Electrochemical treatment device for sewage and wastewater treatment

A treatment equipment, electrochemical technology, applied in the field of resources and environment, can solve the problems of plate installation limitations, increase operating costs, equipment failure, etc., to optimize the water distribution adjustment function, improve equipment reliability, and reduce equipment damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

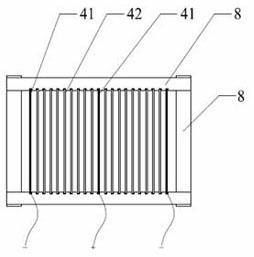

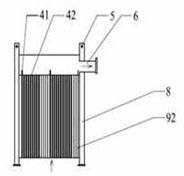

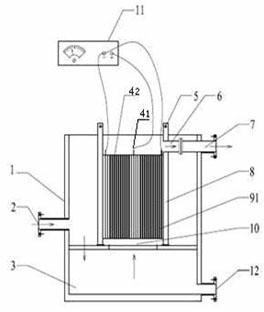

[0031] like figure 1 , figure 2 and image 3 As shown, the electrochemical treatment equipment includes a reaction tank 1 and electrochemical reaction modules 91, 92; the reaction tank 1 is provided with a water inlet 2, a water distribution area 3, a water outlet 7 and a reaction tank vent pipe 12; the electrochemical reaction module 91, 92 includes a cubic support structure 8, and several inert pole plates 41 and soluble pole plates 42 are arranged at intervals in the support structure 8 (according to the difference of the water quality to be treated, the setting ratio of the iron pole plate and the aluminum pole plate in the soluble pole plate 42 is 2 : 8~9: 1), the inert plate 41 is connected to the power supply 11; the bottom of the support structure 8 is provided with an opening 10, and the bottom opening 10 communicates with the water distribution area 3 of the reaction tank 1; the support structure 8 is provided with a top water outlet 6 , the top water outlet 6 and...

Embodiment 2

[0034] Using simulated experimental wastewater to study, the treatment effects of mixed plates and single plates, and the consumption of plates were studied.

[0035] The main heavy metal factors of simulated experimental wastewater are Cu, Zn and hexavalent chromium. The concentration of the prepared raw water is shown in Table 1.

[0036] Table 1 Simulation experiment wastewater quality (unit: mg / L)

[0037]

[0038]The simulated waste water is treated by the invention, and the plate consumption and treatment effect under two working conditions of a mixed plate and a single plate are mainly studied. The basic parameters of the electrochemical treatment equipment are as follows: the distance between the plates is 3cm, and the voltage and current vary with different working conditions; the treatment process is as follows: firstly adjust the pH value and conductivity of the simulated wastewater for pretreatment, and then use the present invention to treat the wastewater For...

Embodiment 3

[0047] Embodiment 3 Effect experiment of the electrochemical treatment equipment of the present invention on sewage treatment

[0048] Taking a certain lead-zinc smelting wastewater from non-ferrous smelting as the treatment object:

[0049] The main pollution components of the wastewater are Pb, Cd, Zn, As, with high concentration of heavy metal pollutants and high acidity. The waste water is treated by the present invention. The basic parameters of the electrochemical device are as follows: constant current density 144.6A / m 2 , the distance between the pole plates is 3cm, and the continuous and stable operation is 30 days (the pole plates are not replaced during the period); under this parameter, the treatment process is as follows: firstly adjust the pH value of the waste water to about 7 for pretreatment, and then use the present invention to treat the waste water and treat the raw water And the treated effluent was detected and analyzed by atomic absorption instrument, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com