Nanometer essence capsule and preparation method thereof

An essence capsule and nano technology, applied in the field of nano essence capsule and its preparation, can solve the problems such as the persistence of aroma function needs to be improved, and achieve the effects of good hand feeling and washability, good utilization rate of raw materials and high surface adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

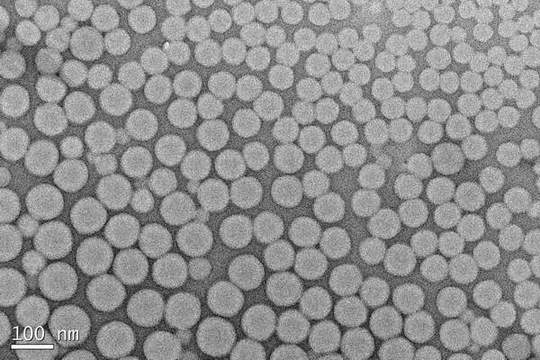

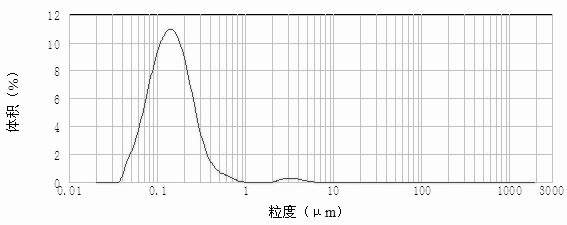

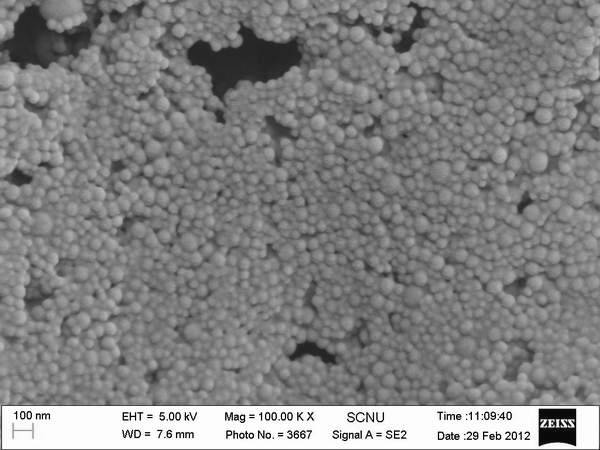

Image

Examples

Embodiment 1

[0029] Mix 200ml deionized water, 15g methyl methacrylate, 5g cologne essence and 6g TO5, and emulsify and disperse at a high speed at 8000 rpm for 30 minutes to obtain a fragrance emulsion containing methyl methacrylate monomer; Transfer to a water bath with a temperature of 60°C, pass through an inert protective gas, maintain a mechanical stirrer at 800 rpm, make 0.9g of ammonium persulfate into an aqueous solution with a mass concentration of 5%, and drop it within 1 hour, continue After reacting for 3 hours, the essence microcapsules were obtained by natural cooling.

Embodiment 2

[0031] Mix 50ml deionized water, 1.5g styrene, 5g rose essence and 0.75g TO7, and emulsify and disperse at a high speed at 15000 rpm for 10 minutes to obtain a fragrance emulsion containing styrene monomer; transfer the fragrance emulsion to a temperature of In a water bath at 90°C, pass in an inert protective gas, keep a mechanical stirrer at 1200 rpm, make 0.025g of potassium persulfate into an aqueous solution with a mass concentration of 0.5%, drop it within 2 hours, and continue the reaction for 4 hours. Essence microcapsules are obtained by natural cooling.

Embodiment 3

[0033] Mix 100ml deionized water, 3g styrene, 3g butyl methacrylate, 5g mint essence, 1g TO5 and 1.5g TO7, and emulsify and disperse at a high speed of 12000 rpm for 25 minutes to obtain butyl methacrylate and Essence emulsion of styrene monomer; transfer the essence emulsion to a water bath with a temperature of 70°C, pass through an inert protective gas, keep mechanical stirring at 1000 rpm, and prepare 0.45g of ammonium persulfate with a mass concentration of 2.5%. The aqueous solution is added dropwise within 1.5 hours, and the reaction is continued for 3.5 hours, and the essence microcapsules are obtained after natural cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com