C<2->/C<3+> light dydrocarbon separation method integrating absorption method with fractionation method and C<2->/C<3+> light dydrocarbon separation system

A technology of fractionation and absorption, which is applied in the separation of C2/C3 light hydrocarbons, can solve the problems of lower relative volatility and consume more energy, and achieve the effect of reducing energy consumption of separation and increasing relative volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

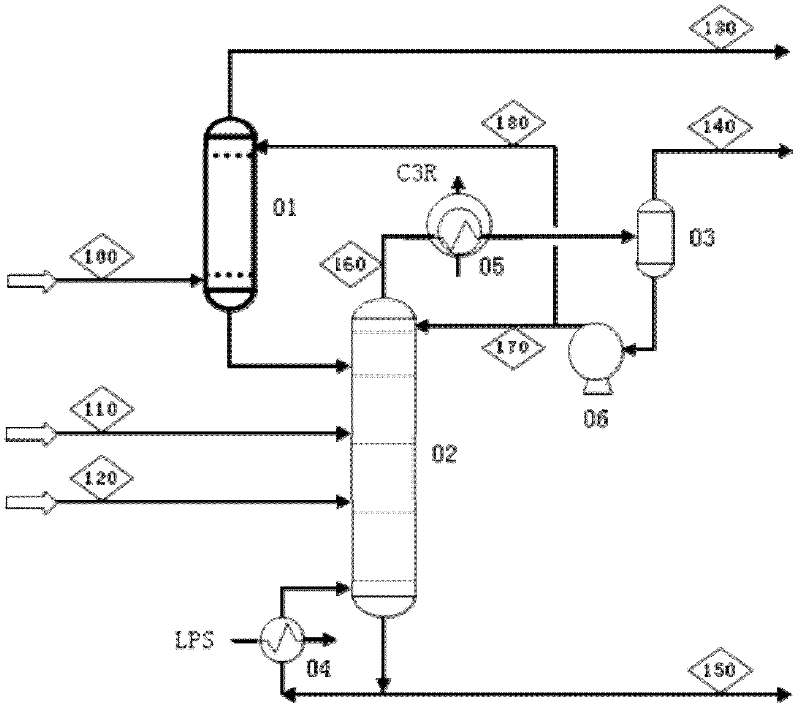

[0037] Embodiment 1 Absorption tower integrated with high-pressure deethanizer tower

[0038] The feed gas and two streams of feed liquid formed after multi-stage pressurization, cooling and condensation, gas-liquid separation, deacidification, and dehydration in the upstream enter the C3 absorption tower 01 and the deethanizer 02 respectively (the three feeds The material is obtained from the upstream system, figure 1 The formation process of the three feeds is not shown, and the use of multiple feeds is one of the common practices in the existing fractionation process)

[0039] like figure 1 As shown, the feed gas first enters the C3 absorption tower 01. The C3 absorption tower 01 is a tower with a simple structure, which is equipped with trays or packing equivalent to about 10 theoretical plates. In the C3 absorber 01, the feed gas is counter-contacted with the absorbent from the deethanizer reflux pump 06 (ie "lean liquor"). The easily soluble component in the feed, i.e...

Embodiment 2

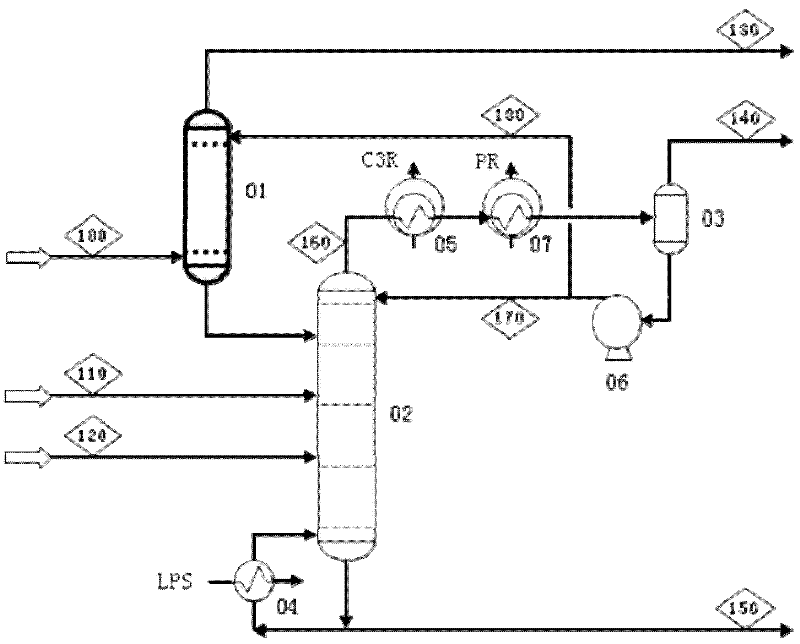

[0046] Embodiment 2 Absorption tower integrated with low-pressure deethanizer

[0047] The feed gas and two streams of feed liquid formed after multi-stage pressurization, cooling and condensation, gas-liquid separation, deacidification, and dehydration in the upstream enter the C3 absorption tower 01 and the deethanizer 02 respectively (the three feeds The material is obtained from the upstream system, figure 2 The formation process of the three feeds is not shown, and the use of multiple feeds is one of the common practices in the existing fractionation process).

[0048] like figure 2 As shown, the feed gas first enters the C3 absorption tower 01. C3 absorption tower 01 is a tower with a simple structure, which is equipped with trays or packing equivalent to about 10 theoretical plates. In the C3 absorber 01, the feed gas is counter-contacted with the absorbent from the deethanizer reflux pump 06 (ie "lean liquor"). The easily soluble component in the feed, i.e. almos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com