Piezochromism anti-forgery ink

A technology of anti-counterfeiting ink and pressing color, which is applied in the direction of ink, printing and printing of special varieties of printed matter, to achieve the effect of adding comprehensive anti-counterfeiting function, easy features, and simple tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

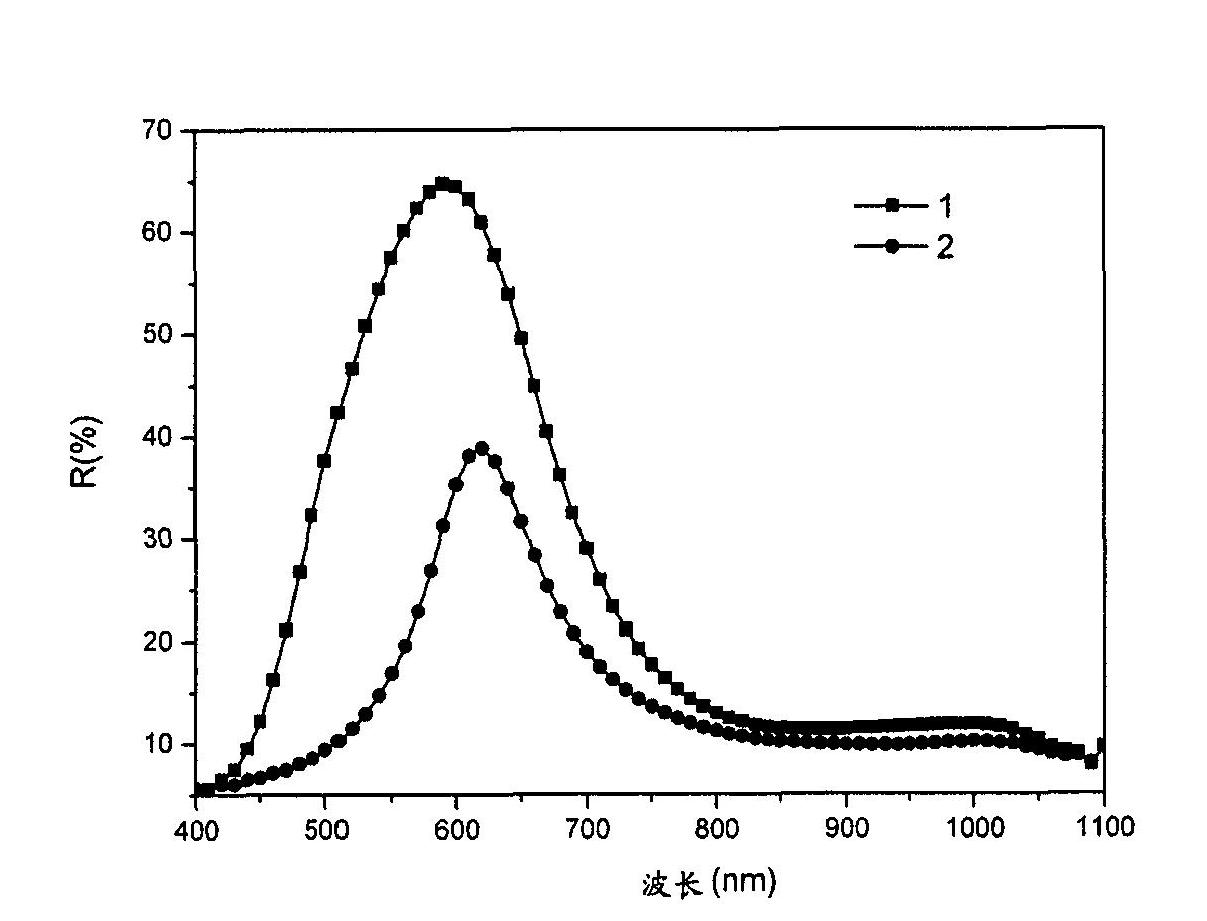

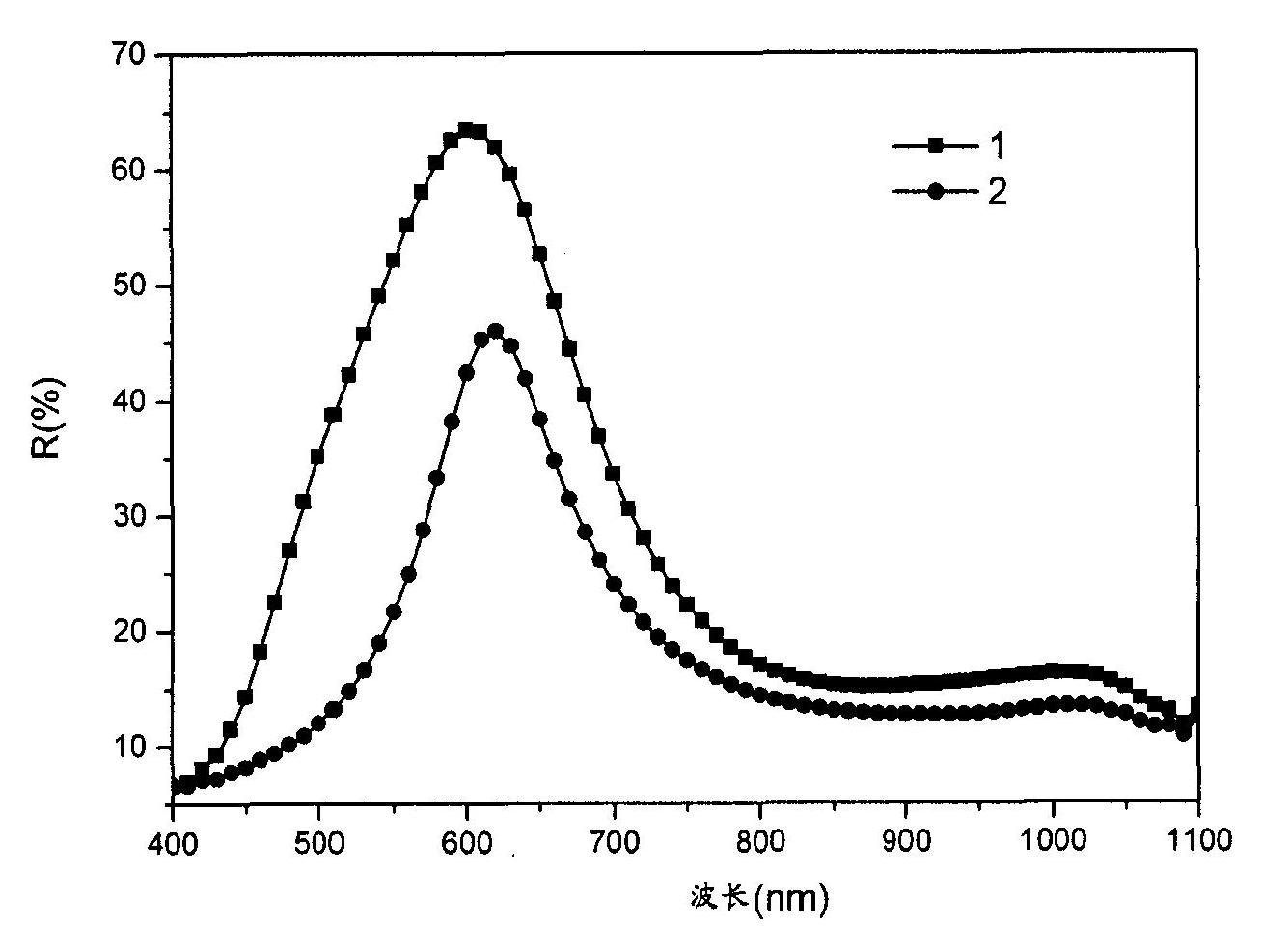

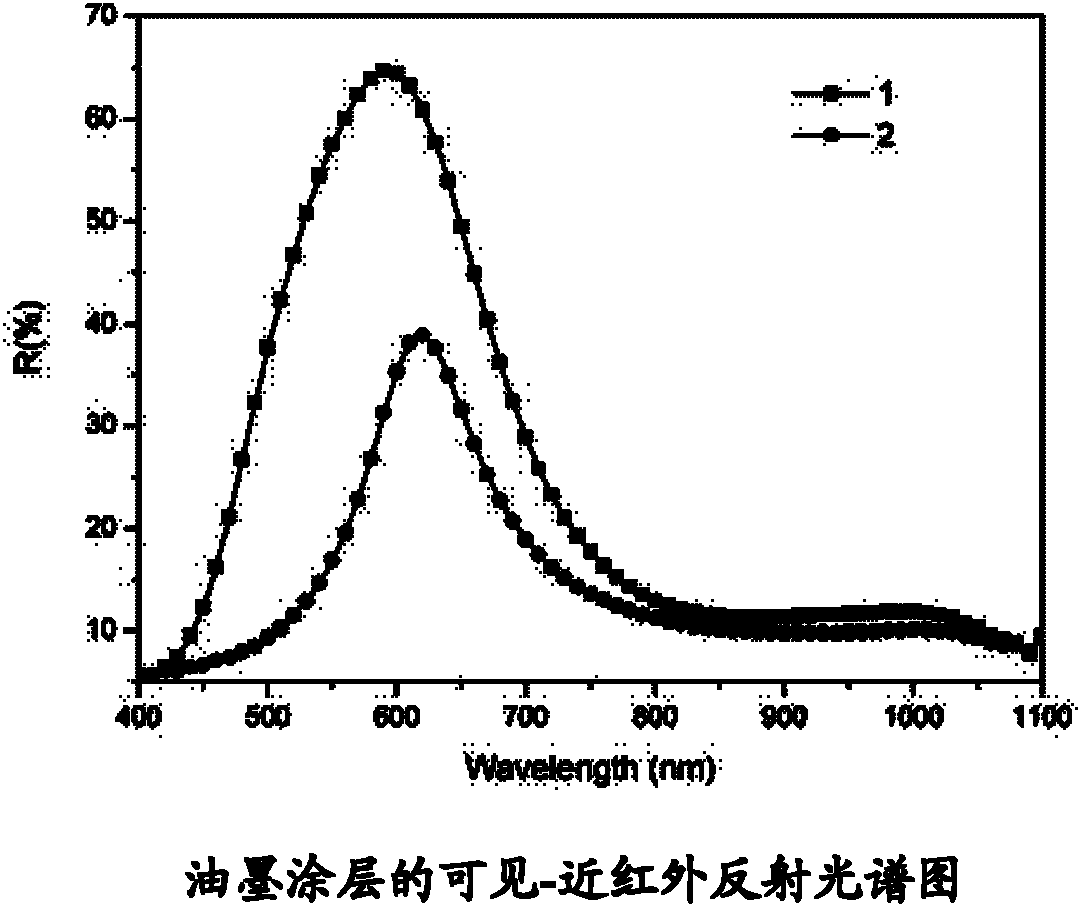

Image

Examples

Embodiment 1

[0053] First, the piezochromic material Fe was synthesized as follows 2 Cr 2.4 Mo 0.6 o 12 : the Fe 2 o 3 , CrO 3 、MoO 3 After mixing and grinding in proportion, they were sintered in air at 900°C for 24h, and then cooled slowly to room temperature. Ball milling was carried out again, and the particle size analysis was carried out by a Master sizer 2000 laser particle size analyzer, and the result showed that the d50 was 15 microns.

[0054] Then, anti-counterfeiting ink was prepared according to the composition listed in Table 1 (by weight percentage). The anti-counterfeiting ink is suitable for use as a paper-based UV screen pressing ink.

[0055] Table 1

[0056] components content(%) Laromer LR9019 (modified epoxy acrylate, Basf) 15 CN965NS (aliphatic urethane acrylate, Sartomer company) 17 Hexylene glycol diacrylate (HDDA) 6 Tripropylene glycol diacrylate (TPGDA) 6 R812S (fumed silica, Degussa company) 2 Fe...

Embodiment 2

[0061] First, obtain piezochromic material Fe as in Example 1 2 Cr 2.4 Mo 0.6 o 12 .

[0062] Then, the piezochromic material is coated in the following manner: 3g of sodium nonylphenol polyoxyethylene ether sulfate and 2g of hexadecane are dissolved in 300ml of water, and 15g of Fe 2 Cr 2.4 Mo 0.6 o 12 . After vigorous emulsification, slowly add 3g of methyl methacrylate and 1.2g of ammonium persulfate, stir at high speed, raise the temperature to 80°C under the protection of nitrogen, react for 4h, then cool the reaction liquid, centrifuge, and coat the polymer in the lower layer The material of the object was taken out, washed repeatedly with water and methanol, and dried. The particle size detection d50 is 16 microns. It can be seen that the coating thickness is 1 micron.

[0063] Then, similarly, the preparation of ink and coating is carried out according to the composition listed in Table 1 in Example 1, the difference is only in the Fe in this example 2 Cr 2...

Embodiment 3

[0066] First, the piezochromatic material CuMo was synthesized as follows 0.8 W 0.2 o 4 : Will (NH 4 ) 2 Mo 2 o 7 and Na 2 WO 4 The aqueous solution is mixed in proportion, heated to 70°C, and CuCl is added dropwise while stirring 2 The solution was fully stirred for 2 hours, and the precipitate was filtered and washed, then sintered at 500°C for 6 hours, and slowly cooled to room temperature. Ball milling was carried out again, and the particle size d50 reached 6.5 microns.

[0067] Then, the piezochromic material is coated in the following way: in a four-necked flask equipped with a reflux condenser and a thermometer, add 10g CuMo 0.8 W 0.2 o 4, 1.2g silane coupling agent and 200g toluene, after stirring, add 2.5g methyl methacrylate and 3.25g butyl acrylate, stir well, then slowly add 0.05g azobisisobutyronitrile, and heat up under nitrogen protection To 70°C, react for 6h, cool, filter with suction, and dry in vacuum. The particle size detection d50 is 8 micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com