Combined ferrotitanium separator and application method thereof

A sorter, iron and titanium technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of many beneficiation processes, low screening accuracy, waste of raw materials, etc. Titanium precision, the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

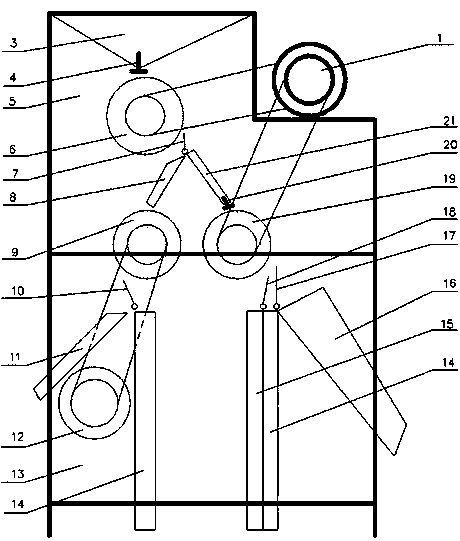

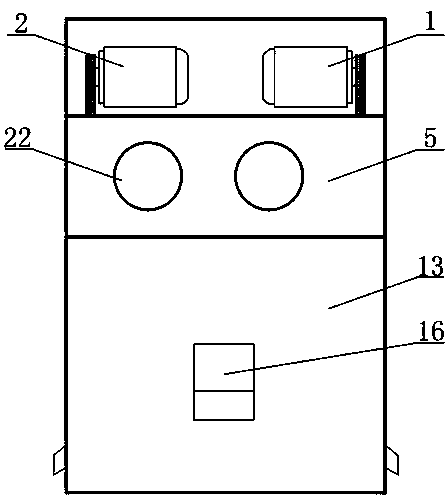

[0036] like figure 1 and figure 2 As shown, this combined ferro-titanium sorting machine includes an upper frame 5 and a lower base body 13 connected up and down, an iron-titanium sorting device located in the upper frame 5, and an iron-titanium sorting device located in the lower base body 13 and in the ferro-titanium separation unit. The medium-titanium sorting device and the refining device are arranged side by side under the selecting device, among which the iron-titanium sorting device, the medium-titanium sorting device and the refining device are arranged in a zigzag shape. In order to make the overall structure of the present invention compact, the upper frame is in the shape of an "L", the lower seat is in the shape of a cuboid, and is in the shape of a square frame "mouth" in side view. In order to clean the environment, a front end of the upper frame 5 is also provided There are two dust outlets 22. In actual operation, the dust outlet is connected with the dust e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com