Method for preparing zinc oxide micro-nano tooth-shaped rods and zinc oxide micro-nano pine cones

A zinc oxide, micro-nano technology, applied in the field of preparation of micro-nano zinc oxide, can solve the problems of high cost, high reaction temperature, complex equipment, etc., and achieve the effects of pure crystallization, simple operation and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

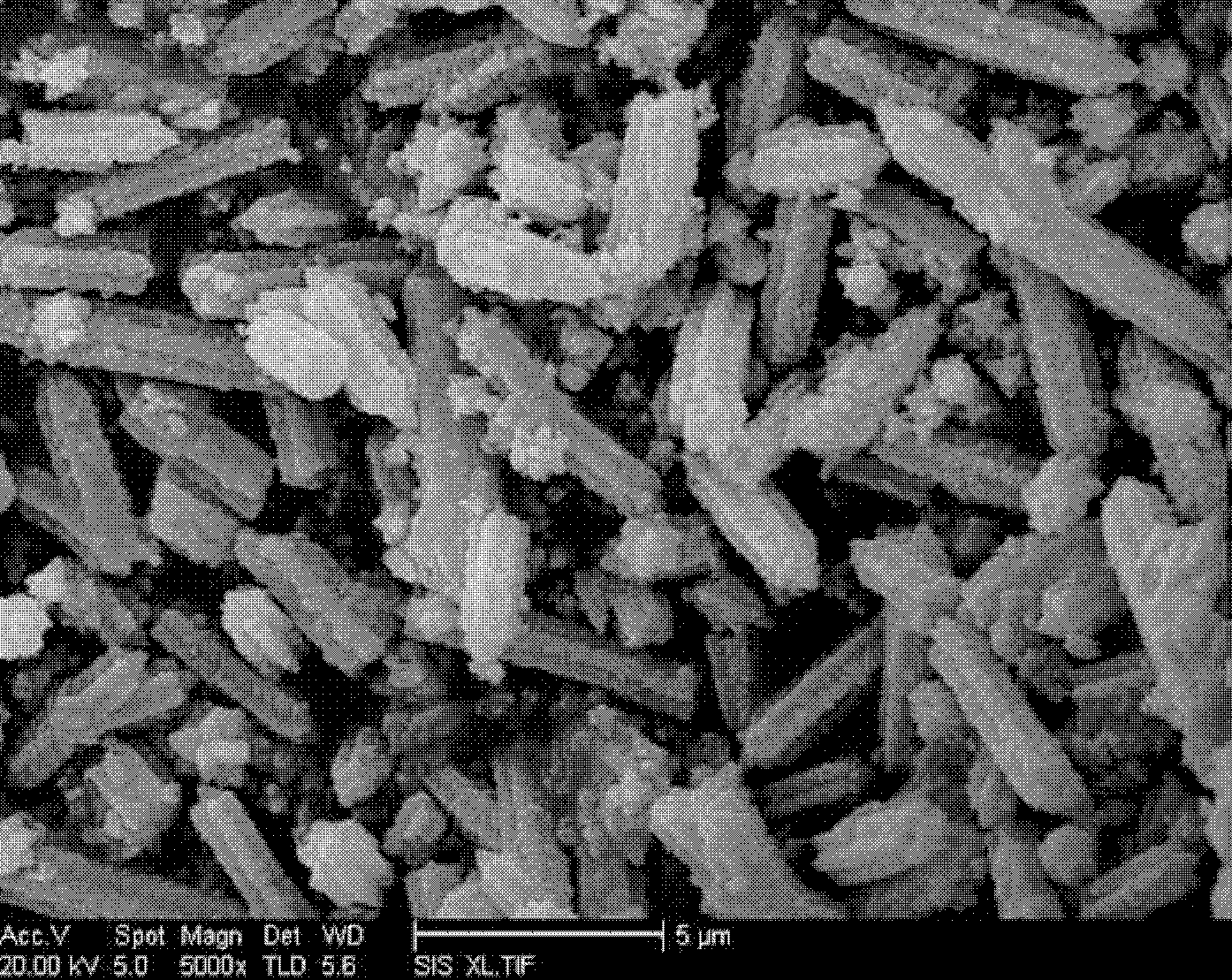

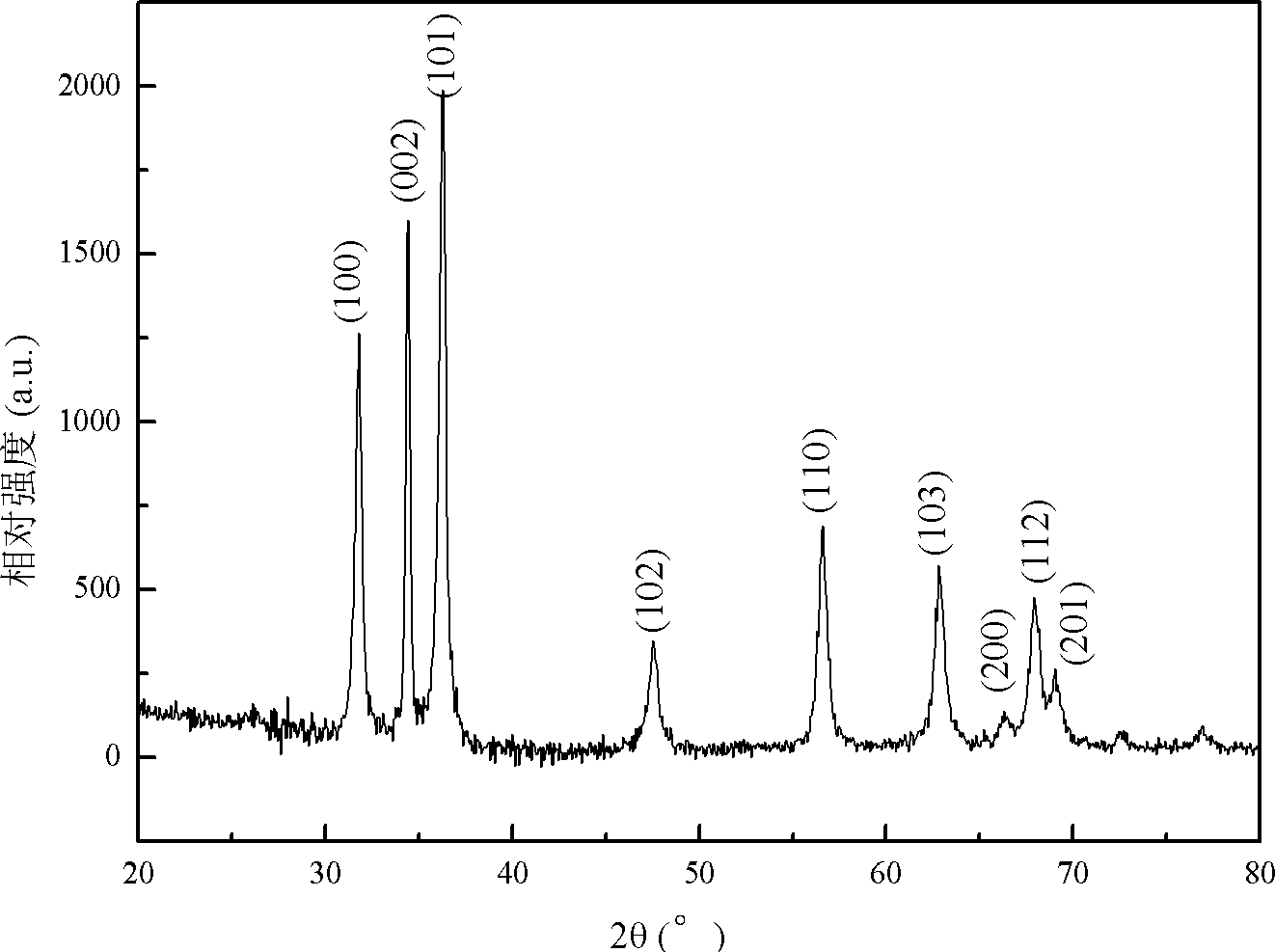

[0019] Specific embodiment one: the method for preparing zinc oxide micro-nano toothed rods in this embodiment is as follows:

[0020] Step 1: Slowly add 25ml of an aqueous solution of zinc nitrate hexahydrate with a concentration of 0.06mol / L to 25ml of an aqueous solution of hexamethylenetetramine with a concentration of 0.06mol / L, stir while adding, and then add 25ml of a concentration of Be the sodium hydroxide aqueous solution of 1.5mol / L, obtain mixed solution;

[0021] Step 2: Stir the mixed solution on a magnetic stirrer at a speed of 300 rpm for 3 to 5 minutes to obtain a transparent and clear solution;

[0022] Step 3: Pour the clarified solution into a stainless steel reaction kettle lined with polytetrafluoroethylene, then place the reaction kettle in a vacuum drying oven at 120°C, keep it warm for 14-18 hours, then take out the reaction kettle and air-cool it at room temperature for 1 hour , take out the clear solution, add distilled water to dilute according to ...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that the holding time in step 3 is 15 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment is different from Embodiment 1 in that the holding time in step 3 is 16 hours. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com