High efficiency, environmental protection and energy saving biomass carbon making unit

An environmental protection, energy saving, biomass technology, applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of pollution, poor labor environment, high labor intensity, etc., to reduce emission pollution, improve carbon production efficiency, and improve work efficiency The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] Such as Figure 1-5 shown.

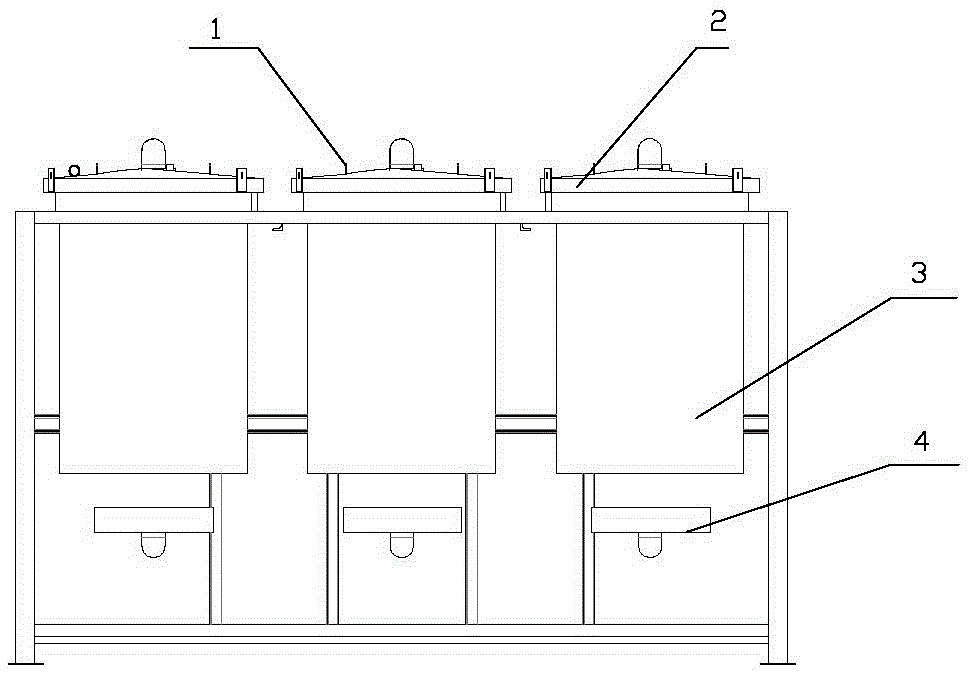

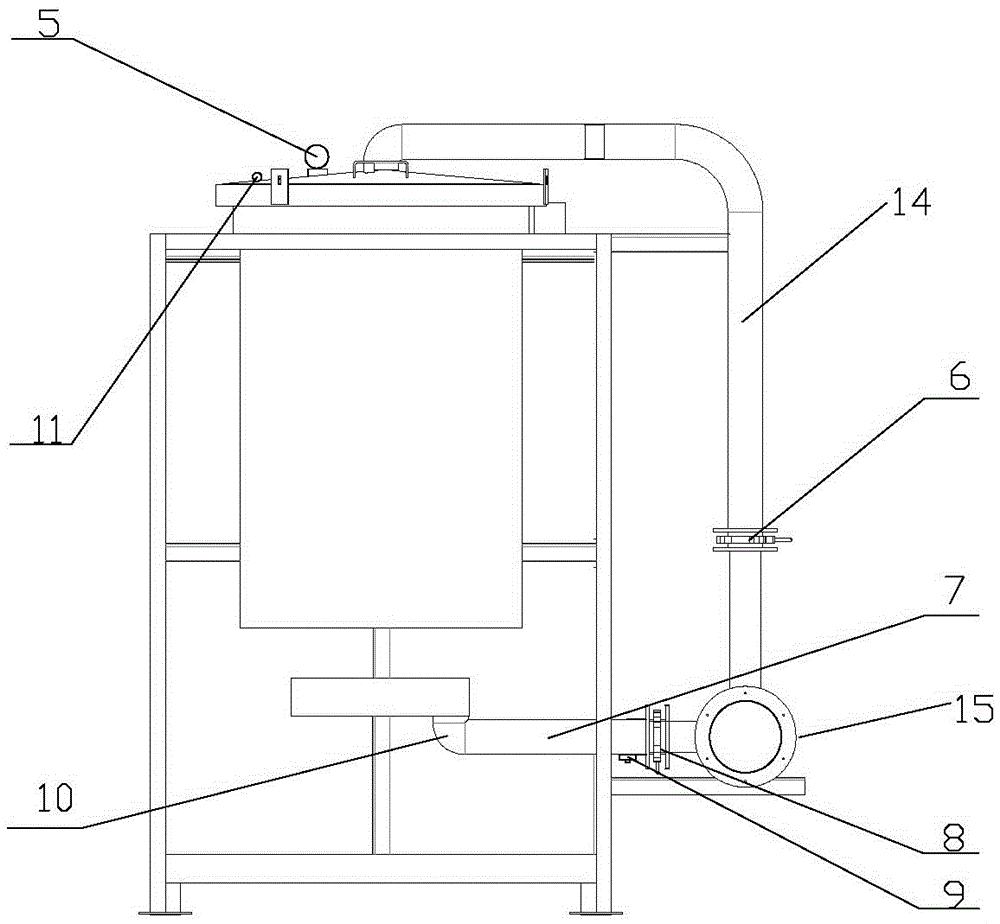

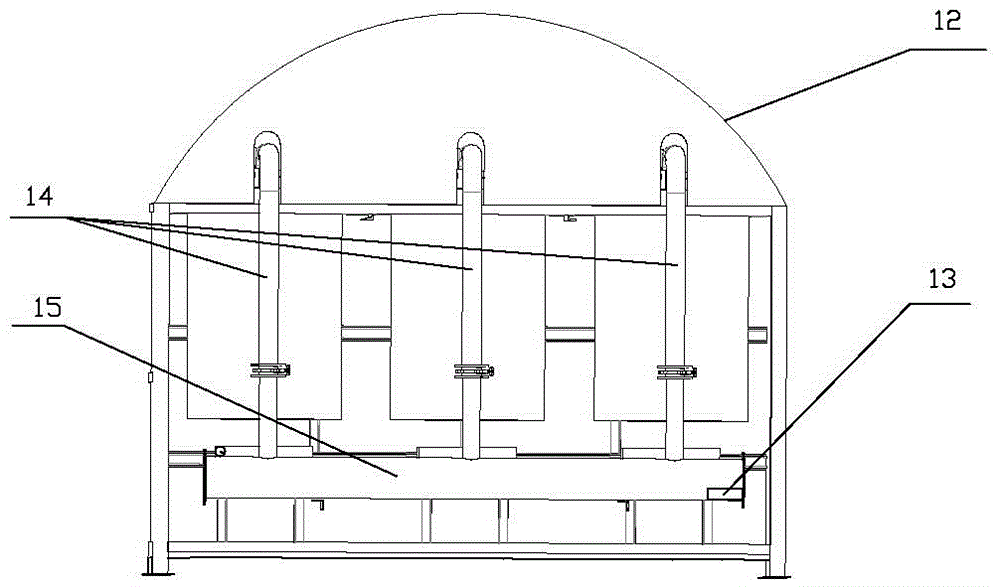

[0028] A high-efficiency environmental protection and energy-saving biomass carbon production unit, which includes three carbon kettles 3, and the three carbon kettles 3 are suspended and installed on the carbon kettle bracket 25, such as figure 1 , 3 , 5, the top of each carbon kettle 3 is provided with an upper end cover 2, a polyurethane heat insulation board 17 is installed between the upper end cover 2 and the carbon kettle body, and a pressure gauge 11 and a temperature indicator are installed on the upper end cover 2 5 and the handle 1 that is convenient to open, the bottom of each carbon kettle 3 is equipped with a burning tray 4, such as figure 2 As shown, the combustion disc 4 communicates with the pipeline 7 through the combustion disc interface 10, and the pipeline 7 communicates with the gas tank and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com