Separated anaerobic baffled reactor and work method of separated anaerobic baffled reactor

An anaerobic deflection and working method technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of difficult control of dominant bacterial species, achieve the effects of no need for mechanical mixing devices, low sludge yield, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

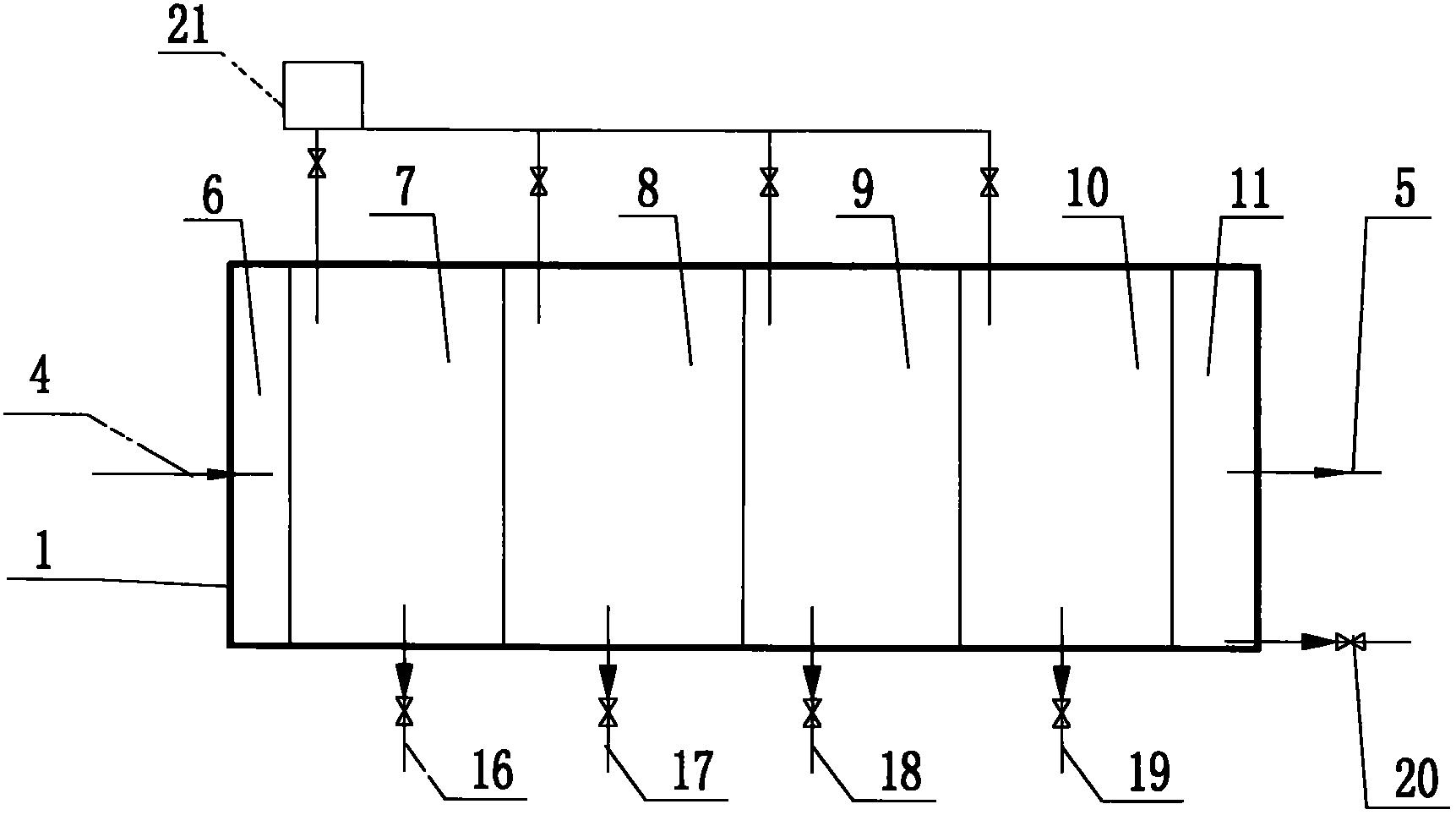

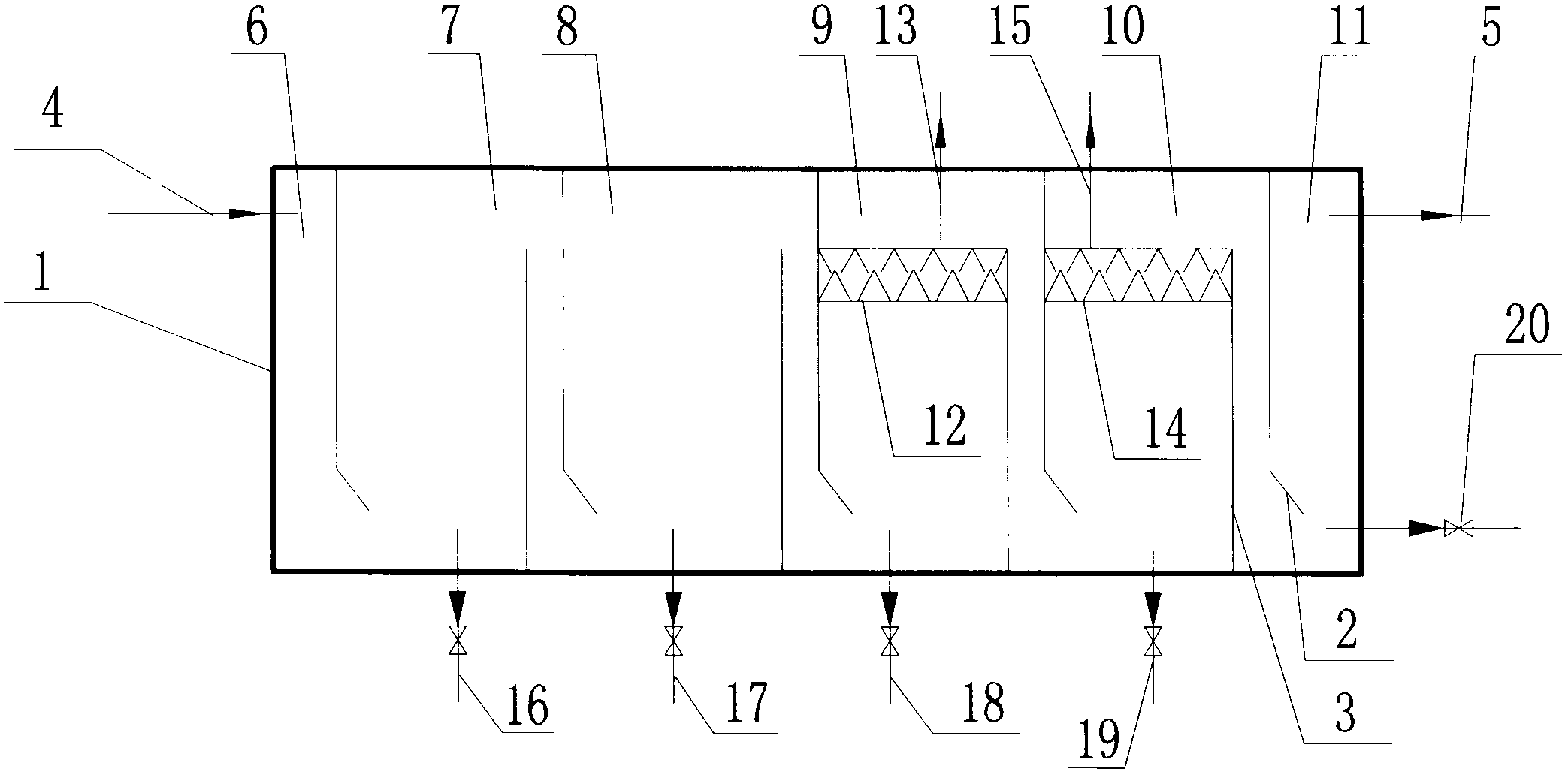

[0059] Such as Figure 2 to Figure 3 Schematically shows a separate anaerobic baffle reactor according to an embodiment of the present invention, which includes a reactor body 1 , a controller 21 , several upper baffles 2 and several lower baffles 3 . The upper baffle 2 is vertically fixed on the top of the reactor body 1, the lower baffle 3 is vertically fixed on the bottom of the reactor body 1, and the bottom of the upper baffle 2 is provided with a knuckle along the water flow direction. The two ends of the reactor body 1 are respectively provided with a water inlet pipe 4 and an outlet pipe 5, and both the water inlet pipe 4 and the water outlet pipe 5 are located on the top of the reactor body 1

[0060] The upper baffle 2 and the lower baffle 3 divide the reactor into six compartments along the water flow direction:

[0061] The first compartment 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com