Barium oxide based crystal lead-free glass and preparation method thereof

A technology of lead-free glass and barium oxide, applied in the field of barium oxide-based crystalline lead-free glass and its preparation, lead-free crystalline glass material and its preparation field, can solve the problem of water resistance, alkali resistance, thermal expansion system, transformation Temperature and softening temperature, crystalline glass contamination, products mixed with impurities, etc., to achieve the effect of no environmental pollution, low production cost, and meeting demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

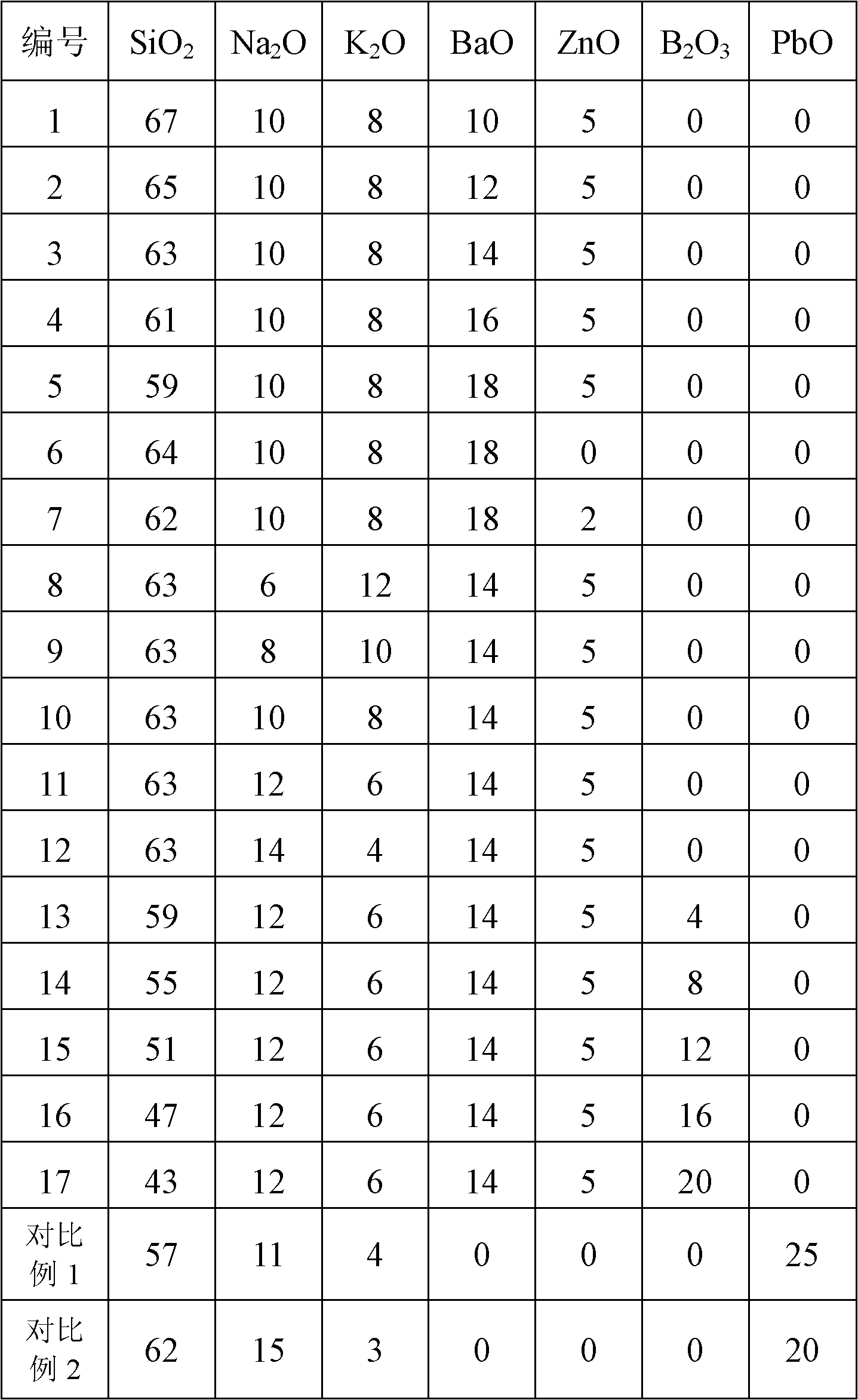

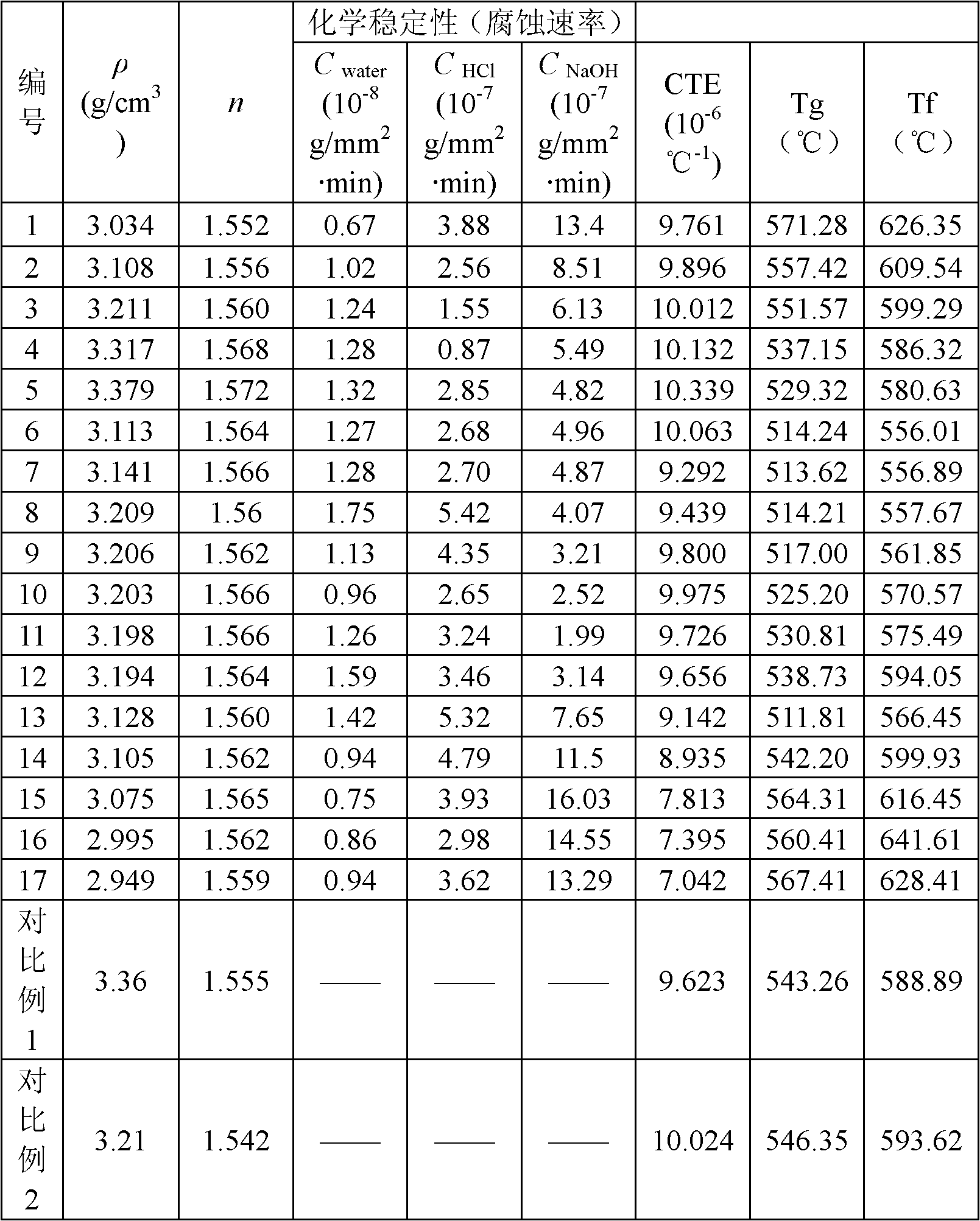

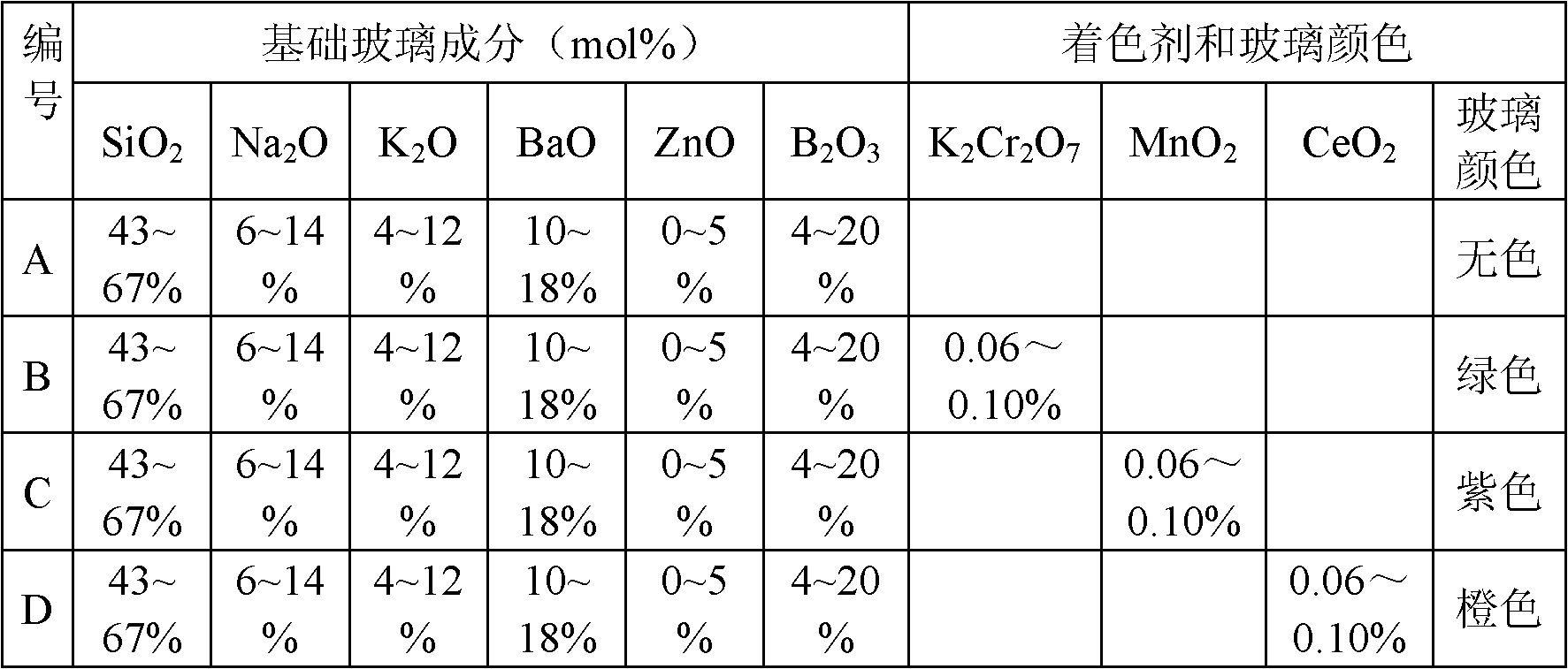

[0037] In order to further describe the technical solution of the present invention in detail, 17 specific examples and 2 comparative examples are provided. The glass formulations of each example and comparative examples are shown in Table 1. Although the formulations of the glasses are different, the specific preparation techniques and testing methods are the same. Are the same.

[0038] 1. Glass composition

[0039] The glass formulations of Examples and Comparative Examples are shown in Table 1.

[0040] 2. Preparation process

[0041] (1) Melting of glass: convert the glass chemical composition listed in Examples 1 to 17 and Comparative Examples 1 and 2 into the weight of corresponding raw materials, accurately weigh the corresponding raw materials for each composition, and ball mill the powdered raw materials , pass through an 80-mesh sieve, and mix well to obtain the batch material;

[0042] (2) Put the mixture obtained in the first step into a container such as a cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com