Industrial circulating seawater aquiculture system

A recirculating aquaculture and industrial technology, applied in fish farming, application, animal husbandry and other directions, can solve the problems of limited scale application, high cost, marine environmental pollution, etc., to reduce adverse effects, less water treatment equipment, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

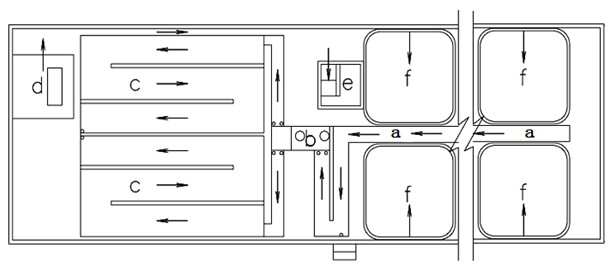

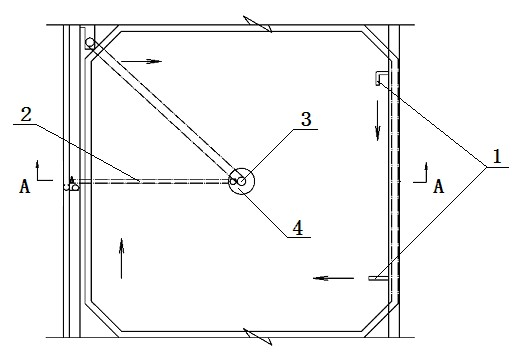

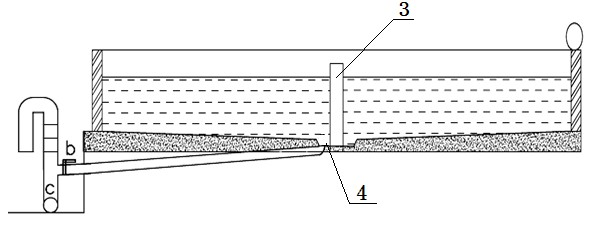

[0026] The seawater industrialized recirculating aquaculture system of this embodiment includes a culture pond, a residual bait and feces separation system sequentially connected to the culture pond through pipelines, an air flotation system for further separating solid microparticle residues in the water body, and an air flotation system for removing organic matter in the water body. The buried biological water treatment system for pollutants, the ground source heat pump system for regulating the temperature of the water body, the high-level pool for disinfecting the water body, and the aeration and oxygenation system for supplementing the water body in the breeding pond;

[0027] The residual bait and feces separation system includes a flushing pipe 1 that extends into the bottom of the breeding pond, a residual bait and feces collection channel 2 that communicates with the sewage outlet 4 of the breeding pond, and a central pipe 3 that extends into the breeding pond to discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com