Carbonization device

A gas furnace and dryer technology, which is applied in special forms of dry distillation, petroleum industry, biofuels, etc., can solve the problems of lower combustion value, lower quality of carbon products, and low carbon production efficiency, and achieves improved heat transfer efficiency and raw materials. The effect of cost reduction and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

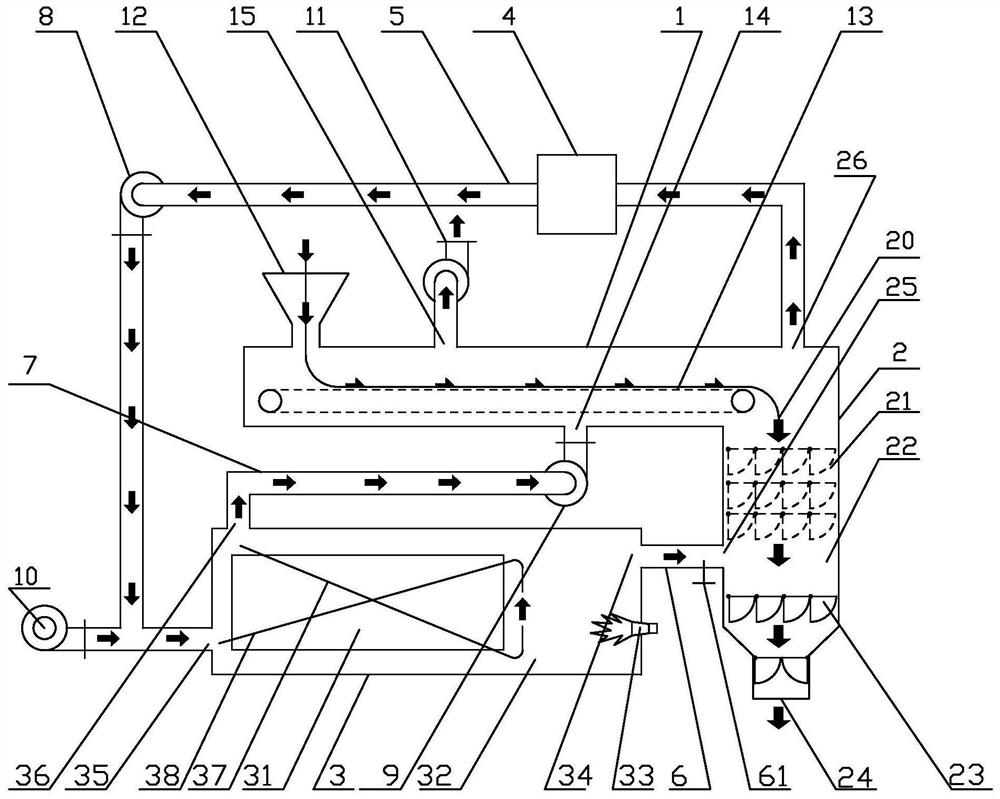

[0037] Embodiment 1: A kind of charcoal making device, comprises drier 1, pyrolysis furnace 2 and gas furnace 3; Described drier 1 is provided with feed inlet 12, low-temperature flue gas inlet 14 and tail gas outlet 15, so The dryer 1 described above is provided with a material conveying mechanism 13 inside; the top position of the pyrolysis furnace 2 is provided with a pyrolysis gas outlet 26, its upper position is provided with a material inlet 20, and its middle position is provided with a high-temperature smoke outlet. The gas receiving room 22 is provided with a discharge port 24 at its lower position; the pyrolysis furnace 2 is provided with a multi-layer breathable material down transmission mechanism 21 between the material inlet 20 and the high-temperature flue gas receiving room 22; A shutter 23 is provided between the high-temperature flue gas receiving room 22 and the discharge port 24; the gas furnace 3 is composed of a gas furnace heat exchanger 31 and a gas furn...

Embodiment 2

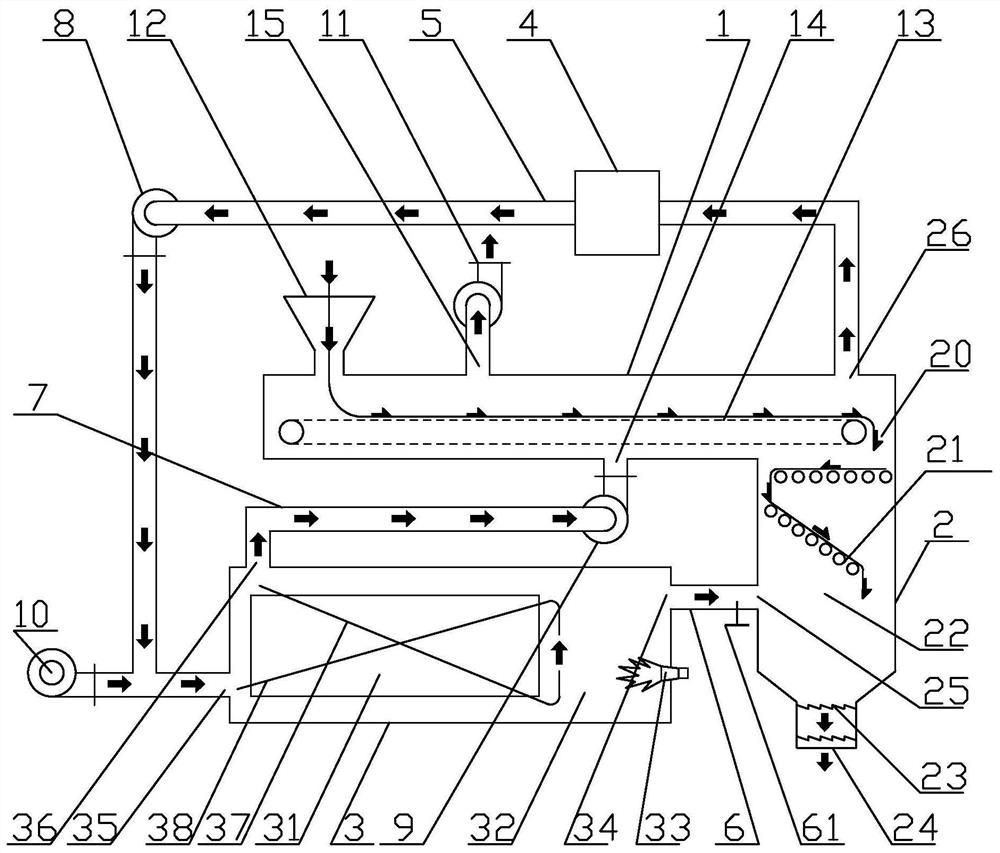

[0054] Embodiment 2: as figure 2 As shown, a charcoal making device includes a dryer 1, a pyrolysis furnace 2 and a gas furnace 3; the dryer 1 is provided with a feed inlet 12, a low-temperature flue gas inlet 14 and an exhaust gas outlet 15, and the The drying machine 1 is provided with a material conveying mechanism 13 inside; the top position of the pyrolysis furnace 2 is provided with a pyrolysis gas outlet 26, the upper position is provided with a material inlet 20, and the middle position is provided with a high-temperature flue gas The receiving room 22 is provided with a material outlet 24 at its lower position; the pyrolysis furnace 2 is provided with a multi-layer breathable material down-passing mechanism 21 between the material inlet 20 and the high-temperature flue gas receiving room 22; A shutter 23 is provided between the high-temperature flue gas receiving room 22 and the discharge port 24; the gas furnace 3 is composed of a gas furnace heat exchanger 31 and a...

Embodiment 3

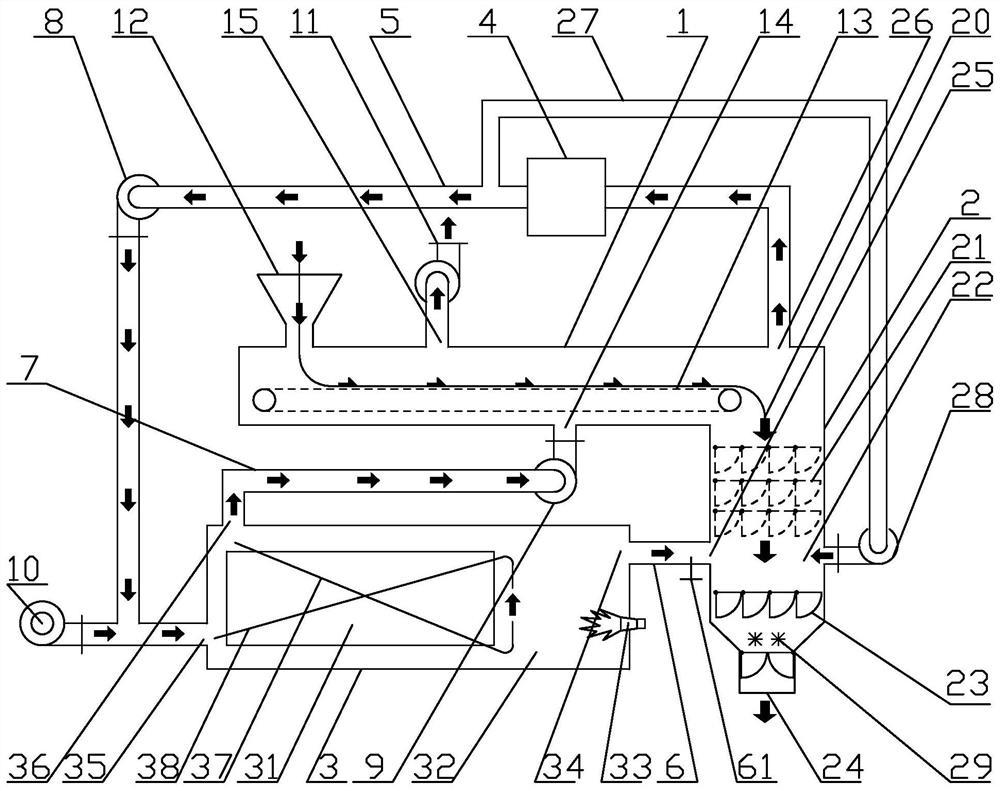

[0064] Embodiment 3: as image 3 , a charcoal production device, including a dryer 1, a pyrolysis furnace 2 and a gas furnace 3; Dryer 1 is provided with a material conveying mechanism 13 inside; the top position of the pyrolysis furnace 2 is provided with a pyrolysis gas outlet 26, the upper position is provided with a material inlet 20, and the middle position is provided with a high-temperature flue gas receiving room 22, its lower position is provided with a discharge port 24; the pyrolysis furnace 2 is provided with a multi-layer breathable material down transmission mechanism 21 between the feed port 20 and the high-temperature flue gas receiving room 22; the high-temperature A flashboard 23 is provided between the flue gas receiving room 22 and the discharge port 24; the gas furnace 3 is composed of a gas furnace heat exchanger 31 and a gas furnace hearth 32; One end is located in the hearth 32 of the gas furnace; the heat exchanger 31 of the gas furnace is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com