Device integrating rice and wheat harvesting and straw carbonization and returning to field

A technology of carbonization of straw and harvesting of rice and wheat, which is applied in the direction of harvesters, cutters, special forms of dry distillation, etc., can solve the problems that straw carbonization cannot be widely popularized, and transportation costs increase the cost of carbon production, so as to reduce the environmental burden and save energy. Transportation cost, the effect of rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

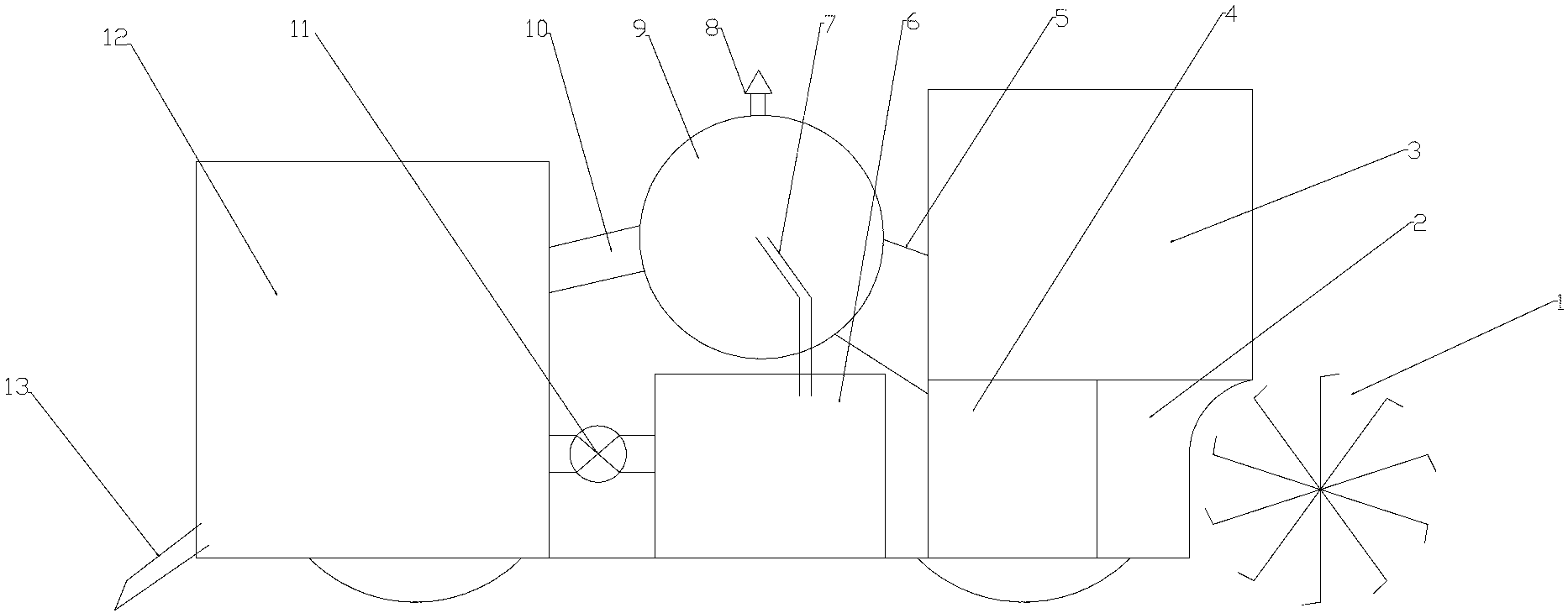

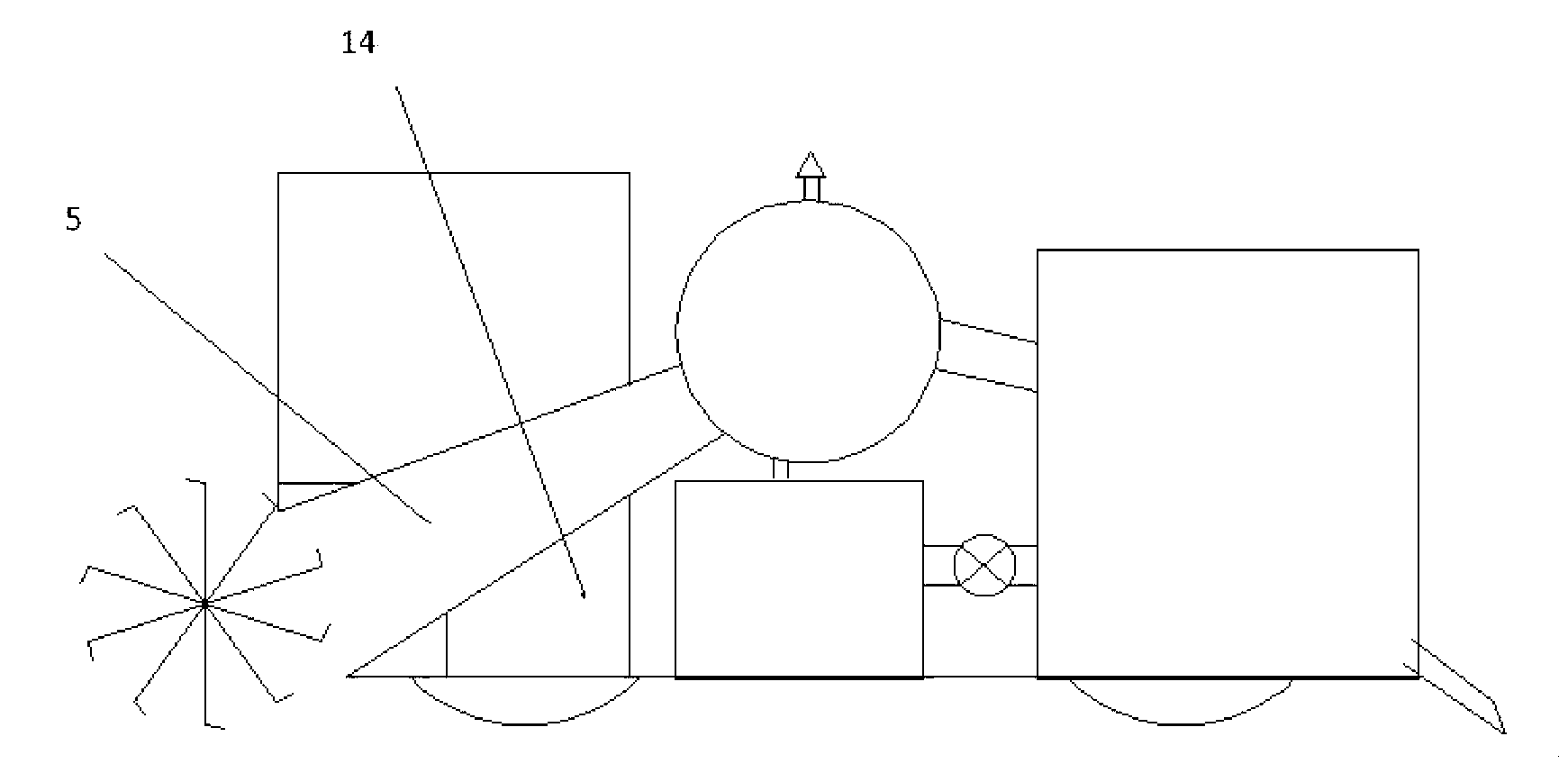

[0029] refer to Figure 1a ~ Figure 1b , the integrated device for rice and wheat harvesting and straw carbonization and returning to the field of the present invention includes a rice and wheat harvesting and threshing and straw cutting device, a straw carbonization and flue gas purification device; the rice and wheat harvesting and threshing and straw cutting device consists of harvesting platform 1 The feeding pipe 5 and the grain bin 14 are composed. The straw carbonization and flue gas purification device is composed of a rotary drying furnace 9 , a gas purification chamber 6 , a gas transmission pipe 7 , a chimney 8 , a feed pipe 10 , an induced draft fan 11 and a carbonization chamber 12 . The device is powered and driven by the fuel engine 2 and the engine 4, and the driver's cab 3 is for manual driving.

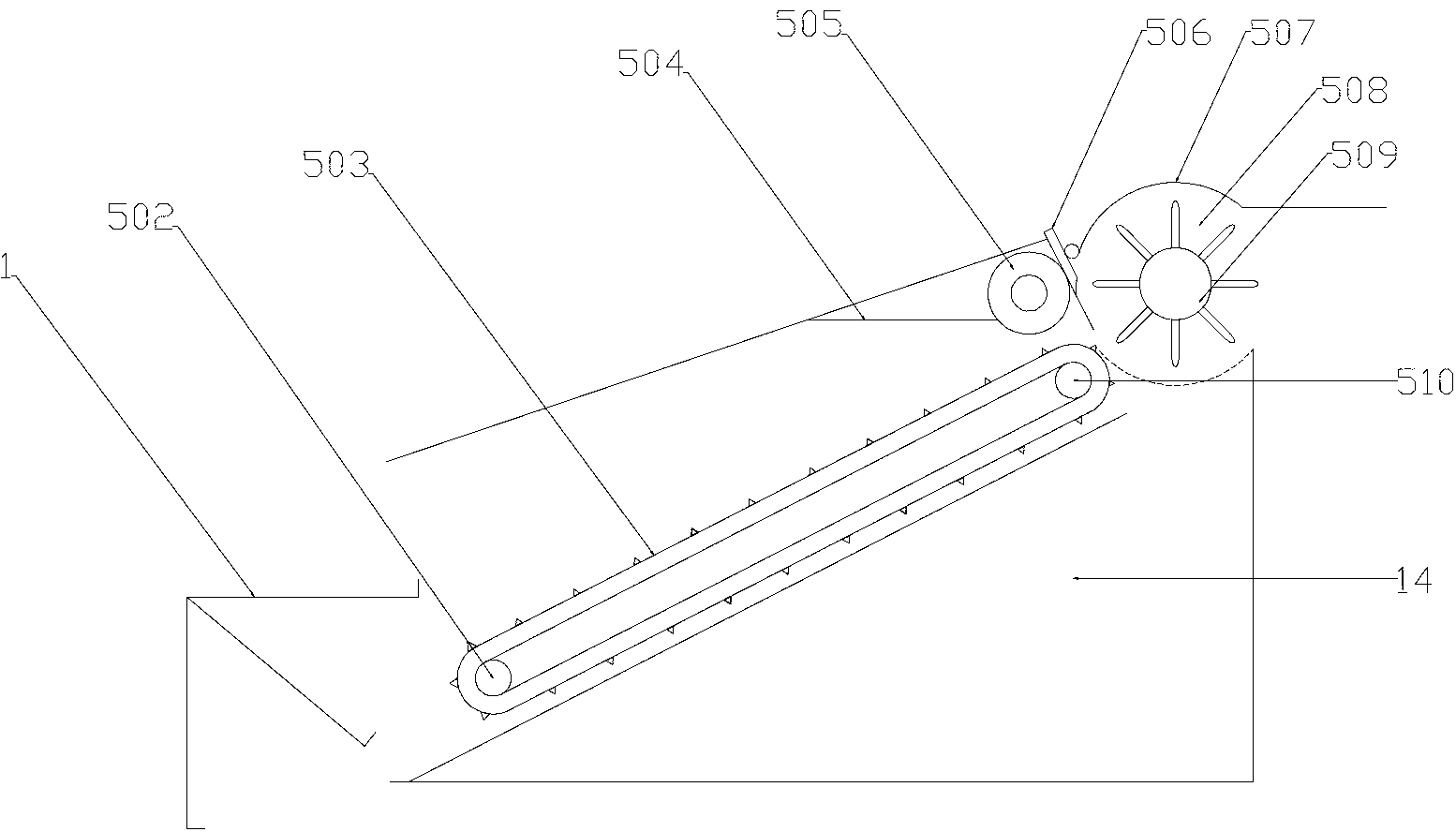

[0030] refer to figure 2 The rice and wheat harvesting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com