FRP sleeve processing method, processing device and drill bit

Technology of a processing device and processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

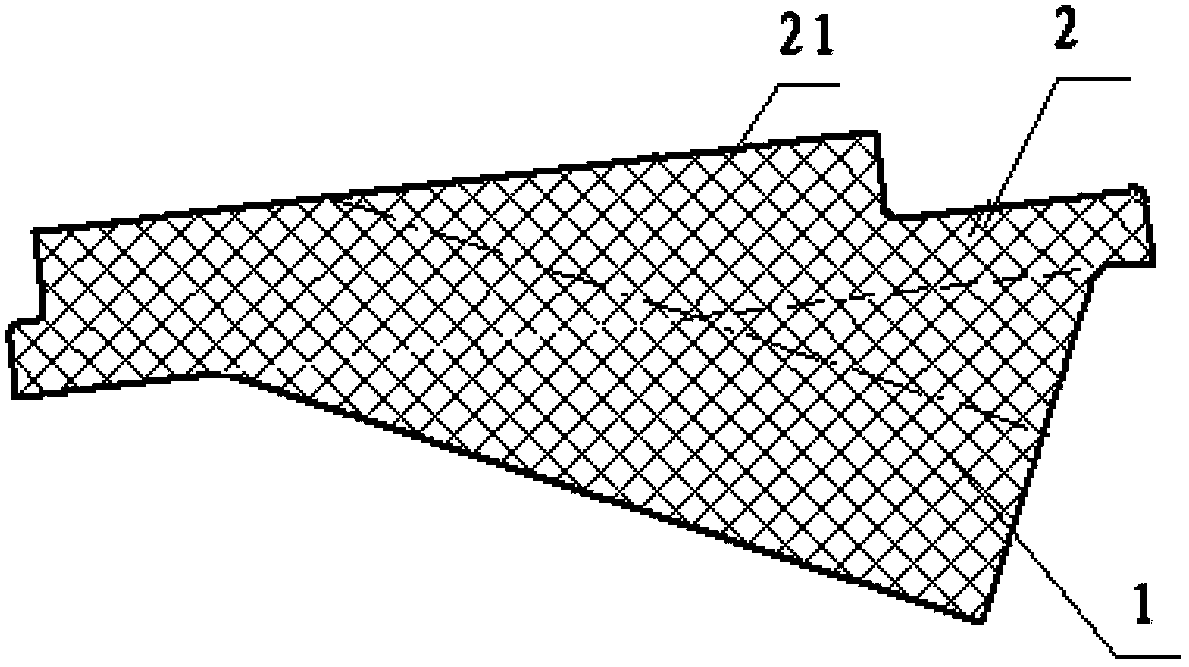

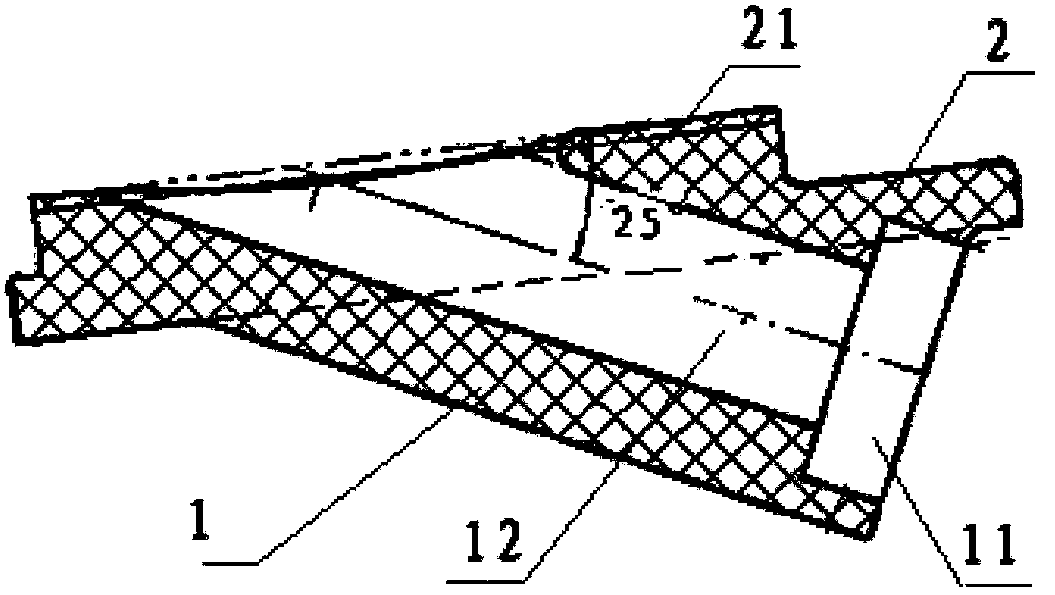

[0026] will be like figure 1 Shown a glass fiber reinforced plastic sleeve blank (comprising glass fiber reinforced plastic sleeve main body 1 and fixed plate 2, there is protrusion 21 at the bottom of fixed plate 2) processed into such as figure 2 In the shown FRP sleeve, the central hole includes a coaxial stepped hole 11 and an inner hole 12. The coaxiality of the two holes is 0.08mm, of which the stepped hole is 11φ42mm, 13.5mm deep, and the inner hole is 12φ26mm, 130mm deep. The axis of the center hole of the fiberglass sleeve intersects the upper plane of the fixed plate 2 to form an acute angle, and the angle is 25°.

[0027] The processing steps of the processing method that the present embodiment adopts are as follows:

[0028] Center hole positioning, draw the cross center line of the center hole in the center of the main body 1 of the FRP sleeve;

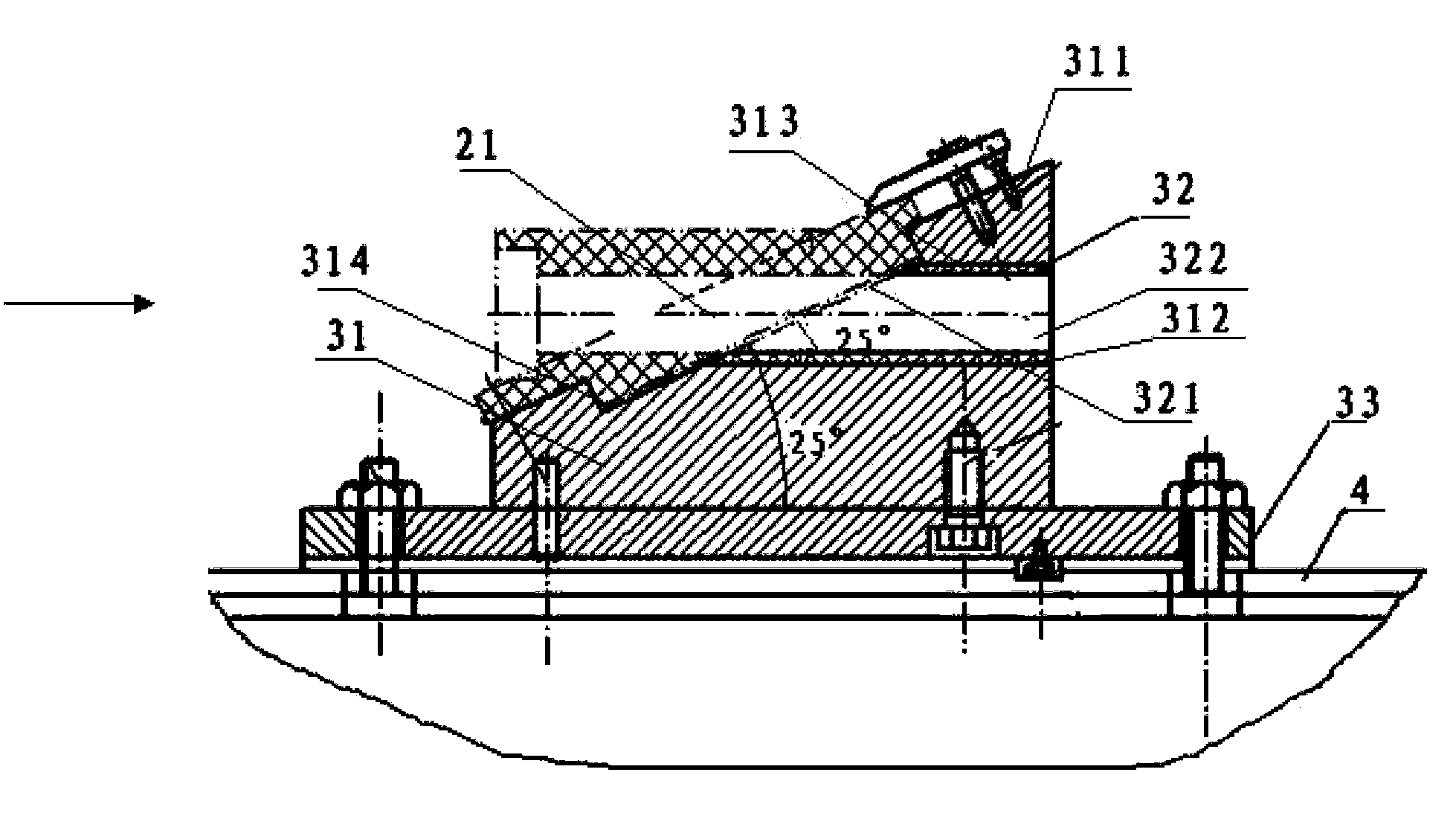

[0029] Fixed FRP sleeve blanks, such as image 3 As shown, the fiberglass sleeve blank is installed on the boring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com