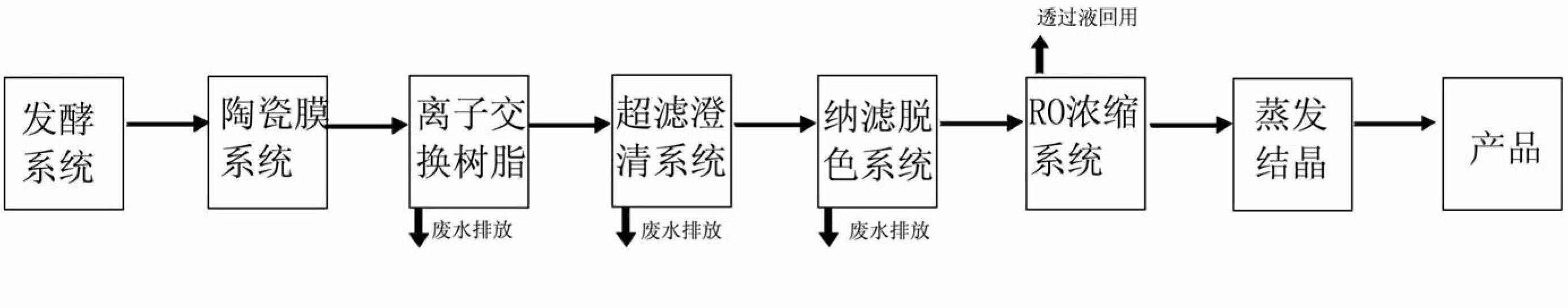

Process for purifying L-phenylalanine

A technology of phenylalanine and process, which is applied in the process field of purifying L-phenylalanine by membrane method, can solve problems such as clean production analysis, and achieve the effects of low processing cost, convenient operation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 100 tons of fermented liquid with a phenylalanine content of 4.8% is pumped into the ceramic membrane system and filtered through the ceramic membrane. The produced water enters the next step, and the concentrated water is returned to the raw material tank. When the remaining raw material liquid in the raw material tank is about 6.7 Add pure water to the raw material tank for diafiltration. The flow rate of pure water is the same as that of the product water. When the residual phenylalanine in the raw material tank is <0.5%, the diafiltration is completed, and a total of 120 tons of ceramic membrane filtrate and 5 tons of ceramic membrane filtrate are obtained. tons of concentrated liquid containing bacteria and suspended matter; the concentrated liquid obtained in this process can be used as feed and other by-products. The permeate with a content of 4% enters the ion exchange system, phenylalanine is adsorbed to the separation column, and then eluted with ammonia water ...

Embodiment 2

[0058] 100T fermented liquid with a phenylalanine content of 6% is sent to the ceramic membrane system through a water pump, and after being filtered by the ceramic membrane, the produced water enters the next step, and the concentrated water is returned to the raw material tank. When the remaining material liquid in the raw material tank is 7T, Add pure water to the raw material tank for diafiltration. The flow rate of pure water is the same as that of the product water. When the residual phenylalanine in the raw material tank is <0.5%, the diafiltration is completed, and a total of 120T ceramic membrane filtrate and 5T concentrated solution are obtained. The concentrate can be used as feed and other by-products. The phenylalanine content in the product water was 5%. The phenylalanine permeate enters the ion exchange system, adsorbs phenylalanine to the separation column, and then uses ammonia water with a concentration of 1N to elute. After completion, 240T phenylalanine fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com