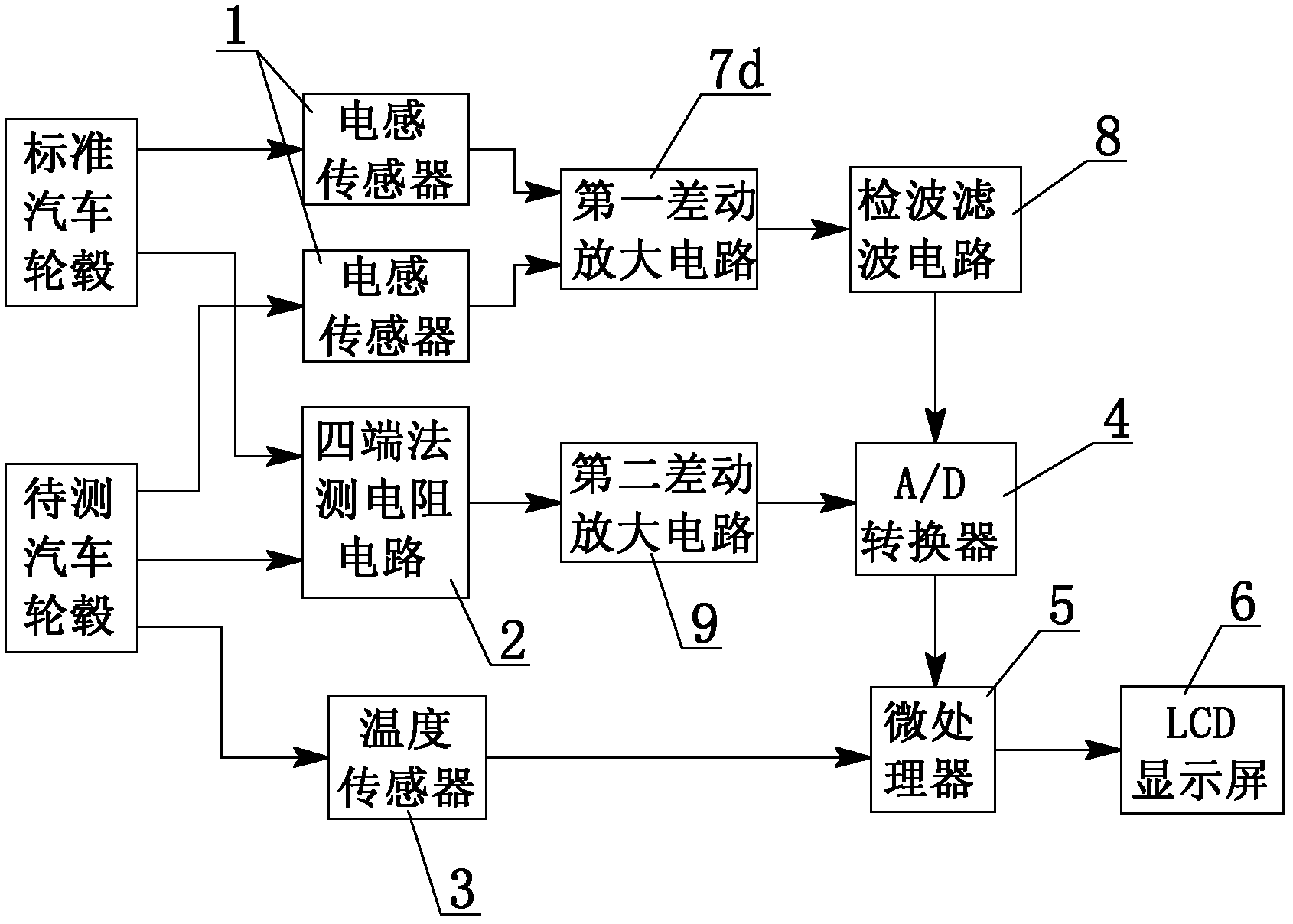

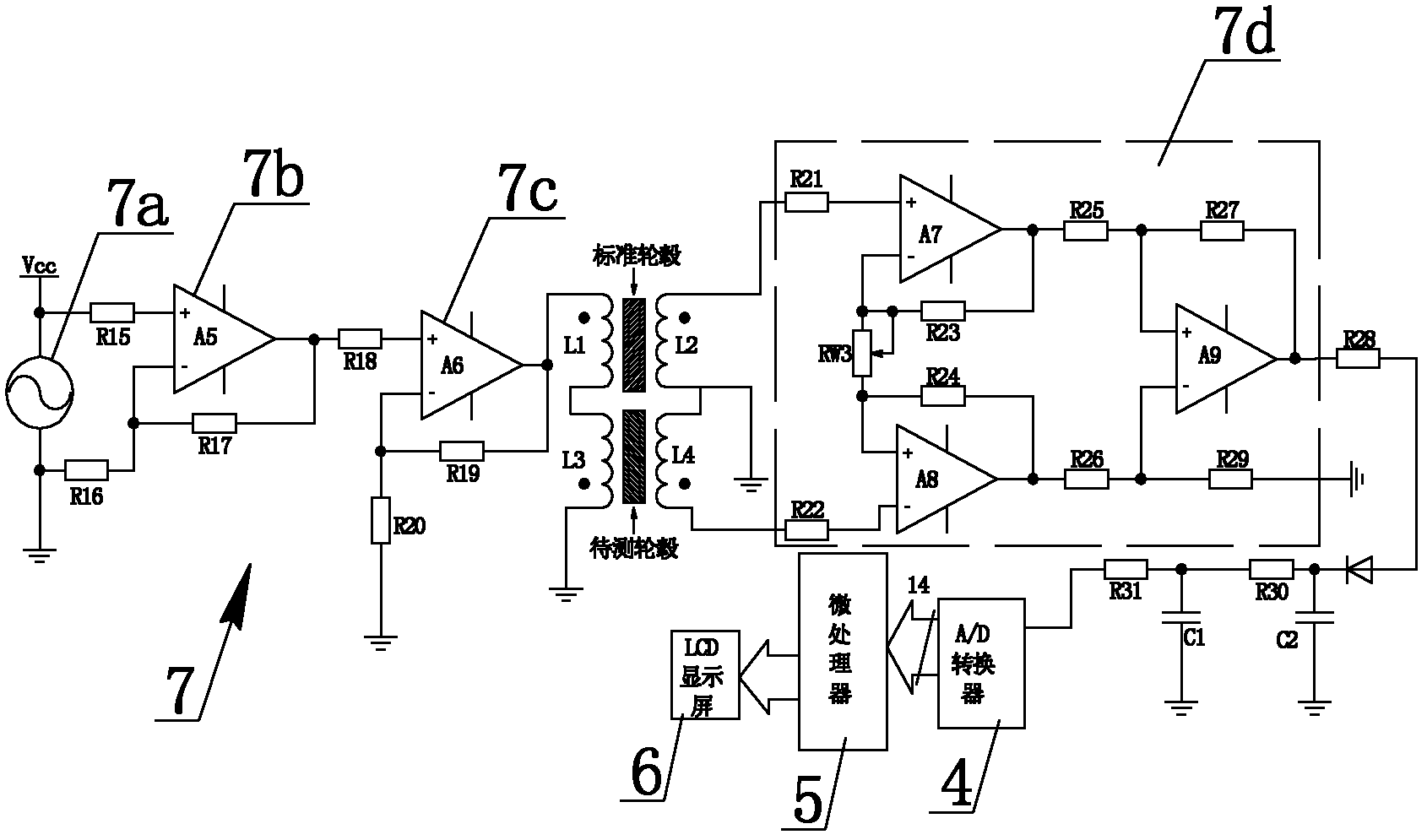

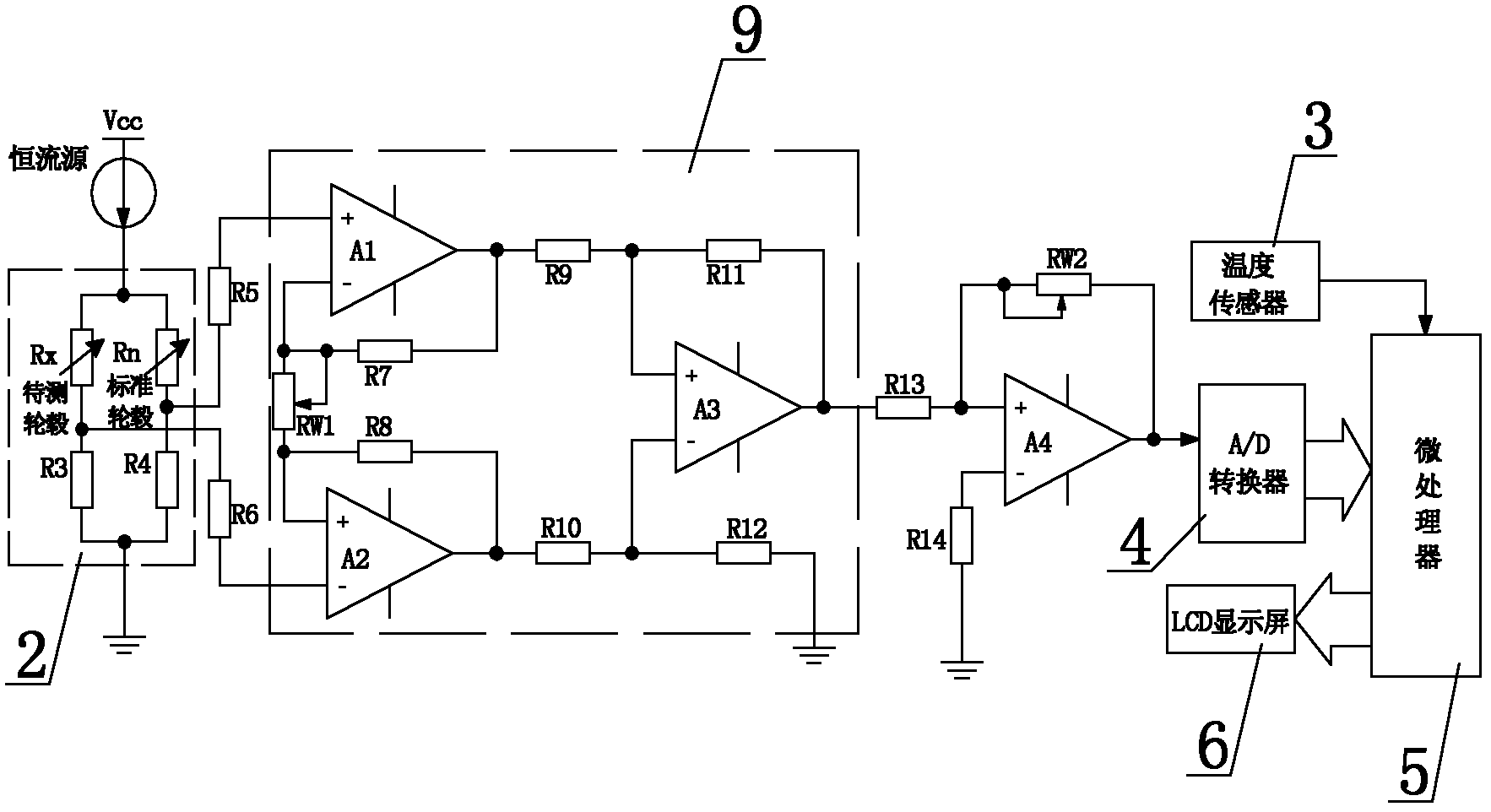

[0021] refer to Figure 1 to Figure 3 As shown, the signal fusion detection system of a kind of automobile hub ferrite content of the present invention, this detection system comprises two inductance sensors 1, four-terminal method measuring resistance circuit 2, temperature sensor 3, A / D converter 4, micro Processor 5 and LCD display screen 6; described inductance sensor 1 is arranged on the standard wheel hub and the wheel hub to be measured respectively, and the input end of described four-terminal method measuring resistance circuit 2 is respectively connected to standard by two groups of altogether four probes The hub and the hub to be tested, the signal output end of the inductive sensor 1 and the output end of the four-terminal method resistance circuit 2 are respectively connected to the A / D converter 4, and the signal output end of the inductive sensor 1 is connected to the A / D The circuit between the converters 4 is connected with a detection filter circuit 8; the A / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com