Method for recovering carbon source and nitrogen and phosphorus elements from surplus sludge

A technology for excess sludge, nitrogen and phosphorus, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as shortage of phosphate rock and lack of carbon sources, and achieve reduction of ammonia nitrogen and orthophosphate load, reduce the amount of hydrochloric acid, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

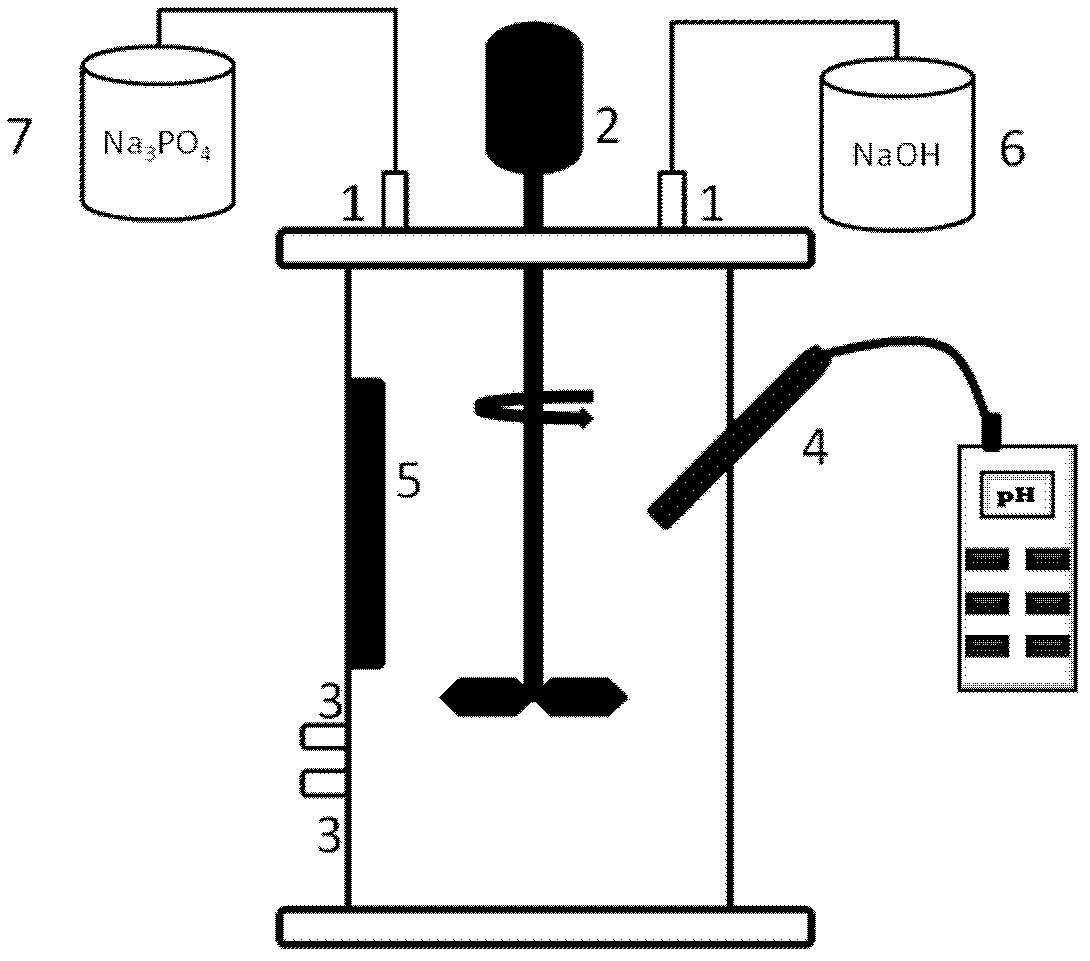

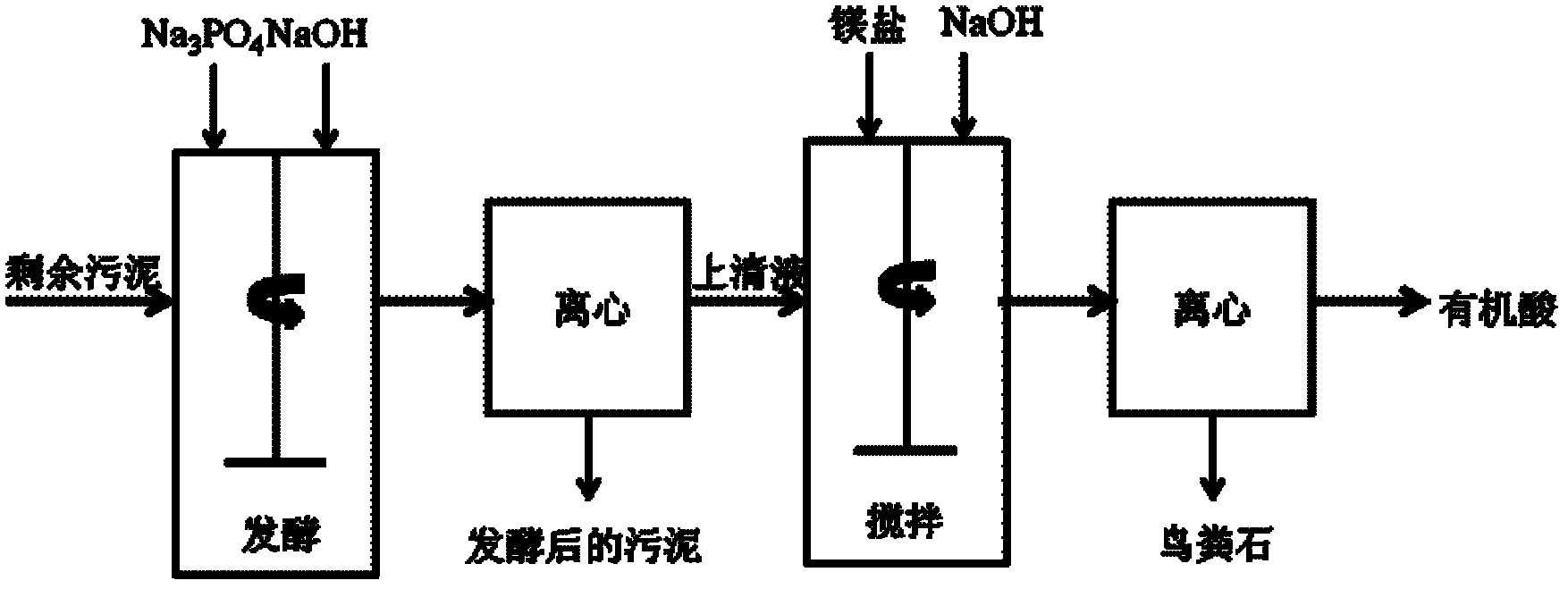

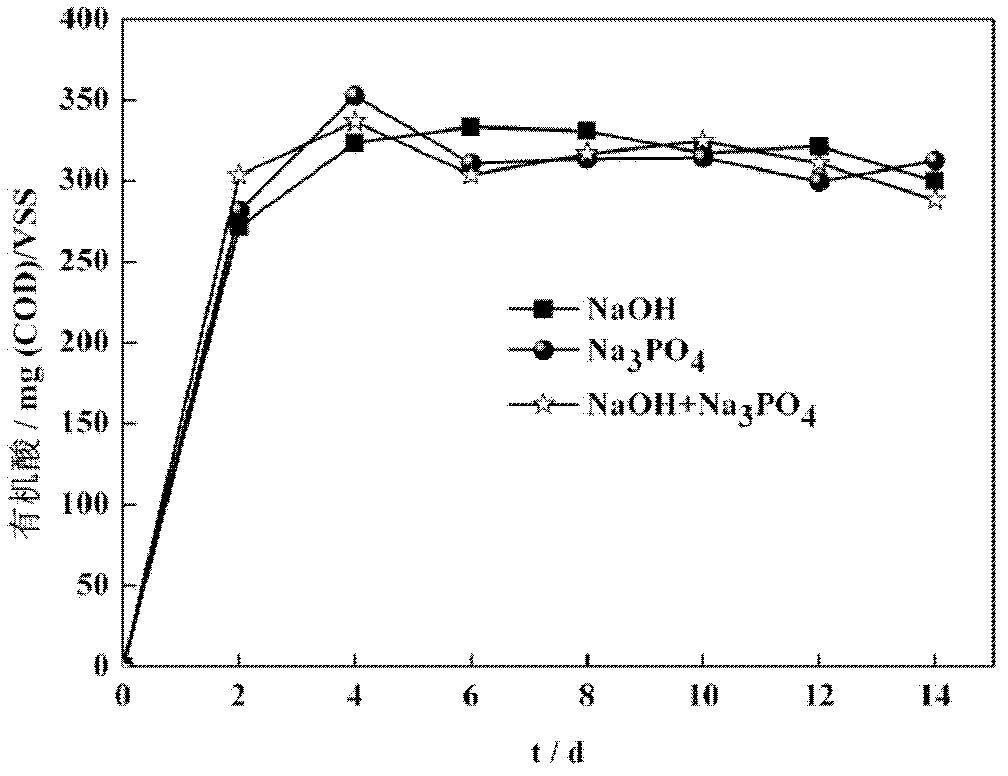

[0048] (1) Take 1L of concentrated residual sludge in the batch activated sludge process reactor (total suspended solids concentration is 9212mg / L, volatile suspended solids concentration is 8007mg / L, pH6.83) into the reactor, First use sodium phosphate particles to adjust the pH of the remaining sludge to 8, then use 2.5mol / L sodium hydroxide solution to adjust the pH of the remaining sludge to 10, aerate nitrogen for 3 minutes, and then ferment in a closed reactor at 35°C. The stirring speed of the device was 100 rpm.

[0049] (2) Take a sample every 2 days, analyze the concentration of ammonia nitrogen and orthophosphate in the fermentation broth, and calculate P / N. When P / N is less than 0.9, add sodium phosphate to adjust P / N and pH value. When P / N is greater than 0.9, use sodium hydroxide to adjust the pH value of the reactor. During the operation of the reactor, the pH value was controlled at 10 ± 0.2.

[0050] (3) After the reactor has been running for 14 days, stop ...

example 2

[0055] (1) Take 1L of concentrated A 2 The remaining sludge in the O reactor (total suspended solids concentration is 10327 mg / L, volatile suspended solids concentration is 8778 mg / L, pH 7.3) is added to the reactor, and sodium phosphate particles are used to adjust the pH value of the remaining sludge to 8.5 , and then use 4mol / L sodium hydroxide solution to adjust the pH of the remaining sludge to 10, aerate nitrogen for 3 minutes and then ferment in a closed reactor at room temperature (20-22° C.), with the stirring speed of the reactor being 200 rpm.

[0056] (2) Take a sample every 2 days, analyze the concentration of ammonia nitrogen and orthophosphate in the fermentation broth, and calculate P / N. When P / N is less than 0.9, add sodium phosphate to adjust P / N and pH value. When P / N is greater than 0.9, use sodium hydroxide to adjust the pH value of the reactor. During the operation of the reactor, the pH value was controlled at 10 ± 0.2.

[0057] (3) After the reactor ...

example 3

[0061] (1) Get 5L of concentrated residual sludge (total suspended solids concentration is 12250mg / L, volatile suspended solids concentration is 10168mg / L, pH7.27) in the batch type activated sludge process reactor after being concentrated and add in the reactor, First use sodium phosphate particles to adjust the pH value of the excess sludge to 8.5, then use 4mol / L sodium hydroxide solution to adjust the pH value of the excess sludge to 10, aerate nitrogen for 3 minutes, and then close the reactor at room temperature (20-22°C ) fermentation, the stirring speed of the reactor is 180rpm.

[0062] (2) Take a sample every 2 days, analyze the concentration of ammonia nitrogen and orthophosphate in the fermentation broth, and calculate P / N. When P / N is less than 0.9, add sodium phosphate to adjust P / N and pH value. When P / N is greater than 0.9, use sodium hydroxide to adjust the pH value of the reactor. During the operation of the reactor, the pH value was controlled at 10±0.2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com