Monolithic catalyst reactor and application of monolithic catalyst reactor to synthesis gas preparation through natural gas reforming

A reactor and catalyst technology, applied in the field of catalyst reactors with integral structure, can solve the problems of poor heat transfer, not many catalytic reactors, and decreased reaction activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

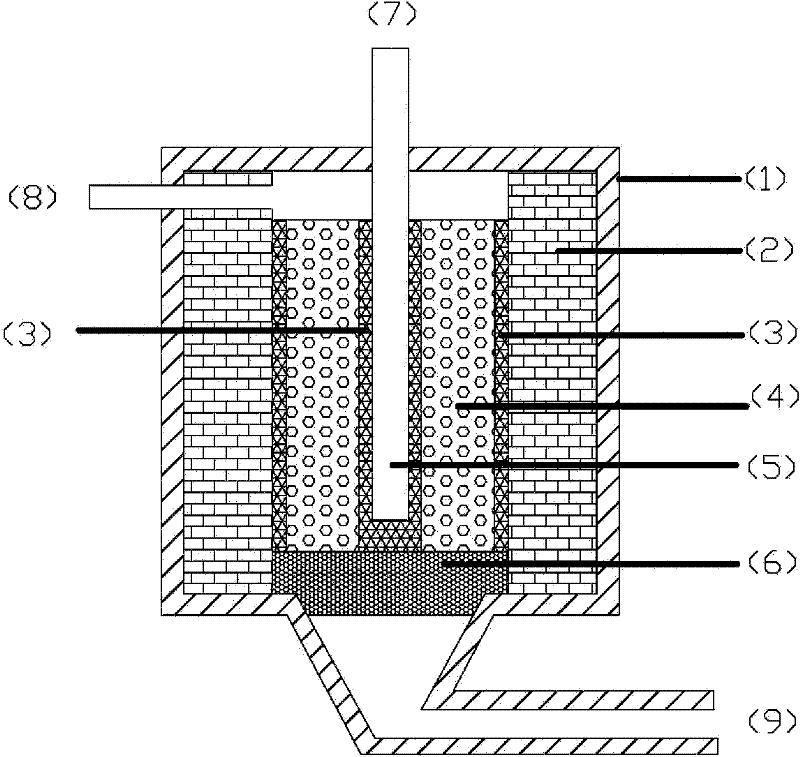

[0016] A catalyst reactor with a monolithic structure, which is a stainless steel reactor lined with a high-temperature ceramic casting insulation layer and adopts a monolithic catalyst as the main catalyst;

[0017] The reactor is provided with a monolithic catalyst. The monolithic catalyst is a barrel-shaped structure with a bottom at the bottom and an open upper end, that is, there is a channel structure for placing an oxygen distributor in the middle, and the oxygen distributor extends into the barrel-shaped monolithic catalyst;

[0018] Between the monolithic catalyst and the reactor, the reactor and the oxygen distributor is filled with particulate catalyst as the secondary catalyst;

[0019] The monolithic catalyst is made of monolithic foamed silicon carbide or honeycomb cordierite as the carrier, supporting Ni metal, and the content of the metal active component is 20wt%; the particle catalyst is obtained by supporting the metal in Rh on spinel, and the metal activity The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com