Difunctional visual light responding catalyst, and preparation method and application thereof

A photocatalyst and catalyst technology, applied in the field of photocatalytic materials, can solve the problems of performance research limitations, poor activity and stability, etc., and achieve the effects of strong visible light response, high activity and stability, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of nano photocatalyst AgAgCl with strong visible light absorption

[0038]Add 108 mg of polyvinylpyrrolidone and 22 mg of sodium chloride into a 50 mL round-bottomed flask containing 15 mL of glycerol, dissolve in a 60°C oil bath with magnetic stirring, and then quickly inject 1 mL of silver nitrate in glycerine Alcohol solution (52 mg / mL), and increase the magnetic stirring speed to react at 60°C for 1 h; then raise the temperature to 220°C for 10 min. After the reaction was completed, the round-bottomed flask was taken out and naturally cooled to room temperature, centrifuged and washed with deionized water to obtain the AgAgCl visible light catalyst.

[0039] The XPS analysis (X-ray photoelectron spectroscopy) result of the obtained catalyst showed that the mass fraction of silver was 10.2%.

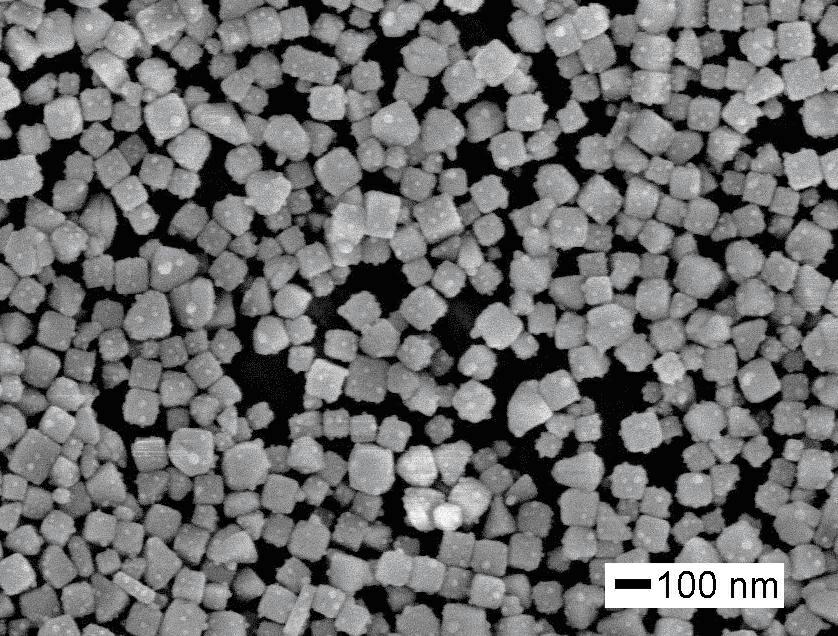

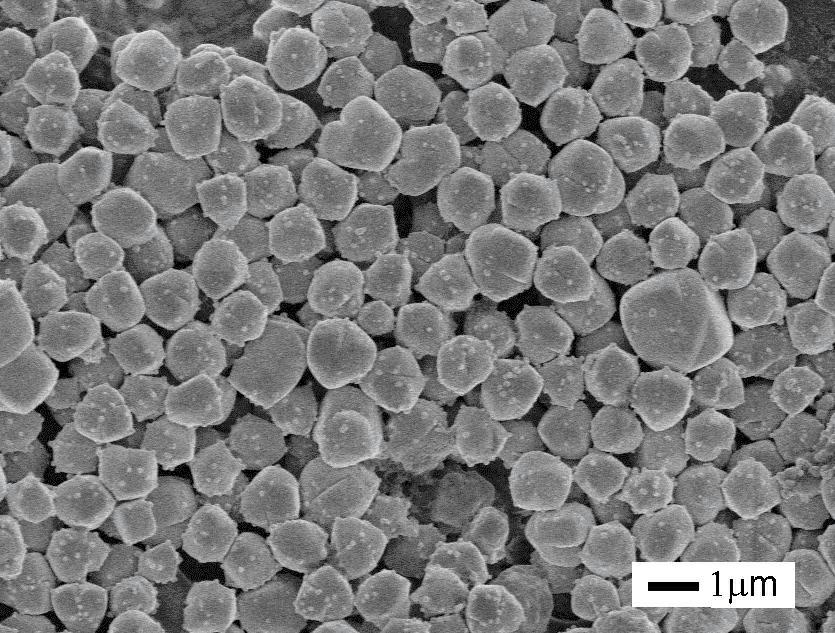

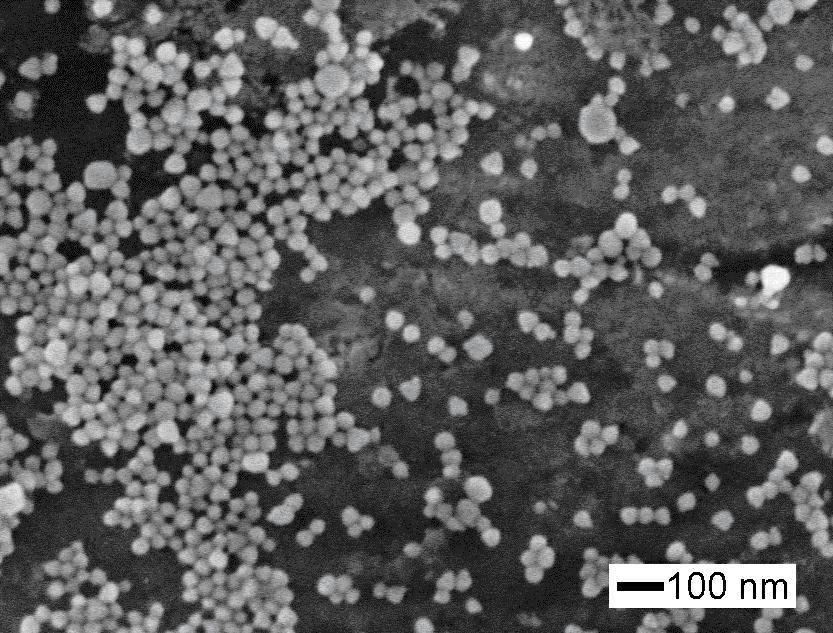

[0040] Picture 1-1 with Figure 1-2 Be respectively the scanning electron microscope (SEM) picture of the AgCl synthesized in embodiment 1 and the visible light ...

Embodiment 2

[0042] Preparation of nano photocatalyst AgAgCl with strong visible light absorption:

[0043] Add 150 mg of polyvinylpyrrolidone and 35 mg of sodium chloride into a 50 mL round-bottomed flask containing 15 mL of glycerol, dissolve with magnetic stirring in an oil bath at 60°C, and then rapidly inject 1 mL of silver nitrate in glycerine Alcohol solution (52 mg / mL), and increase the magnetic stirring speed at 60 ° C for 1 h; then raise the temperature to 220 ° C for 20 min. After the reaction was completed, the round-bottomed flask was taken out and naturally cooled to room temperature, centrifuged and washed with deionized water to obtain the AgAgCl visible light catalyst.

[0044] The result of XPS analysis (X-ray photoelectron spectroscopy) of the obtained catalyst showed that the mass fraction of silver was 15.1%.

Embodiment 3

[0046] Visible light-responsive catalyst AgAgCl with surface plasmon effect for CO reduction 2 performance:

[0047] The obtained AgAgCl catalyst was dispersed in 50 mL of sodium bicarbonate solution (0.1 mol / L), and CO was introduced at a rate of 0.7 L / min. 2 Gas for 10 minutes to remove the air in the reactor, and then under magnetic stirring, use a 300W xenon lamp (with an ultraviolet filter) as a visible light source, and the distance between the light source and the liquid surface is 25 cm, and perform a reduction reaction experiment. After 5 hours of reaction, centrifuge Take out the supernatant, conduct qualitative analysis with gas chromatography-mass spectrometry, and then determine the content of the product with gas chromatography. Then the catalyst was recovered, washed twice with deionized water, and then the cycle reaction experiment was carried out according to the above steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com