Liner type sediment ecological restoration system

An ecological restoration and liner technology, applied in the direction of biological sludge treatment, etc., can solve the problems of affecting the activity and microbial activity, changing the shape of the lake bottom, endangering the water body and organisms, etc., to achieve easy storage and transportation, good water permeability, and good for bedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

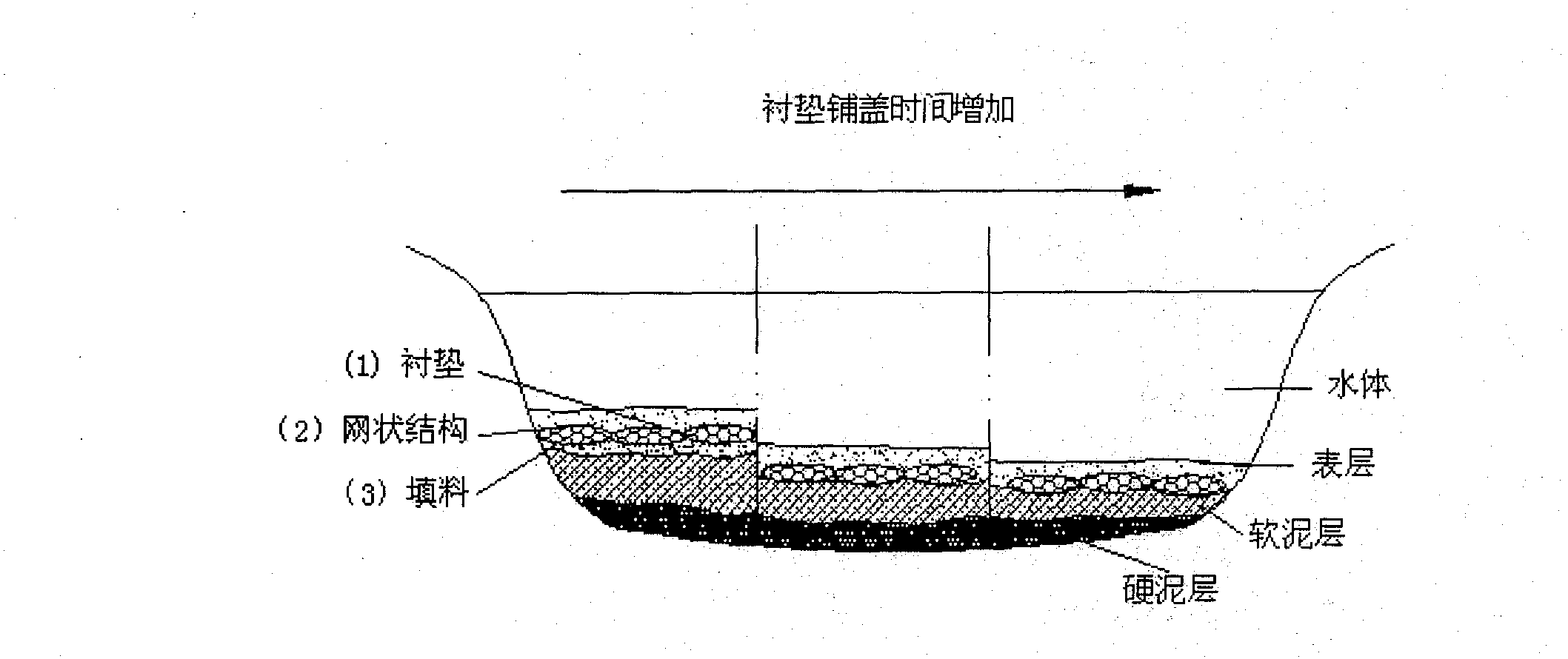

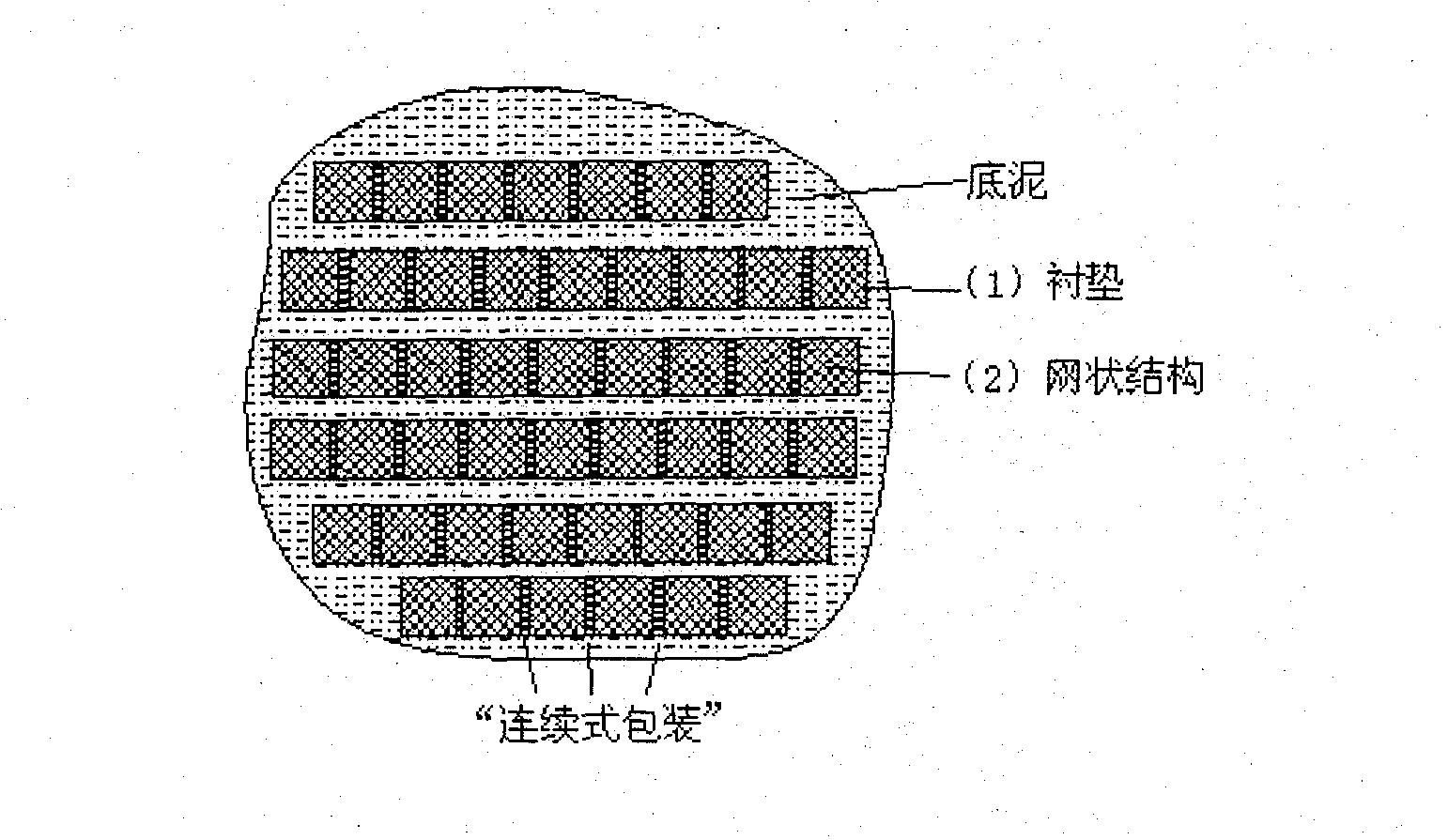

[0015] The dense mesh structure (2) of the outer layer of the liner (1) is made of anti-aging plastic, the thickness of the liner (1) is 0.1cm and the area is 49m 2 The square, the inner packing (3) adopts zeolite.

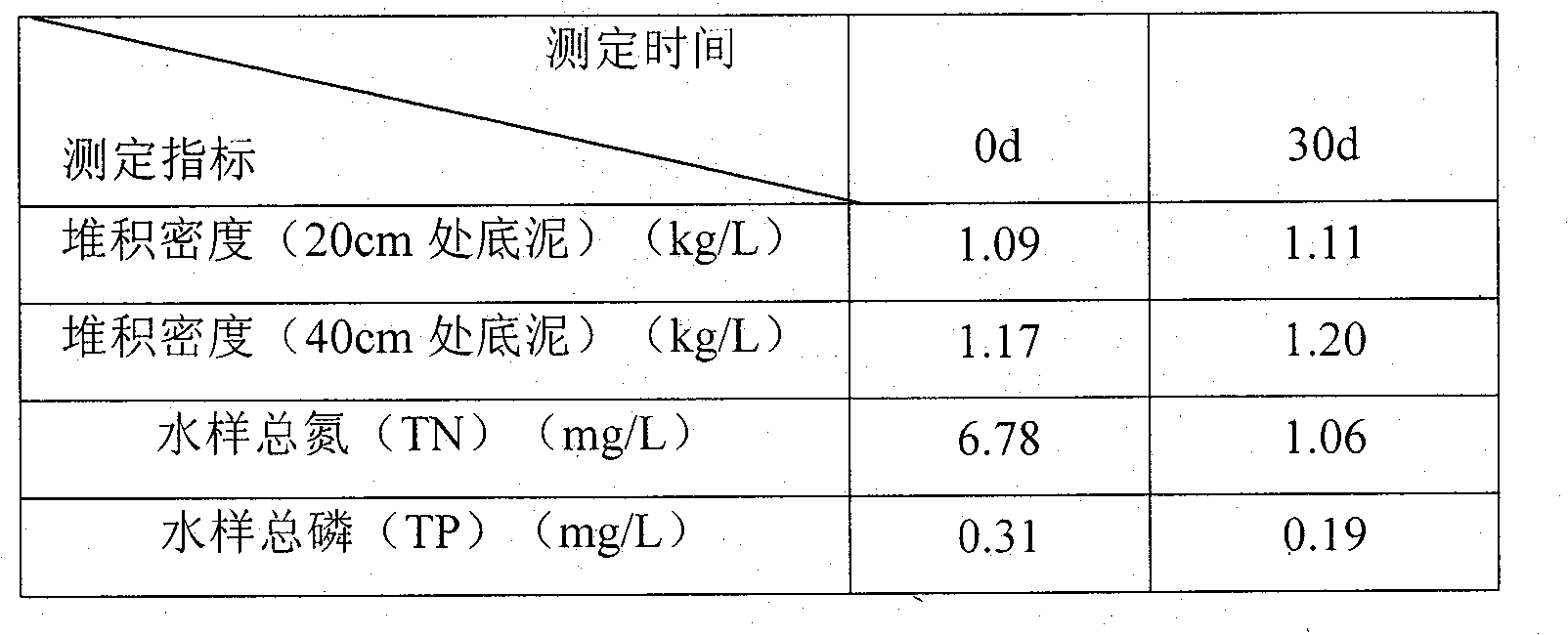

[0016] Choose within 1500m of Tianjin Urban Construction Institute 2 The artificial lake is used as the experimental site, and an area of 20 × 20 m is enclosed by an anti-seepage board as the isolation experimental area, and the liner (1) is covered on the upper part of the polluted sediment, leaving a certain gap between each two rows of liners (1). as attached figure 2 ). Select 10 points in the test area as sampling points. After the liner is covered for 30 days, use the GPS positioning system to determine the sampling point, gently lift the liner (1) with a hook, and use a large-diameter cylindrical sampler equipped with a φ110mm×1000mm PVC pipe. , and collect 10 sediment columnar samples at the lower part of the liner (1). The upper and lower ends of a...

Embodiment 2

[0021] The dense mesh structure (2) of the outer layer of the liner (1) is made of reinforcement, the thickness of the liner (1) is 25cm, and the area is 20m 2 , and the inner filler (3) is made of calcite.

[0022] The experimental environment, liner (1) covering, sediment sampling, data measurement, and standard limits are all the same as in Example 1. The measurement results are shown in Table 2:

[0023] Table 2 Changes in bulk density of sediment and the contents of TN and TP in overlying water before and after lining

[0024]

Embodiment 3

[0026] The dense mesh structure (2) of the outer layer of the liner (1) is made of anti-corrosion treated hemp rope. The thickness of the liner (1) is 50cm and the area is about 1m 2 It is nearly circular, and the inner filler (3) adopts ceramsite and adds heavy metal stabilizer.

[0027] The experimental environment, liner (1) covering, and sediment sampling are the same as those in Example 1, and the methods for measuring bulk density, TN and TP, and the standard limits of TN and TP are also the same as those in Example 1. The measurement results are shown in Table 3.

[0028] At the same time, the content of heavy metals in the sediment at 20 cm was determined. The leaching method of heavy metals in sediment is in accordance with HJ / T300-2007 "Solid Waste Leaching Toxicity Leaching Method Acetic Acid Buffer Method", and the content limit of heavy metal leaching solution refers to GB 16889-2008 "Standard for Pollution Control of Domestic Waste Landfills", and atomic absorpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com