Phosphorus-containing flame retardant, flame-retarding polyester thin film and preparation methods thereof

A technology of flame retardant polyester and polyester film, applied in the field of flame retardant polyester film, can solve the problems of unstable film mechanical properties, large amount of flame retardant added, poor compatibility of film substrates, etc., and achieve high mechanical properties and thermal stability, improved flame retardant properties, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

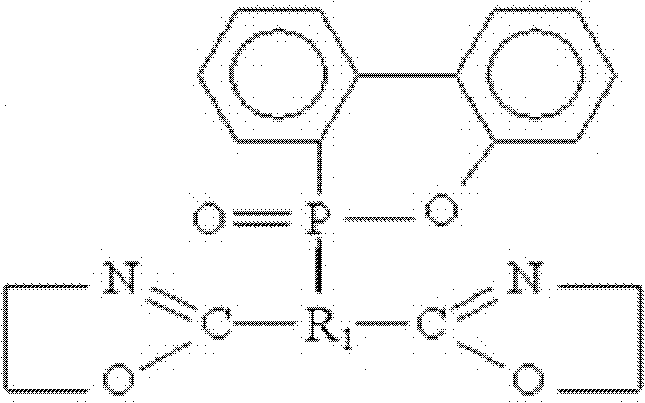

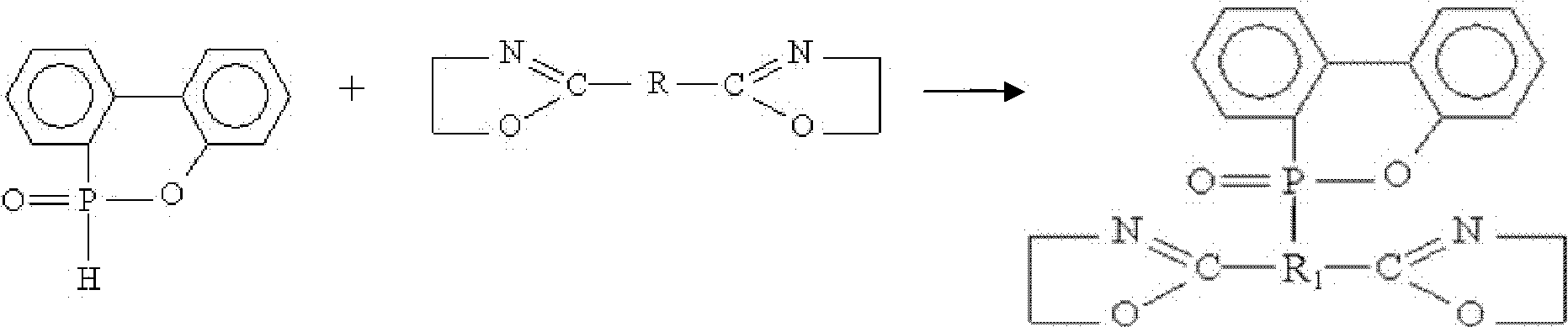

[0050] The preparation method of phosphorus-containing flame retardant provided by the present invention, general reaction formula is as follows:

[0051]

[0052] Raw material I Raw material II

[0053] Raw material I is 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO);

[0054] The raw material II is a bisoxazoline-alkene compound; the molar ratio of the raw material I to the raw material II is: 0.5:0.35-0.5; the preparation method comprises the following steps:

[0055] (1), in N 2 Under the atmosphere, add the measured amount of xylene into the flask, preheat the xylene to 90-100°C, then add the measured amount of raw material I, at this temperature, after heating for 2-2.5 hours, add the measured amount of raw material II, and mix The solution was heated for another 17-20 hours, and then cooled until no more substances were precipitated; the entire addition process and reaction process required N 2 Protect;

[0056] (2), the mixture obtained in step (1) is f...

Embodiment 1

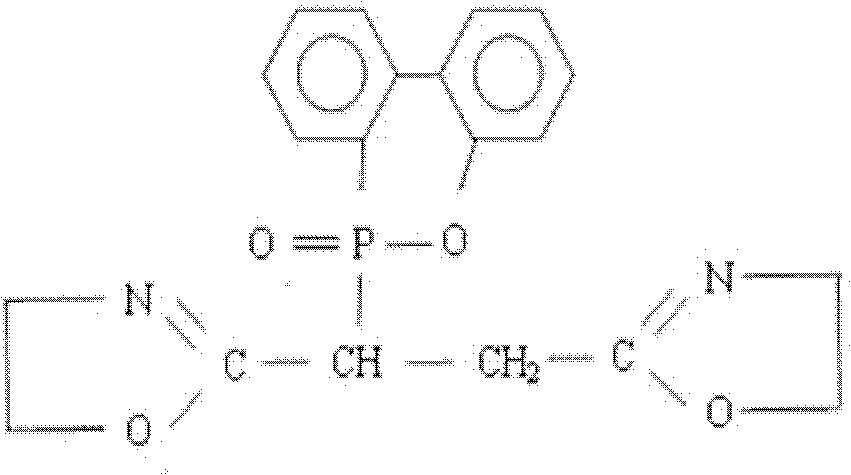

[0073] in N 2 Under the atmosphere, add 200ml of xylene into the flask, preheat the xylene to 90-100°C, add 125g of DOPO, at this temperature, after heating for 2 hours, add 73g of 1,2-bisoxazoline- Ethylene, the mixed solution was heated for another 17 hours, then cooled until no substance was separated out; the resulting mixture was filtered, the filtrate was poured off, and recrystallization was carried out with petroleum ether to obtain the phosphorus-containing flame retardant provided by the present invention. 1 The test results of H-NMR spectrum and infrared spectrum are shown in Table 1.

Embodiment 2

[0075] in N 2 Under the atmosphere, add 200ml of xylene into the flask, preheat the xylene to 90-100°C, add 125g of DOPO, at this temperature, after heating for 2.5 hours, add 80g of 1,2-bisoxazoline- Ethylene, the mixed solution was heated for another 20 hours, and then cooled until no more substances were precipitated; the obtained mixture was filtered, the filtrate was poured off, and petroleum ether was used for recrystallization to obtain the phosphorus-containing flame retardant provided by the invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com