Carbonization-activation integrated activated carbon production apparatus

An integrated activated carbon production technology, applied in carbon compounds, inorganic chemistry, chemical industry, etc., can solve the problems of poor product absorption, high coal consumption, long reaction time, etc., and achieve the effect of improving stability and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

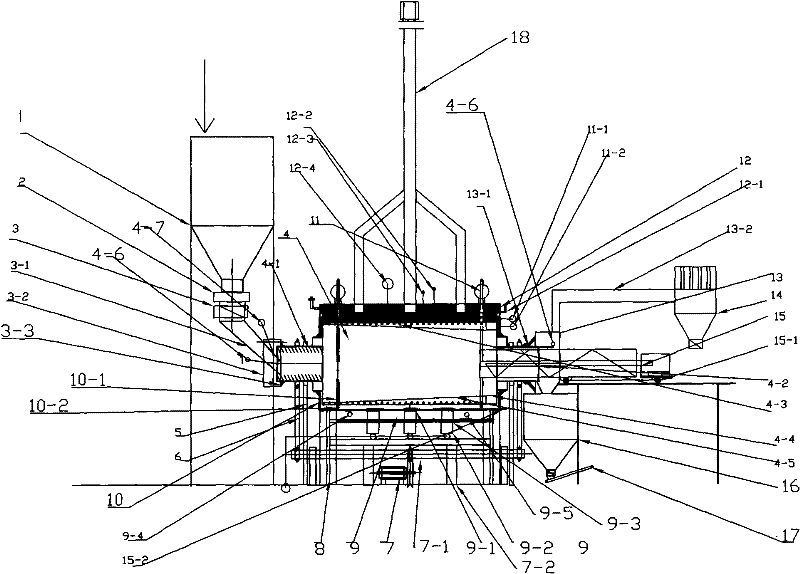

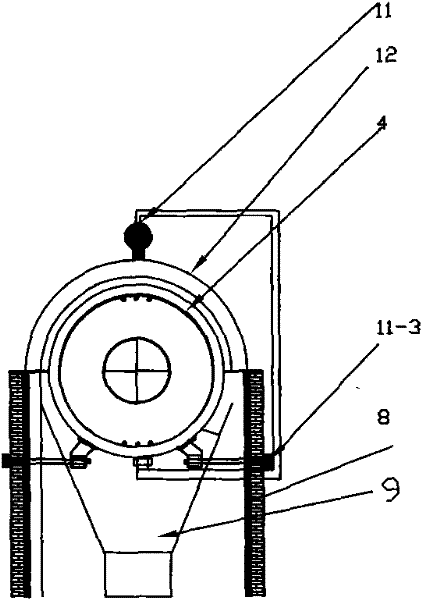

[0009] 4. The carbonization and activation integrated activated carbon production device proposed by the present invention is characterized in that figure 1 figure 2 As shown, the dried raw carbon strips and pellets enter the silo 1, are measured by the weighing scale 2 at the bottom of the silo, pass through the gate valve 3, enter the chute 3-1, and then pass through the material guide plate in the hollow shaft of the rotary kiln. The material is quickly introduced into the rotary kiln 4; 3-2 is the rotary kiln hood fixed on the chute, 3-3 is the flexible seal on the hood and the hollow shaft at one end of the rotary kiln, 4 is the rotary kiln, 4-1 is The hollow shaft at the head of the rotary kiln, 4-2 is the hollow shaft at the tail of the rotary kiln, and 4-3 is a plurality of intake caps, which is characterized in that the main shell of the rotary kiln is designed with a plurality of φ30 small holes, and the hole spacing is 100 to 300 square meters The hole is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com