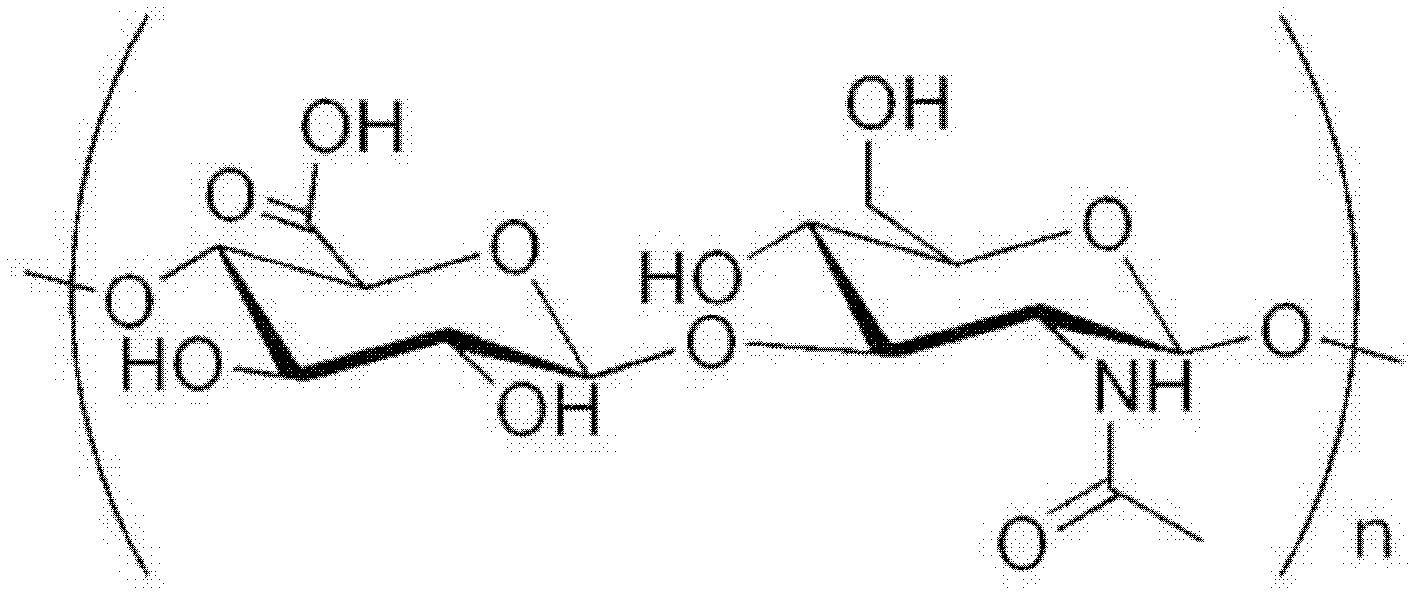

Method for manufacturing low molecular weight hyaluronic acid

A hyaluronic acid and low-molecular-weight technology, which can be used in medical preparations containing active ingredients, skin care preparations, pharmaceutical formulations, etc., can solve problems such as low quality and increased costs, and achieve the effect of simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

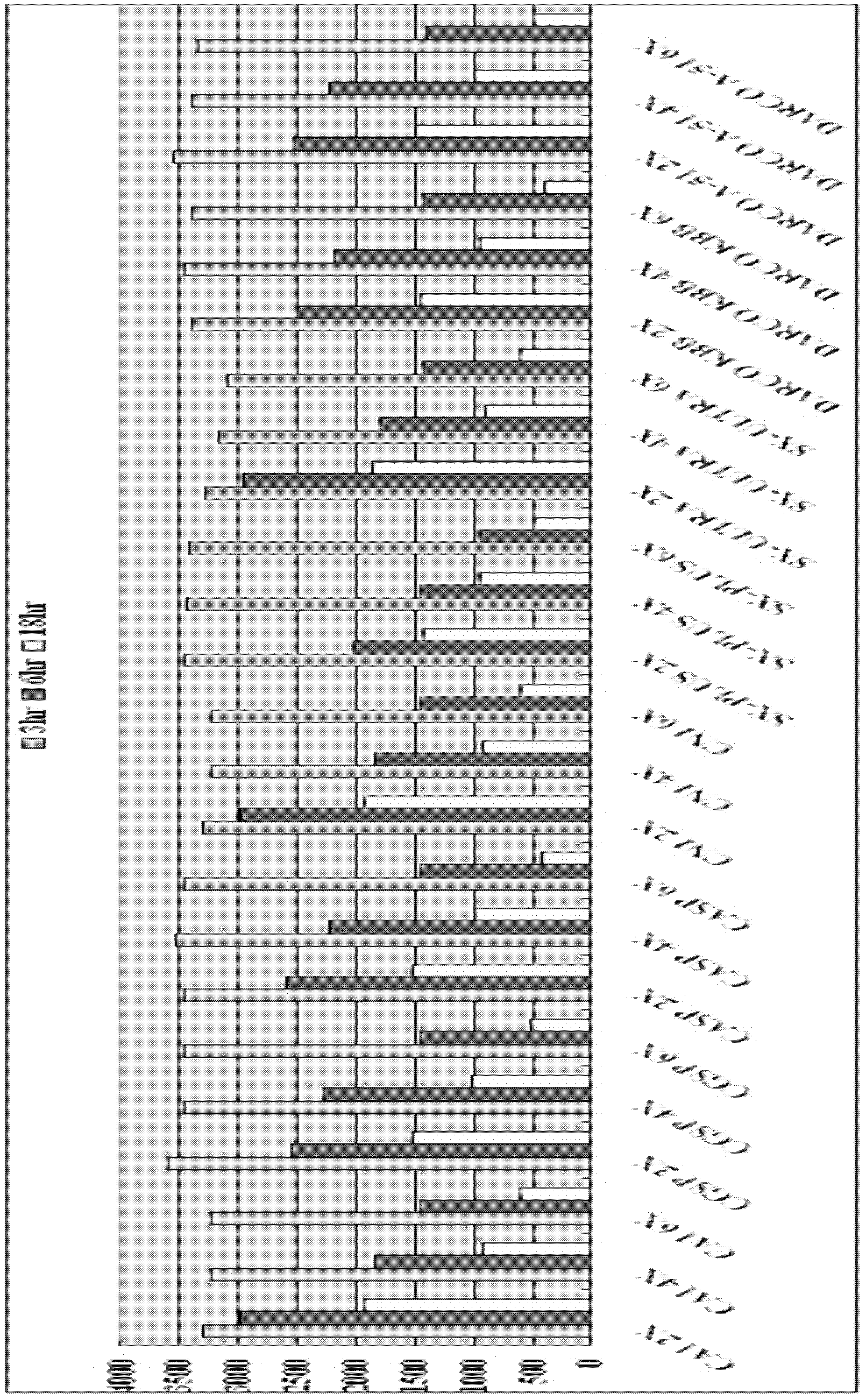

[0060] Method for producing low-molecular-weight hyaluronic acid using CA1 activated carbon

[0061] In this example, the raw material for the production of low-molecular-weight hyaluronic acid used an adjusted substance isolated and purified from a culture obtained by culturing Streptococcus ID9102 (KCTC11395BP) as a production strain, and the average value of hyaluronic acid contained in the raw material was The molecular weight is 3.5 million Da, and the concentration of endotoxin far exceeds 0.5 EU / mg.

[0062] First, the culture conditions are as follows.

[0063] Use ID9102 (KCTC11395BP) in Streptococcus as the production strain of hyaluronic acid, glucose 40-100g / L, yeast X2-5g / L, old peptone 10-20g / L, magnesium sulfonate 0.5-1g / L, monophosphate The aerobic conditions of potassium hydrogen 1-5g / L, sodium chloride 2-10g / L, glutamic acid 0.1-1g / L, pH6.0-7.0, 32-37℃, 0.1-1vvm were carried out in a 75L fermenter to cultivate.

[0064] The basic conditions of the reacti...

Embodiment 2

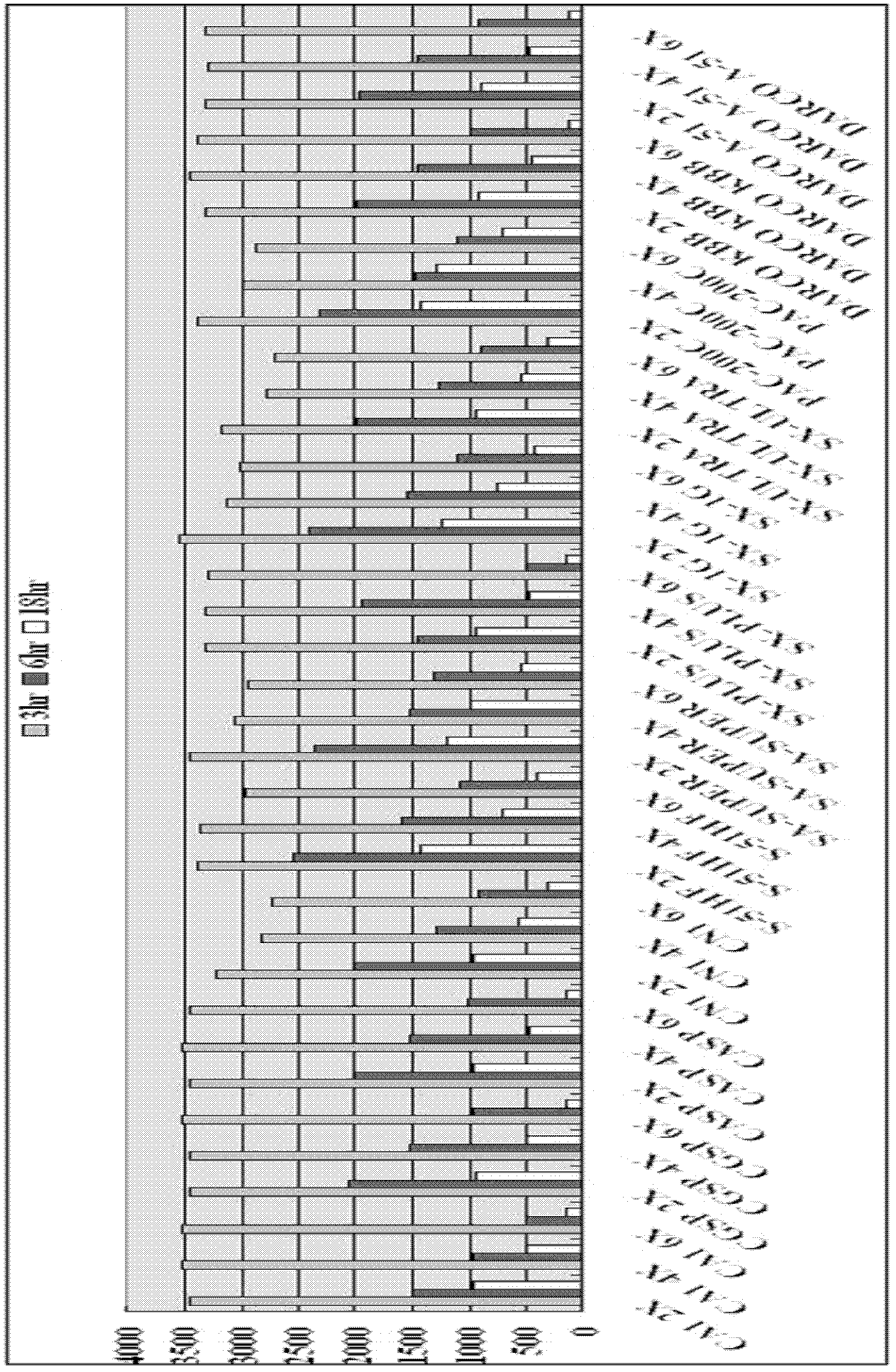

[0071] Method for producing low-molecular-weight hyaluronic acid using CGSP activated carbon

[0072] The hyaluronic acid sample and reaction conditions used in were used, but Norit CGSP (hereinafter referred to as CGSP) activated carbon was used instead of CA1 activated carbon and a hydrolysis vehicle was used to compare and analyze low molecular weight transparent Acid production capacity.

[0073] The sample collection time is 3 hours, 6 hours, and 18 hours. After the reaction, each sample is taken and analyzed according to the above-mentioned analysis method for endotoxin, hyaluronic acid concentration, and average molecular weight, and the results obtained are shown in [Table 2]. It can be confirmed that as the reaction temperature increases similarly to CA1 activated carbon, the decomposition ability of CGSP activated carbon is improved, and the speed of low molecular weight is accelerated. Under the conditions of 25°C and CGSP 4X, 1 million Da of hyaluronic acid can...

Embodiment 3

[0079] Method for producing low-molecular-weight hyaluronic acid using CASP activated carbon

[0080] The same conditions as those used in were used. A comparative analysis was performed using Norit CASP (hereinafter referred to as CASP) activated carbon instead of CA1 activated carbon.

[0081] The sample collection time was 3 hours, 6 hours, and 18 hours. After the reaction, each sample was taken and analyzed according to the above analysis method for endotoxin, hyaluronic acid concentration, and average molecular weight, and the results as [Table 3] were obtained. It was confirmed that as the reaction temperature increased to be similar to CA1 and CGSP activated carbon, the decomposition power of CASP activated carbon also increased and the speed of low molecular weight accelerated. Under the conditions of 25°C and CASP 4X, hyaluronic acid of 1 million Da can be obtained in 18 hours, and at 35°C, it shows the same level of molecular weight decomposition ability at a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com