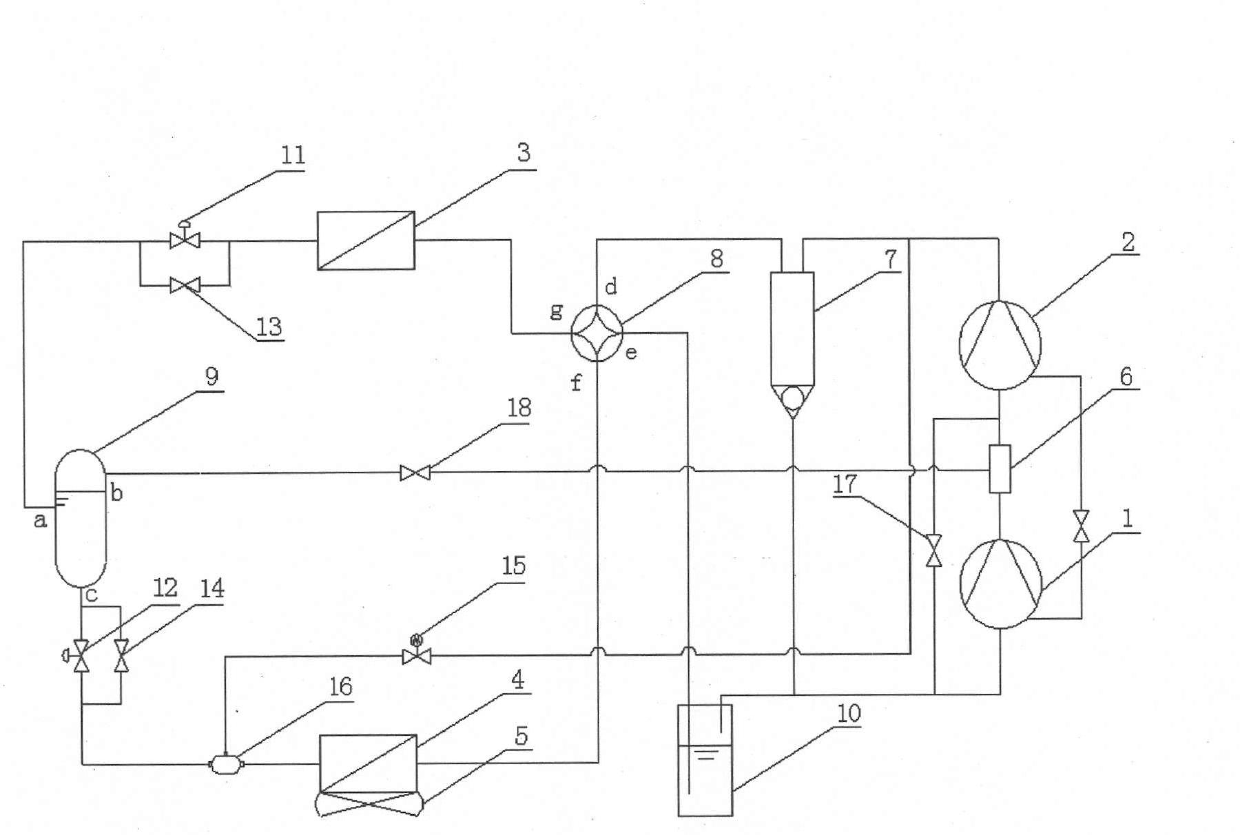

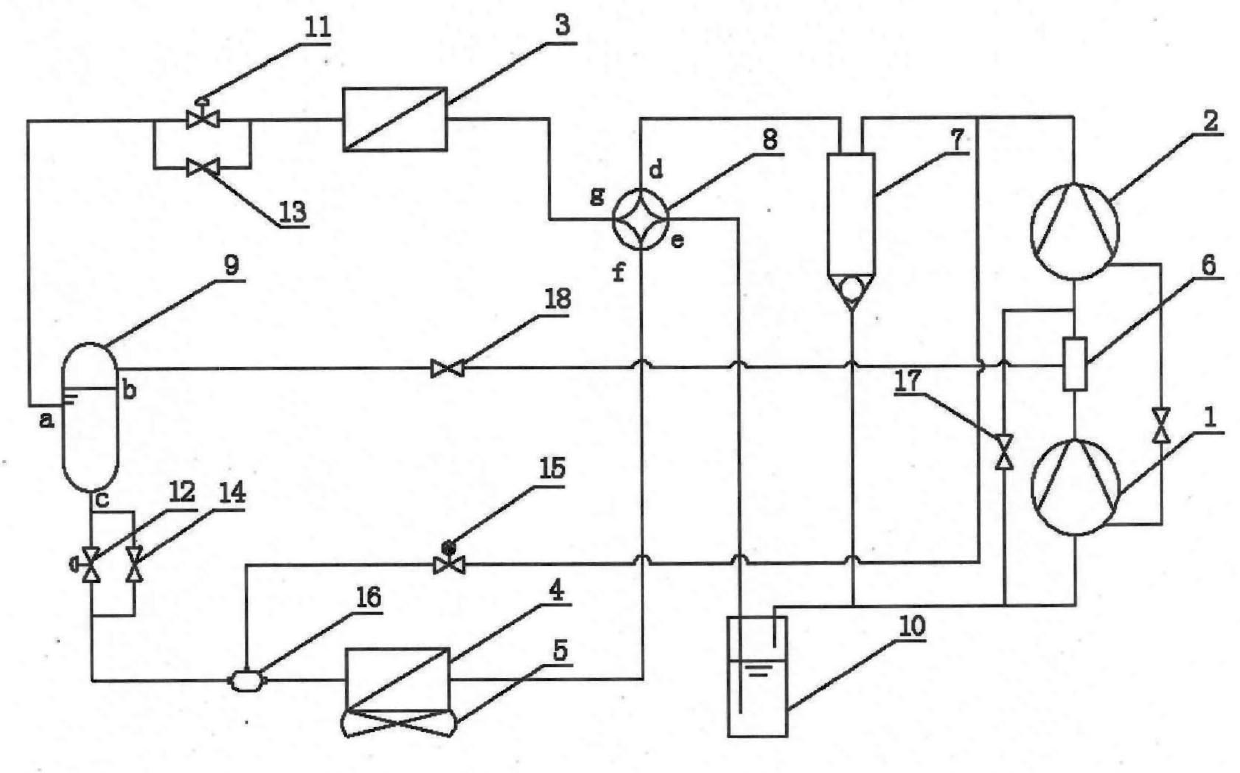

Twin-stage compression heat pump system with hot gas bypass defrosting device

A hot gas bypass defrosting and two-stage compression technology, which is applied in the field of air-conditioning heat pumps, can solve problems such as high exhaust temperature of the compressor, frequent start and stop of the system, and failure to work normally, so as to reduce the exhaust temperature and shorten the defrosting time , reliable long-term operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0016] Such as figure 1 As shown, the two-stage compression heat pump system with a hot gas bypass defrosting device disclosed in this embodiment includes a low-pressure compressor 1, and the exhaust port of the low-pressure compressor 1 communicates with the suction port of the high-pressure compressor 2 through the mixing chamber 6 , the inlet port of the low-pressure compressor 1 communicates with the inlet port of the high-pressure compressor 2 through the third shut-off valve 17, and the exhaust port of the high-pressure compressor 2 passes through the oil separator 7 and the four-way reversing valve 8 to communicate with the refrigerant / The water heat exchanger 3, the refrigerant / water heat exchanger 3 communicates with a port a of the liquid and gas-liquid mixed refrigerant channel of the intercooler 9 through the electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com