Coal pyrolysis device and coal pyrolysis method for improving yield of tar

A technology of tar yield and coal pyrolysis, which is applied in coking ovens, petroleum industry, direct and indirect heating combined dry distillation, etc., can solve the problems of increasing additional investment and reducing the calorific value of gas, so as to reduce the secondary combination and improve Tar yield, effect of enhanced heating action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

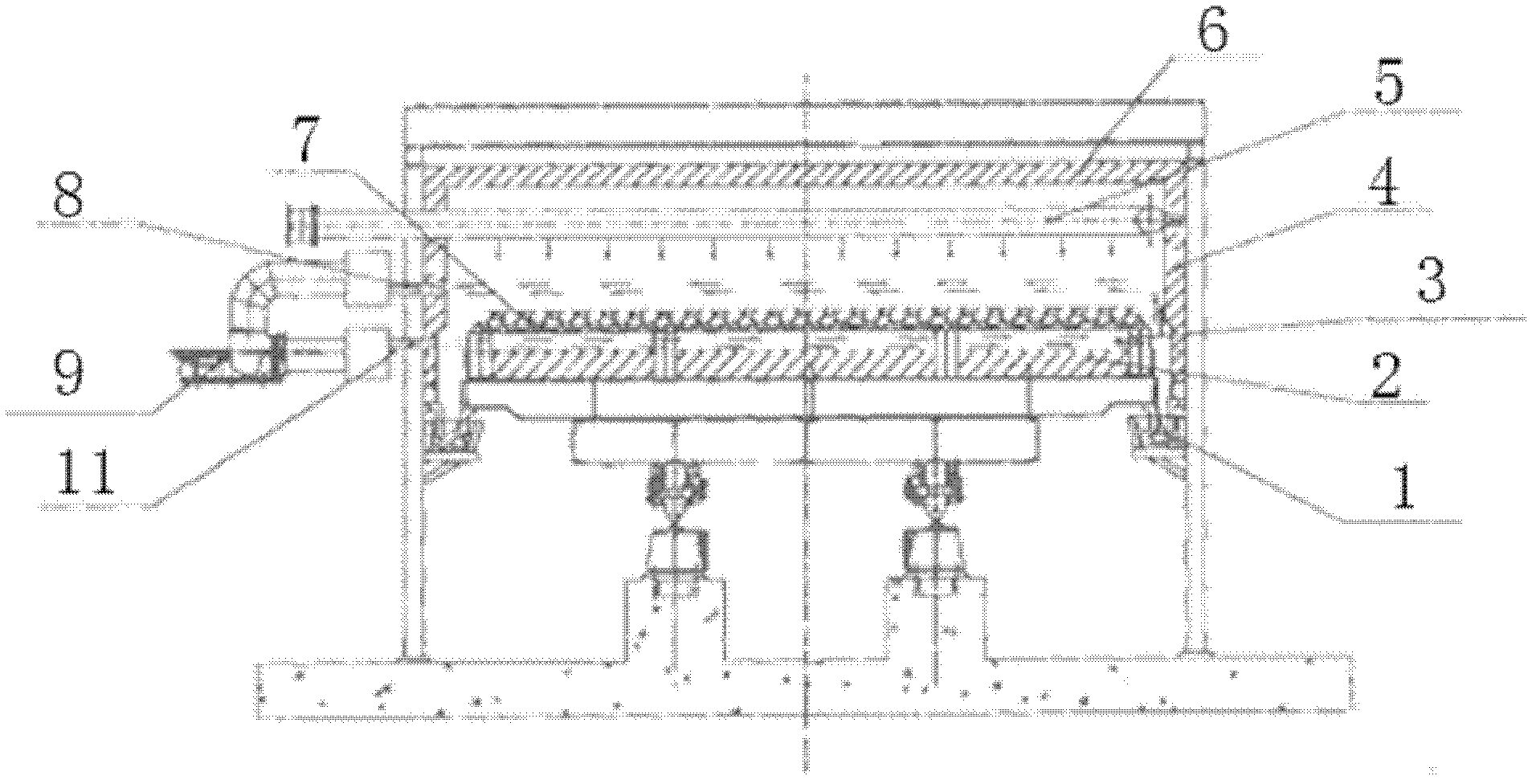

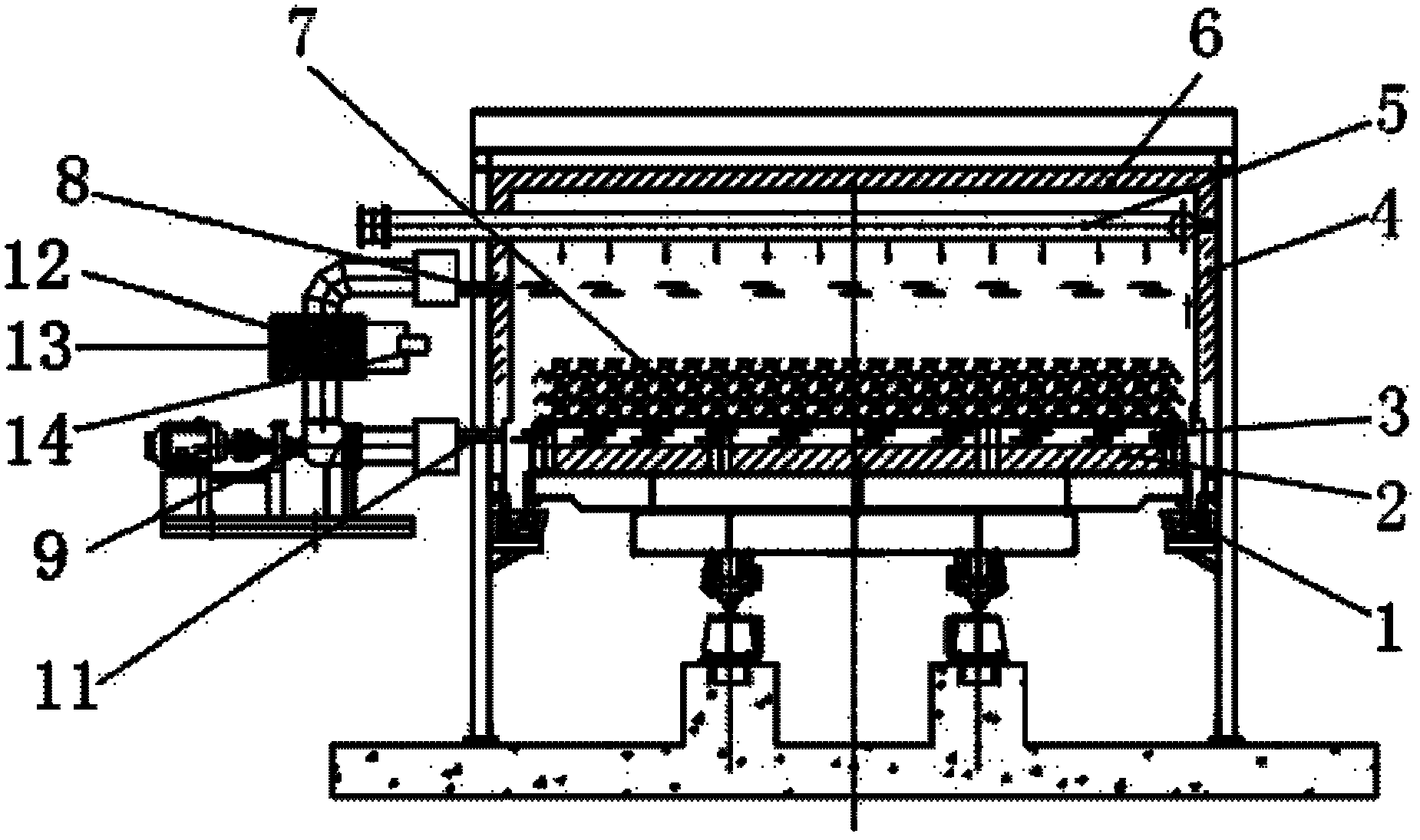

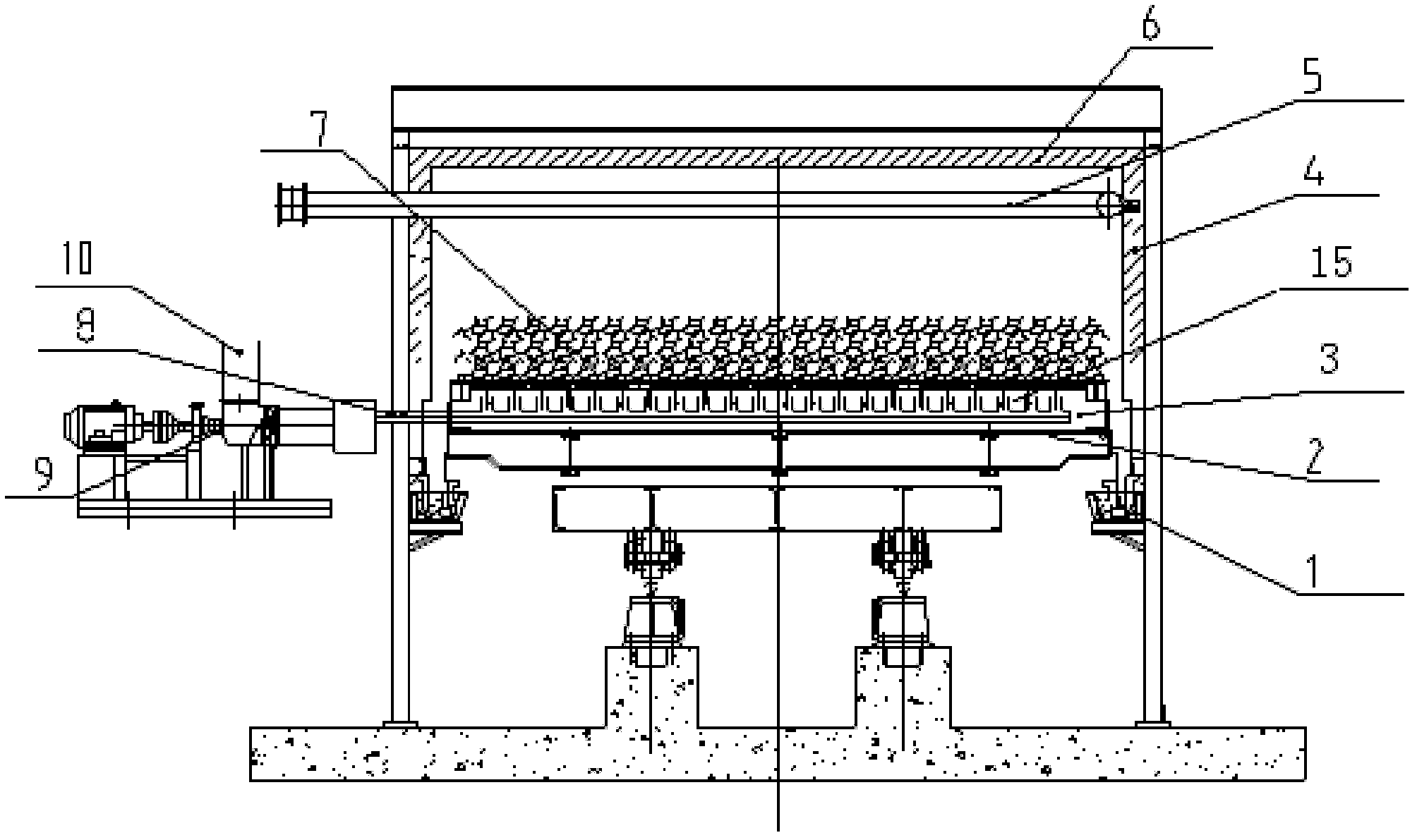

[0017] Such as image 3 As shown, the coal pyrolysis equipment for increasing the tar yield of the present invention includes a body of furnace, the bottom 2 of the body of furnace is provided with a material bed 15 for placing materials 7, between the material bed 15 and the bottom of the furnace 2 It is an overhead space 3, and the material bed 15 is a ventilated material bed; one side of the overhead space 3 is provided with an air inlet 8, and the air inlet 8 is connected with a high-temperature fan 9 and an air outlet 10. The furnace body includes a furnace wall 4, a furnace roof 6 and a rotary furnace bottom 3, a radiant tube 5 for heating is provided in the furnace body, and a water seal groove 1 for sealing is provided between the furnace wall 4 and the rotary furnace bottom 2 .

[0018] The material bed 15 is uniformly provided with dense small holes. The diameter of the small holes is 3-8 mm, and the center-to-center distance between the small holes is 6-11 mm. Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com